Ceramic/graphene aerogel wave-absorbing material as well as preparation method and application thereof

A graphene aerogel, wave absorbing material technology, applied in ceramic products, applications, other household appliances, etc., can solve the problems of poor impedance matching, poor wave absorbing performance, difficult absorption of electromagnetic waves, etc., to achieve low cost, repeatability Good, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

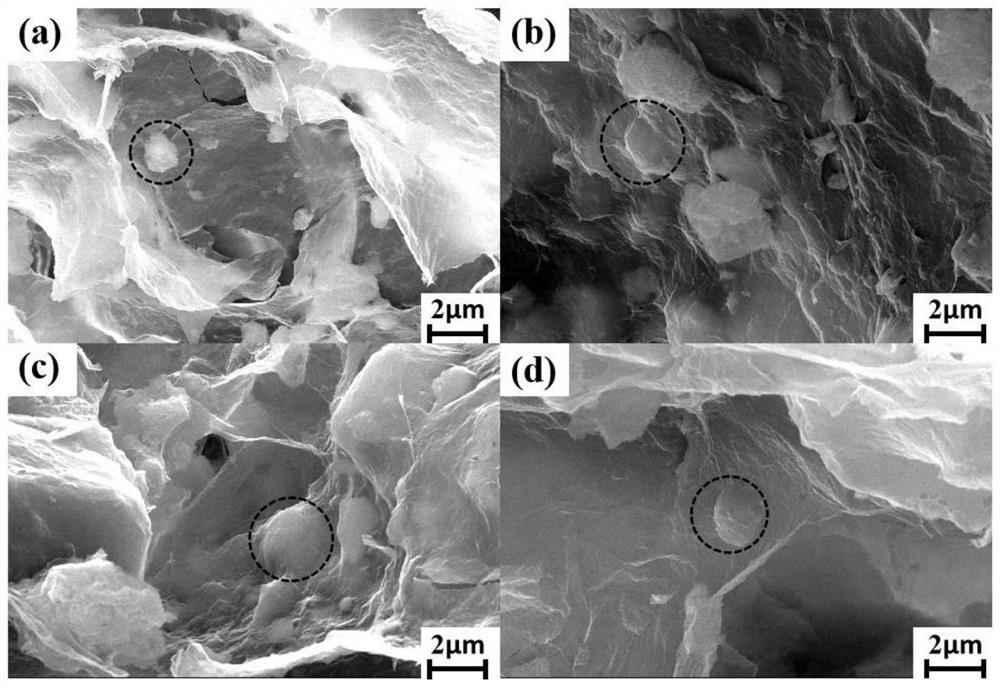

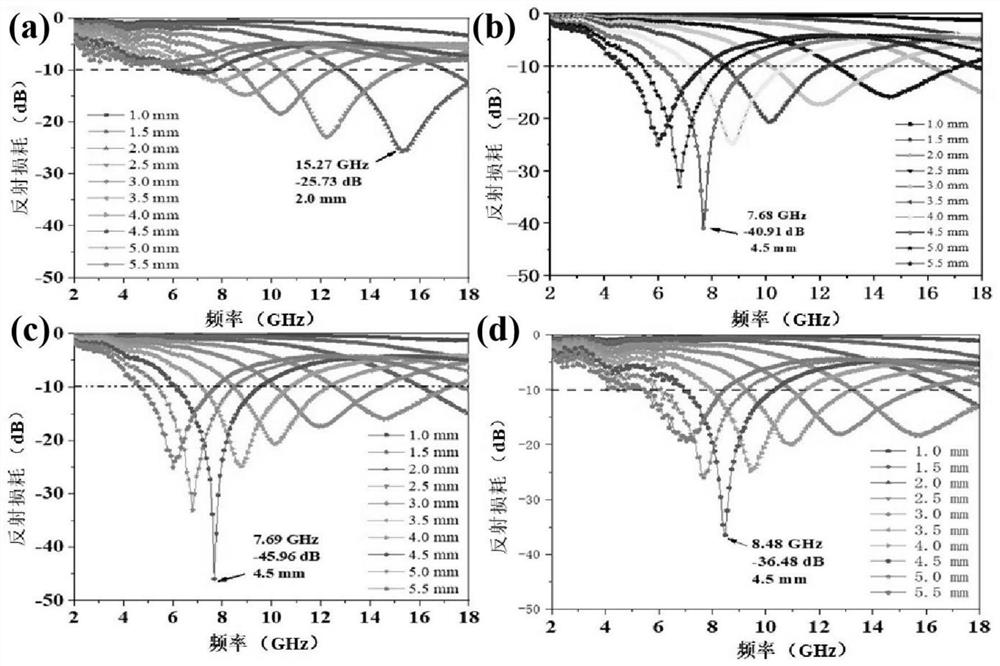

Embodiment 1

[0047] In step 1, 1 mol of Al(NO 3 ) 3 ·9H 2 O was dissolved in 500 mL of deionized water to obtain Al(NO) with a concentration of 2 mol / L 3 ) 3 solution, heating Al(NO 3 ) 3 The solution was brought to 75°C, and ammonia water was added dropwise with mechanical stirring until boehmite sol was formed; 1 mol LiNO 3 Dissolved in 500 mL of deionized water to obtain LiNO with a concentration of 2 mol / L 3 solution, the above LiNO 3 The solution was added to the boehmite sol and stirred at 300r / min for 2h to obtain a lithium-aluminum solution; take 400mg SiO 2 The sol was slowly added dropwise to the above lithium-aluminum solution and stirred at a speed of 300 r / min for 4 hours to obtain a lithium-aluminum-silica sol; the above-mentioned lithium-aluminum-silica sol was dried at 100 °C for 48 hours to obtain LAS precursor powder; the LAS precursor powder was heat-treated at 800 °C After 12h (the purpose is to remove nitrate and water), grind to obtain lithium aluminum silicon...

Embodiment 2

[0051] Step 1 is the same as Step 1 in Example 1.

[0052] Step 2: Weigh 2.0g of LAS powder, dissolve it in 30mL of deionized water, stir evenly, put it into an ultrasonic dispersing oscillator at room temperature for 30min to obtain a ceramic powder dispersion; weigh 2.5g of graphene oxide and put it in a beaker, add it to the beaker. Add 30mL of ceramic powder dispersion liquid to it, then dilute to 80mL, then put the beaker in the ultrasonic dispersion oscillator for 1h at room temperature, add 0.5g of urea CO (NH 2 ) 2 Stir until dissolved completely to obtain a mixed solution.

[0053] Step 3 is the same as Step 3 in Example 1. A nitrogen-doped modified lithium-aluminum-silicon / graphene composite material (N-LAS / rGO) is obtained, that is, a ceramic / graphene aerogel wave absorbing material.

Embodiment 3

[0055] Step 1 is the same as Step 1 in Example 1.

[0056] Step 2: Weigh 2.0g of LAS powder, dissolve it in 30mL of deionized water, stir evenly, put it into an ultrasonic dispersing oscillator at room temperature for 30min to obtain a ceramic powder dispersion; weigh 2.5g of graphene oxide and put it in a beaker, add it to the beaker. Add 30 mL of ceramic powder dispersion liquid to it, and then dilute it to 80 mL. After that, put the beaker in the ultrasonic dispersion oscillator for 1 hour at room temperature, and then add 1 g of urea CO (NH 2 ) 2 Stir until dissolved completely to obtain a mixed solution.

[0057] Step 3 is the same as Step 3 in Example 1. A nitrogen-doped modified lithium-aluminum-silicon / graphene composite material (N-LAS / rGO) is obtained, that is, a ceramic / graphene aerogel wave absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Reflection loss value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com