Anti-depression sleep-aiding autolytic microneedle patch and preparation method thereof

A self-dissolving microneedle and anti-depressant technology, which is applied in the field of medical devices, can solve problems such as easy disintegration and adverse drug reactions, and achieve the effects of improving sleep quality, increasing sleep duration, and shortening the duration of falling asleep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation method of water-soluble CBD microcapsules

[0037] 1) Accurately weigh 100g of CBD crystal powder with a purity higher than 99% in 300ml of ethanol aqueous solution, heat at 60°C and stir for 10-30 minutes until completely dissolved, then cool to room temperature for later use.

[0038] 2) Weigh 200g of α-cyclodextrin, β-cyclodextrin, γ-cyclodextrin, and hydroxypropyl-β-cyclodextrin, respectively, add 1000g of first-grade purified water, and stir with or without heating until completely dissolved , and then add the CBD solution dissolved in step (1), and continue to stir with or without heating.

[0039] 3) Put the mixed solution prepared in step (2) into an airtight container, ultrasonically treat it with an ultrasonic generator for 1-4 hours, ultrasonic power 5000-8000W, temperature 20-60 ° C; after ultrasonic treatment, use a rotary evaporator to decompress Concentrate to remove most of the solvent and moisture. Transfer the processed ...

Embodiment 2

[0045] Embodiment 2: the preparation method of antidepressant microneedle

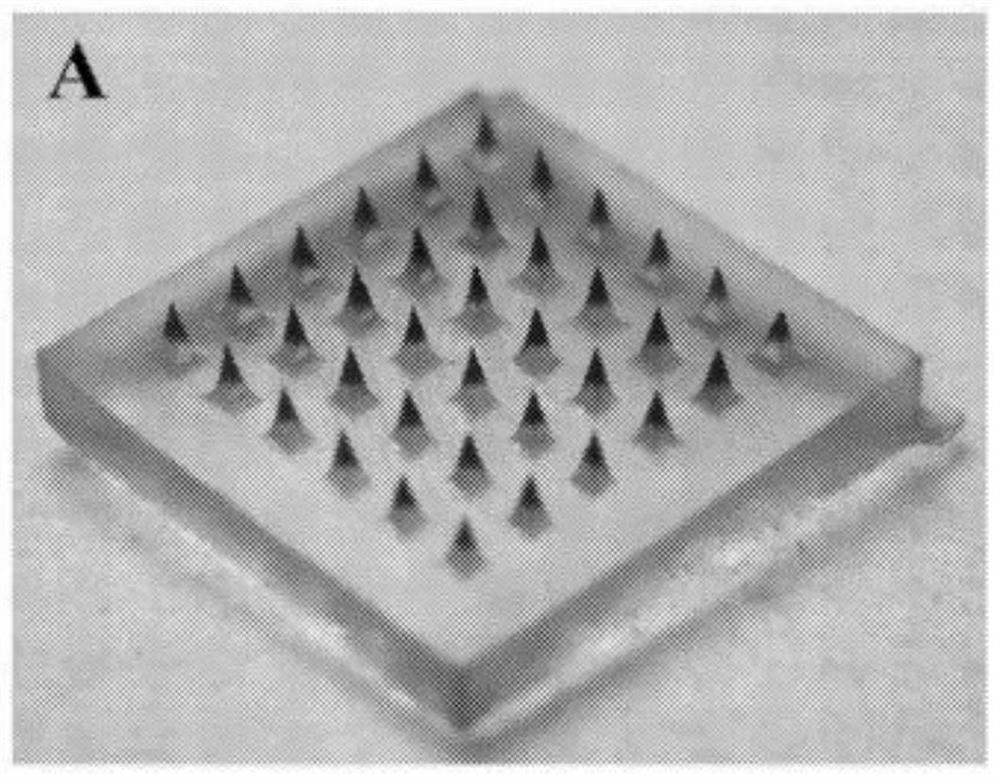

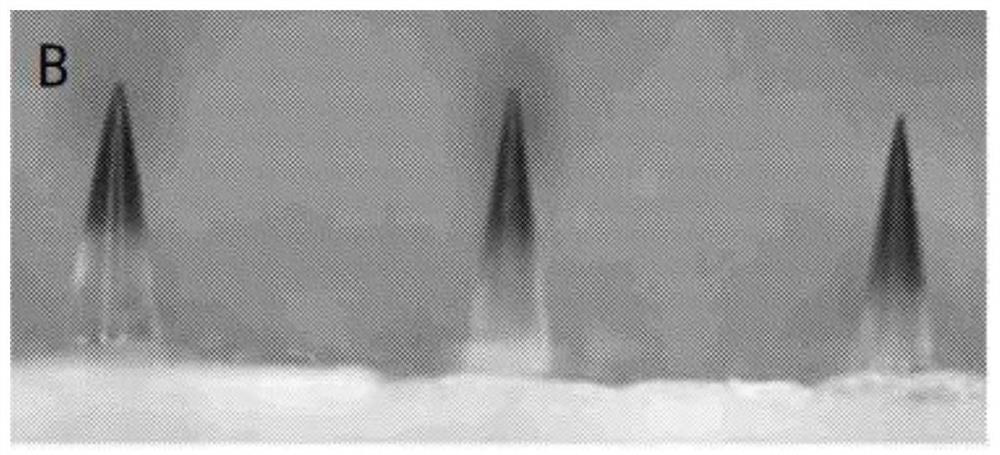

[0046] The water-soluble CBD micro-scale capsules prepared in Example 3 are mixed with sodium hyaluronate, polyvinylpyrrolidone and water, and the ratio is water-soluble CBD: sodium hyaluronate: polyvinylpyrrolidone: water=0.4:2.5:1.5: 12. All polymer solutions were centrifuged at 5000 rpm for 5 minutes to remove air bubbles. Each micro mold consists of 100 (10*10) conical (cone, triangular cone) needles, the polymer solution is introduced into the mold, and then in a vacuum environment, pressure (0.1MPa) is applied for about 10 minutes to promote polymerization The microneedle mold was centrifuged at 4500 rpm for 30 minutes to remove trapped air bubbles and the polymer solution was filled into the microneedle tips. Next, the molds were dried at 25°C for 48 hours. Finally, the microneedles are removed after drying.

Embodiment 3

[0047] Example 3: Microneedle Performance Test

[0048] 1) Needle content: observed under a microscope, it is good if it reaches 100%, good if it reaches 80%, and poor if it is less than 80%.

[0049] 2) Mechanical properties: The evaluation standard is that it can pass through the aluminum foil paper as good, and can not pass through the aluminum foil paper as poor.

[0050] 3) Hygroscopicity: The evaluation standard is that the hygroscopicity of microneedles that can pass through more than 2 layers of aluminum foil paper smoothly after being placed in a high-humidity environment for 12 hours is good, and the hygroscopicity of microneedles that can only pass through 1 layer of aluminum foil paper is medium, and cannot be The hygroscopicity of the microneedles passing through the aluminum foil was poor.

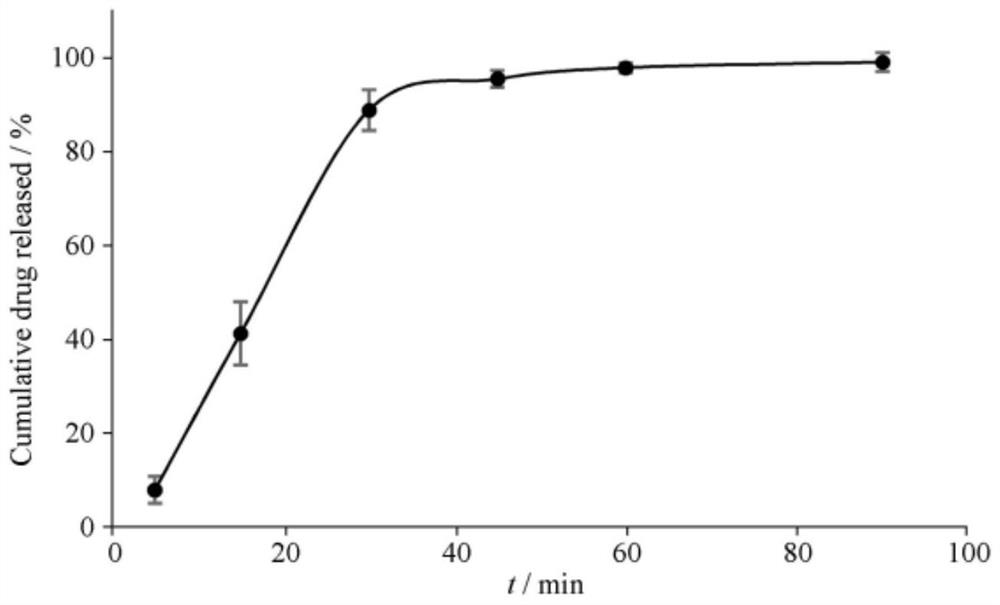

[0051] 4) Release: Franz transdermal diffusion cell was used to evaluate the in vitro release performance of the prepared CBD self-dissolving microneedle patch. Fix the CBD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com