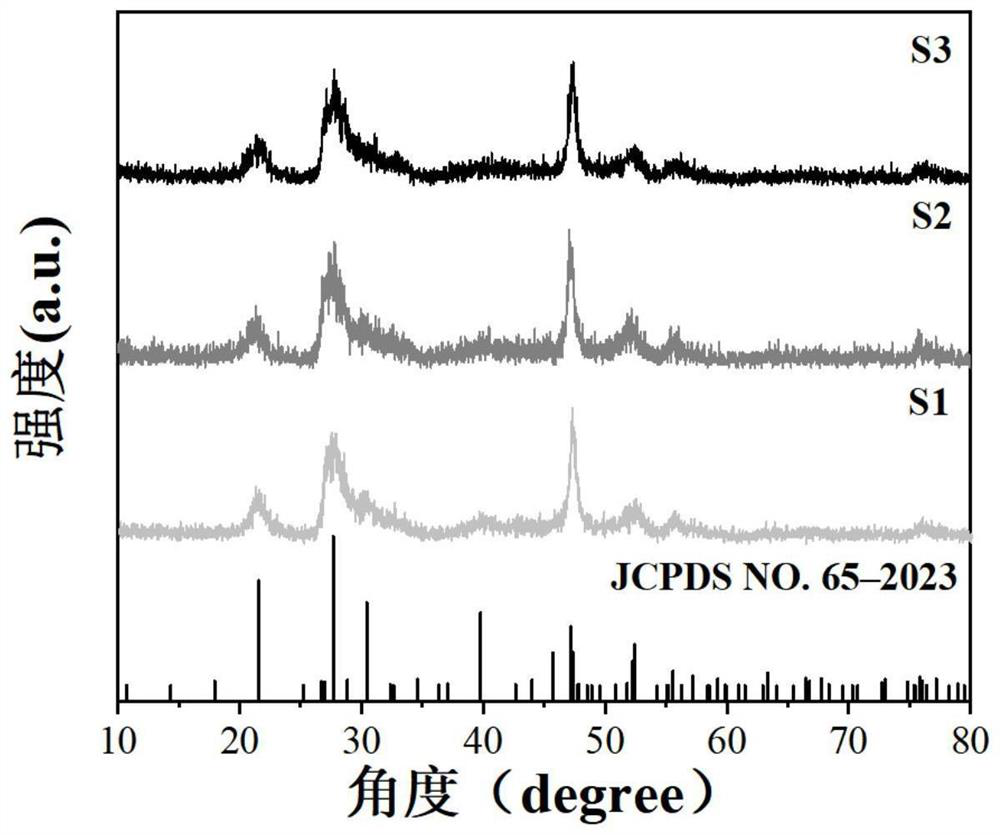

Triethylamine gas sensor based on sulfur-rich vacancy ZnIn2S4 nanoflower sensitive material and preparation method of triethylamine gas sensor

A gas sensor and sensitive material technology, applied in the direction of material resistance, air quality improvement, etc., can solve problems such as lattice sulfur vacancy defects, and achieve the effects of good detection performance, suitable for mass production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Processing of Pd metal interdigital electrodes:

[0031] Wipe Al with Pd metal interdigital electrodes with acetone and ethanol cotton balls respectively 2 O 3 The substrate is clean, and then Al with Pd metal interdigitated electrodes 2 O 3 The substrates were sequentially placed in acetone, ethanol and deionized water, ultrasonically cleaned for 5 minutes, and finally dried at 100 °C;

[0032] The present invention uses screen printing technology on Al 2 O 3 Pd metal interdigital electrodes are prepared on the substrate. The specific method is as follows: Mix the ink [Jiahua JX07500487], Pd powder and diluent in a mass ratio of 1:1:2, stir to prepare a paste; then inject the paste into onto a screen plate with an interdigitated electrode pattern, scrape the paste at an inclination angle of 30° and a pressure of 5 N, in Al 2 O 3 The interdigital electrodes are printed on the substrate and dried, and the preparation of Pd metal interdigital electrodes is compl...

Embodiment 2

[0039] The processing procedure of the Pd metal interdigital electrode is the same as that of Example 1.

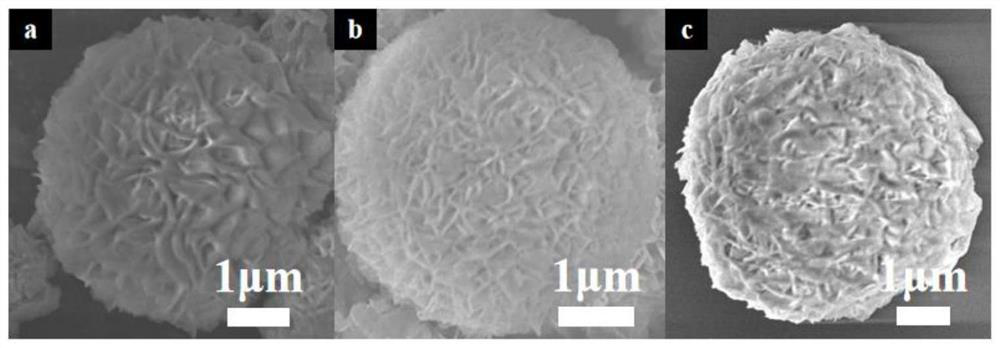

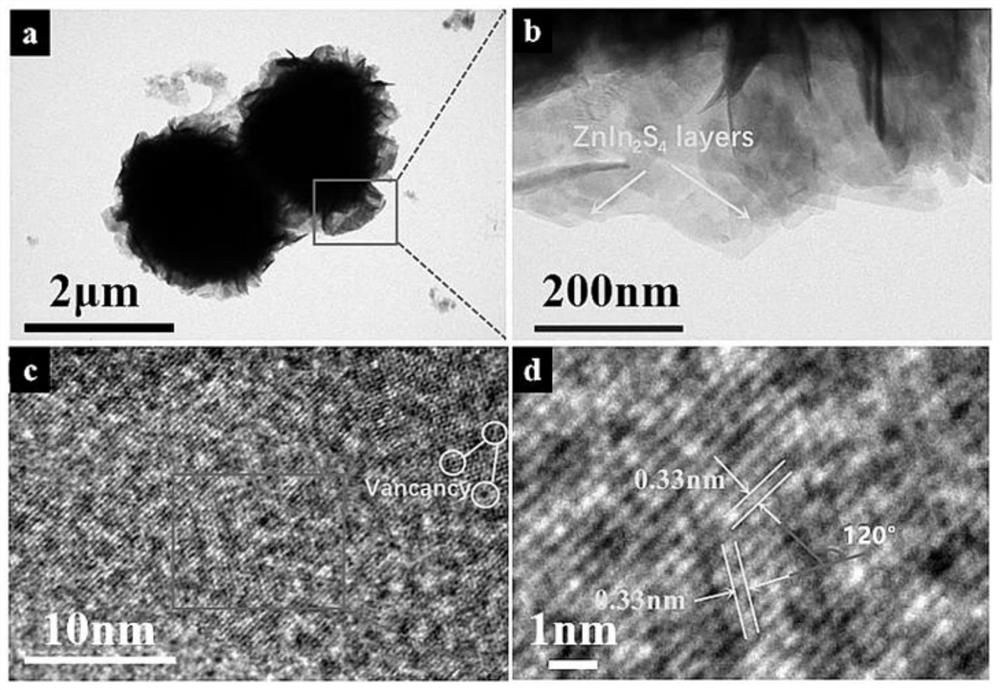

[0040] At room temperature, a metal precursor with a fixed stoichiometric ratio of 1:2 consisting of 0.29 g of zinc nitrate hexahydrate and 0.44 g of anhydrous indium chloride was dissolved in 60 mL of deionized water. Then 0.45 g of thioacetamide, 0.06 g of citric acid and 0.02 g of polyethylene glycol (PEG, 2000 MW) were added to the solution, and vigorously stirred for 20 min. The above solution was transferred to a reactor and reacted at 160 °C for 12 h; after cooling to room temperature, the resultant was centrifuged with ethanol, and the centrifuged product was dried at 60 °C for 24 hours, thereby obtaining a nanosheet assembled based on {0001} crystal planes. Sulfur-rich vacancy ZnIn 2 S 4 Nanoflower sensitive material, the product mass is 0.41g.

[0041] Sulfur-rich vacancy ZnIn assembled based on {0001} faceted nanosheets 2 S 4 Preparation of gas sensor of n...

Embodiment 3

[0043] The preparation process of the Pd metal interdigital electrode is the same as that of Example 1.

[0044] At room temperature, a metal precursor with a fixed stoichiometric ratio of 1:2 consisting of 0.29 g of zinc nitrate hexahydrate and 0.44 g of anhydrous indium chloride was dissolved in 60 mL of deionized water. Then, 0.60 g of thioacetamide, 0.09 g of citric acid and 0.02 g of polyethylene glycol (PEG, 2000 MW) were added to the solution, and vigorously stirred for 20 min. The above solution was transferred to a reactor and reacted at 160 °C for 12 h; after cooling to room temperature, the resultant was centrifuged with ethanol, and the centrifuged product was dried at 60 °C for 24 hours, thereby obtaining a nanosheet assembled based on {0001} crystal planes. Sulfur-rich vacancy ZnIn 2 S 4 Nanoflower sensitive material, the product mass is 0.42g.

[0045] Sulfur-rich vacancy ZnIn assembled based on {0001} faceted nanosheets 2 S 4 Preparation of gas sensor of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com