Graphene-based selenium positive electrode material embedded with two-dimensional metal selenide, preparation method of graphene-based selenium positive electrode material and lithium-selenium battery

A metal selenide and graphene-based technology, applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of shuttle effect, slow reaction kinetics of lithium-selenium batteries, etc., and achieve low cost and easy large-scale production Promotion and application, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The present invention also provides a preparation method of the graphene-based selenium composite material, comprising the following steps:

[0080] 1) After grinding and mixing the metal selenide / graphene composite material and the selenium powder, under vacuum conditions, after hot-melting treatment, the graphene-based selenium composite material is obtained.

[0081] In the present invention, the temperature of the hot melt treatment is preferably 240 to 280°C, more preferably 245 to 275°C, more preferably 250 to 270°C, and more preferably 255 to 265°C.

[0082] In the present invention, the time of the hot melt treatment is preferably 12-24 hours, more preferably 14-22 hours, and more preferably 16-20 hours.

[0083] In the present invention, the preparation method of the metal selenide / graphene composite material preferably comprises the following steps:

[0084] After mixing metal salt, graphene oxide and mixed solvent, adding selenium and reducing agent, solvoth...

Embodiment 1

[0109] Put 0.3mmol of Na 2 MoO 4 ·2H 2 Add 50mL GO mixed solution (H 2 O:DMF=2:3) (1 mg / mL). Ultrasonic dispersion was uniform, then 20 mL of selenium hydrazine hydrate solution was added, stirred evenly, and then transferred to a 100 mL hydrothermal kettle, hydrothermally heated at 200 °C for 12 h, washed, dried, and treated at 1000 °C for 2 h to obtain a molybdenum diselenide / graphene composite material.

[0110] The molybdenum diselenide / graphene composite material prepared in Example 1 of the present invention was characterized.

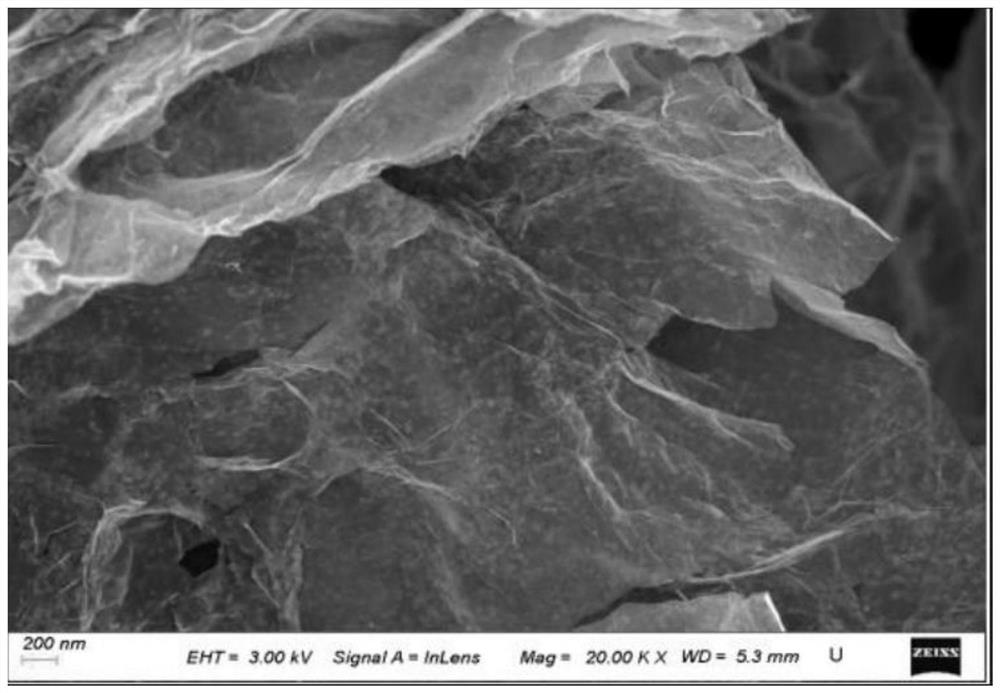

[0111] see figure 1 , figure 1 The high-magnification SEM scanning electron microscope picture of the molybdenum diselenide / graphene composite material prepared by the present invention.

[0112] Depend on figure 1 It can be clearly seen that the two-dimensional sheets of molybdenum diselenide are uniformly dispersed on the graphene sheets.

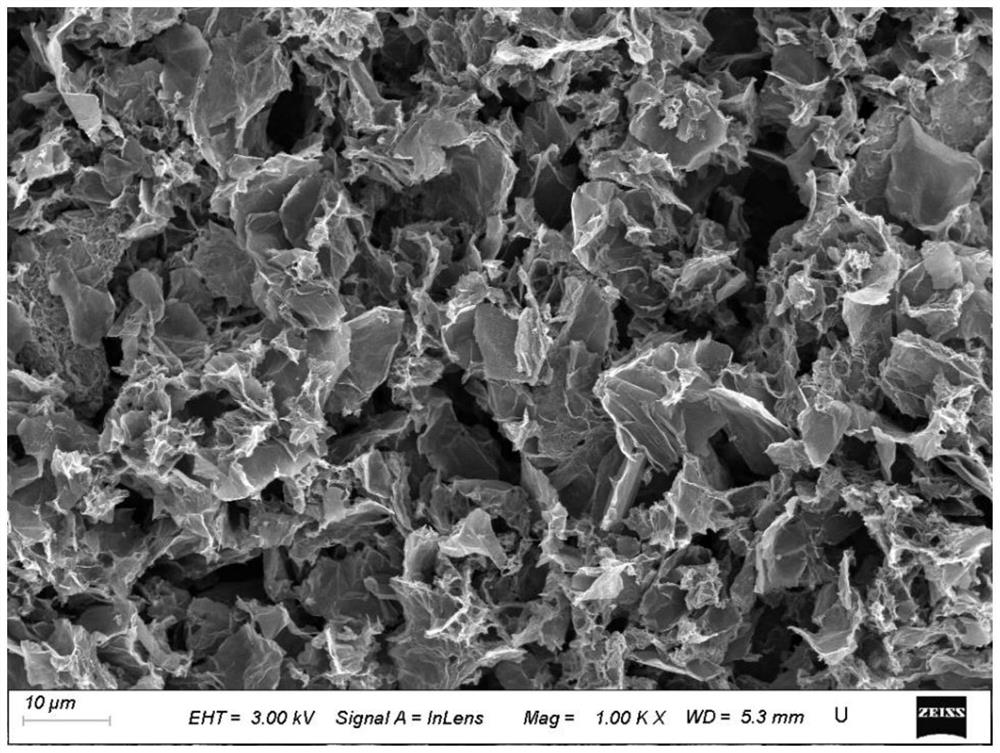

[0113] see figure 2 , figure 2 The low-magnification SEM scanning electron microscope picture...

Embodiment 2

[0118] Put 0.3mmol of Na 2 WO 4 ·2H 2 Add 50mL GO mixed solution (H 2 O:DMF=2:3) (1 mg / mL). Ultrasonic dispersion was uniform, then 20 mL of selenium hydrazine hydrate solution was added, stirred evenly, and then transferred to a 100 mL hydrothermal kettle, hydrothermally heated at 200 °C for 12 h, washed, dried, and treated at 1000 °C for 2 h to obtain a tungsten diselenide / graphene composite material.

[0119] The tungsten diselenide / graphene composite material and selenium powder were ground and mixed uniformly at a ratio of 3:7, transferred to a sealed vacuum glass tube, and treated at 260 °C for 20 h. A selenium positive electrode material is obtained.

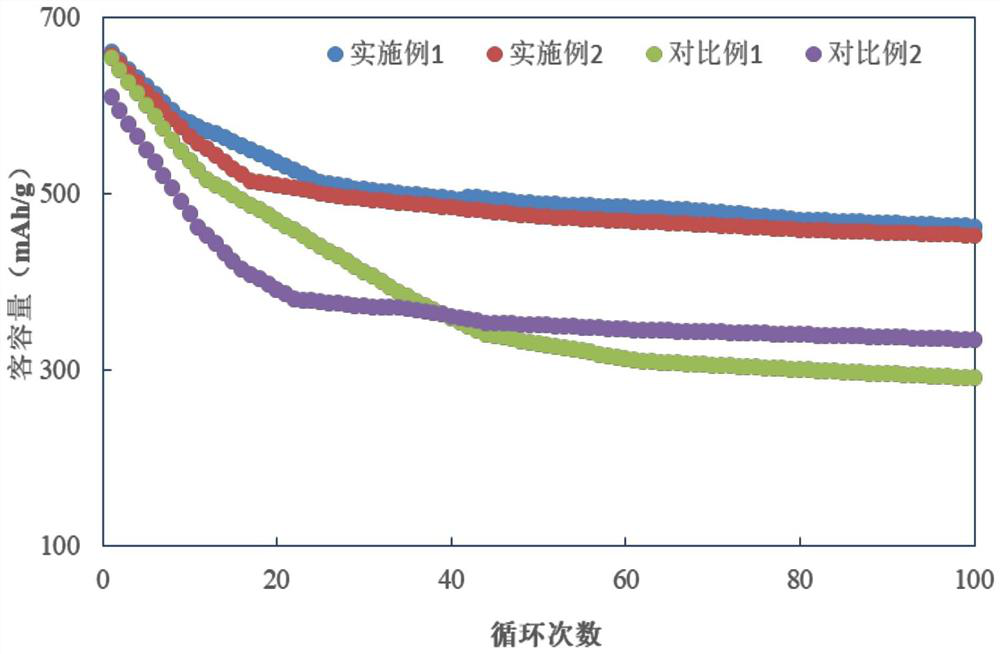

[0120] The performance of the selenium cathode material prepared in Example 2 of the present invention was tested, see Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com