PETG (polyethylene terephthalate glycol) and method for preparing PETG from waste PET polyester

A polyester and waste technology, applied in the field of waste alcohol ester utilization, can solve the problems of large carbon emissions and consumption of original resources, achieve stable performance, reduce waste generation, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

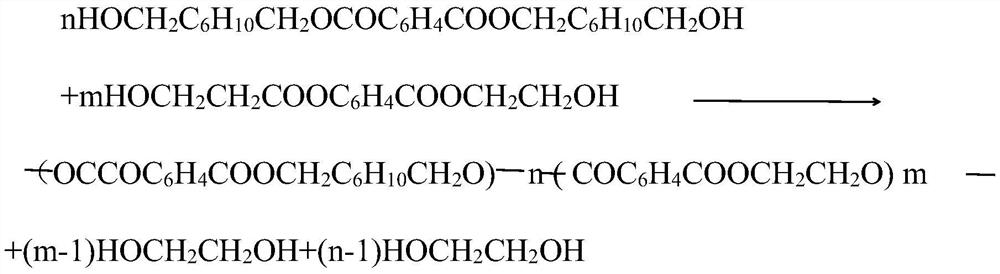

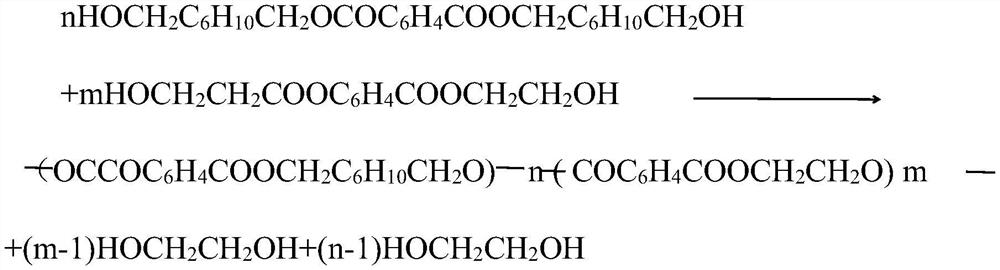

Method used

Image

Examples

Embodiment 1

[0084] Example 1: Preparation of recycled PETG chips

[0085] Preparation of DMT: Depolymerization of waste PET polyester to obtain BHET monomer, and the first transesterification reaction of BHET monomer and methanol to obtain DMT;

[0086] The variegated leftovers containing PET (86wt%) after impurity removal were made into aggregated pellets by a pelletizer system; the 100KG aggregated pellets were melted and extruded with a screw to form a melt; the melt was filtered by a melt filter and then transported to In the depolymerization kettle; additionally, 130KG of EG depolymerization solution and 0.02KG of depolymerization catalyst zinc acetate were metered into the depolymerization kettle into the depolymerization kettle, and the depolymerization reaction was carried out to obtain the BHET monomer.

[0087] First transesterification:

[0088]The first transesterification reaction between BHET monomer and 150KG methanol (MEOH) was carried out to obtain DMT;

[0089] The DMT...

Embodiment 2

[0102] The difference between Example 2 and Example 1 is: in the secondary transesterification step, the reaction temperature is controlled at 220 to 230 ° C; the prepolymer is generated: BHCT and BHET are removed from ethylene glycol to form a prepolymer, and the reaction temperature is controlled at 260 to 260 ° C. 270°C; prepolymer polymerization: the prepolymer is polymerized, and the reaction temperature is controlled at 295-305°C; vacuum is applied until the reaction pressure reaches 80 Pa (A).

[0103] Example 2 The product through the analysis index is: viscosity 0.736dl / g, chromaticity (L value 65.8, b value 0.6), is a transparent amorphous material, excellent index, good transparency, chemical corrosion resistance, impact resistance, easy to process injection molding , all meet the needs of market film applications, polyester bottle applications, etc.

Embodiment 3

[0105] The difference between Example 3 and Example 1 is: in the secondary transesterification step, the reaction temperature is controlled at 170 to 180 ° C; the prepolymer is generated: BHCT and BHET are removed from ethylene glycol to generate a prepolymer, and the reaction temperature is controlled at 240 to 180 ° C. 250°C; prepolymer polymerization: the prepolymer is polymerized, and the reaction temperature is controlled at 270-280°C; vacuum is applied until the reaction pressure reaches 40 Pa (A).

[0106] Example 3 The product through the analysis index is: viscosity 0.739dl / g, chromaticity (L value 65.1, b value 0.82), is a transparent amorphous material, excellent index, good transparency, chemical corrosion resistance, impact resistance, easy to process injection molding , all meet the needs of market film applications, polyester bottle applications, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com