Titanium dioxide coated CoSe2-based nano material as well as preparation method and application thereof

A titanium dioxide and nanomaterial technology, applied in the field of sodium ion materials, can solve the problems of charge-discharge specific capacity decay, slow reaction kinetics, unstable volume effect, etc., and achieve the effects of low contact resistance, low pollution, and promotion of interface electron transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

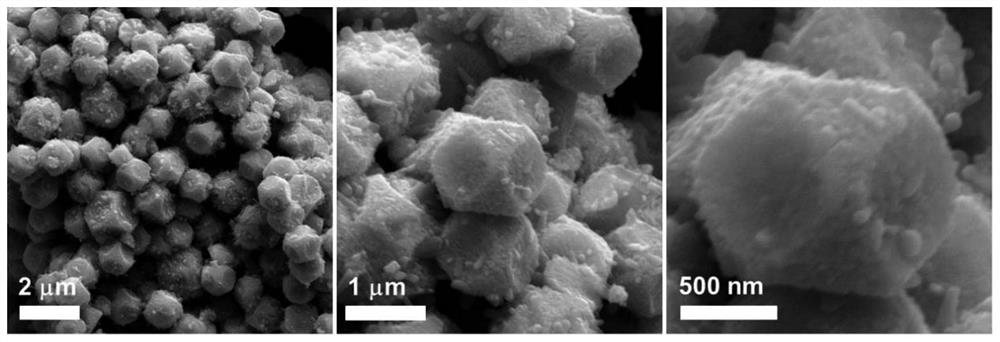

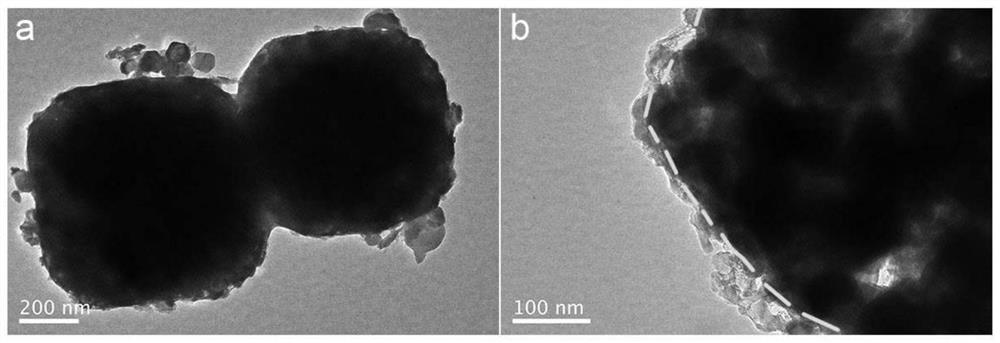

[0029] The present invention is based on the preparation of titania-coated CoSe with a Prussian blue analog template 2 The preparation method of the base nanomaterial further comprises the following steps:

[0030] (a) Weigh cobalt acetate, potassium hexacyanocarboxylate, and sodium dodecyl sulfate into a certain amount of deionized water, disperse uniformly by ultrasonic, and then stand at 25°C for 24 hours after vigorous magnetic stirring for about 1 hour. The precipitate was collected by centrifugation using absolute ethanol as the solvent, and dried at 60°C for 12 hours.

[0031] (b) The Co-Co PBA microcubes synthesized in step (a) were uniformly ultrasonically dispersed in a mixed solution of absolute ethanol and concentrated ammonia solution (28 wt%), followed by a pipette at 1 mL min. -1 The organic solution of titanium ester was added dropwise to the mixed solution at the rate of . After heating in an oil bath for 5 hours, it was allowed to stand at room temperature ...

Embodiment 1

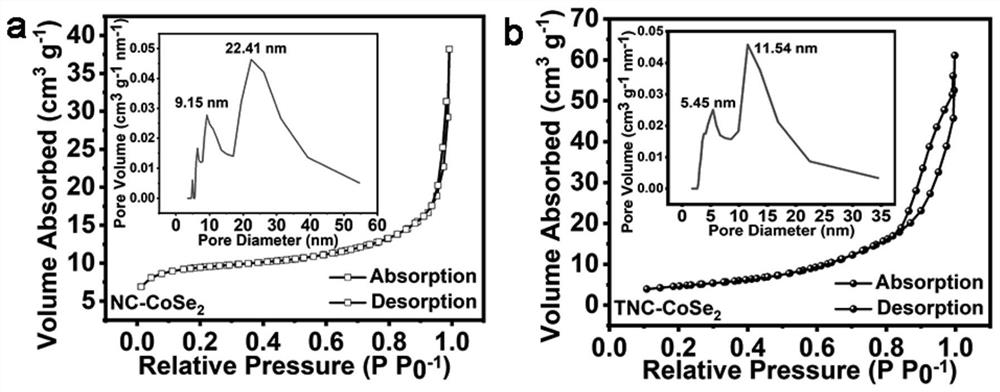

[0035] This embodiment provides a TNC-CoSe 2 The preparation method of -100 composite electrode material, which comprises the following steps:

[0036] (a) Add 0.2 g of cobalt acetate, 0.265 g of potassium hexacyanocarboxylate and 5.4 g of sodium dodecyl sulfate to 400 mL of deionized water, and ultrasonically disperse them evenly. . The precipitate was collected by centrifugation using absolute ethanol as the solvent, and dried at 60°C for 12 hours.

[0037] (b) 0.2 g of Co-Co PBA synthesized in step (a) was uniformly ultrasonically dispersed in a mixed solution of 60 mL of anhydrous ethanol and 0.15 mL of concentrated ammonia solution (28 wt%), and after ultrasonically dispersed for 30 minutes, the solution was dispersed at 1 mL min. -1 100 μL of tetrabutyl titanate (TBOT) was added dropwise to the mixed solution at a rate of . After heating in an oil bath at 80°C for 5h, it was left to stand at 25°C for 24h. Centrifuge four times using absolute ethanol as solvent, and d...

Embodiment 2

[0041] This embodiment provides a TNC-CoSe 2 The preparation method of -200 composite electrode material, which comprises the following steps:

[0042] (a) Add 0.2 g of cobalt acetate, 0.265 g of potassium hexacyanocarboxylate and 5.4 g of sodium dodecyl sulfate to 400 mL of deionized water, and ultrasonically disperse them evenly. . The precipitate was collected by centrifugation using absolute ethanol as the solvent, and dried at 60°C for 12 hours.

[0043] (b) 0.2 g of Co-Co PBA synthesized in step (a) was uniformly ultrasonically dispersed in a mixed solution of 60 mL of anhydrous ethanol and 0.15 mL of concentrated ammonia solution (28 wt%), and after ultrasonically dispersed for 30 minutes, the solution was dispersed at 1 mL min. -1 200 μL of tetrabutyl titanate (TBOT) was added dropwise to the mixed solution at a rate of . After heating in an oil bath at 80°C for 5h, it was left to stand at 25°C for 24h. Centrifuge four times using absolute ethanol as solvent, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com