Preparation and application of adsorption-catalysis bifunctional material capable of synchronously removing COD (Chemical Oxygen Demand), antibiotics and phosphorus in aquaculture sewage

A bifunctional material and aquaculture sewage technology, which is applied in the field of bifunctional material preparation and water treatment, can solve the problems of unreasonable application of antibiotics, reduction of various pollutants in aquaculture sewage, excessive consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

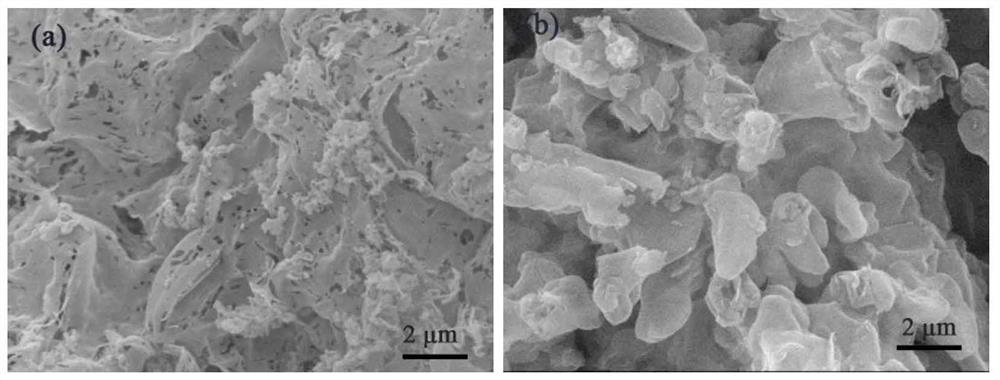

[0036] Weigh 250 g of melamine into a 500 mL alumina crucible with a lid, and place the crucible in a muffle furnace at 2 °C min. -1 The temperature was slowly raised to 600 °C at a rate of 4 h and kept at this temperature for 4 h. After natural cooling, the light yellow blocky solid was taken out and ground into powder to obtain a calcined g-C 3 N 4 (like figure 1 shown in (a)); the g-C calcined once 3 N 4 Put it back into the muffle furnace at 8 ℃·min -1 The temperature was raised to 550 °C at a rate of 2 h, and the temperature was maintained for 2 h. After natural cooling, the product was taken out, and finally light yellow powdery ultrathin carbon nitride nanosheets g-C were obtained. 3 N 4 (like figure 1 shown in (b)). can clearly see figure 1 The primary calcined g-C exhibited by (a) in 3 N 4 It is a two-dimensional overall lamellar structure with a fluffy and rough surface; figure 1 (b) of the ultrathin carbon nitride nanosheets g-C 3 N 4 It is a more "frag...

Embodiment 2

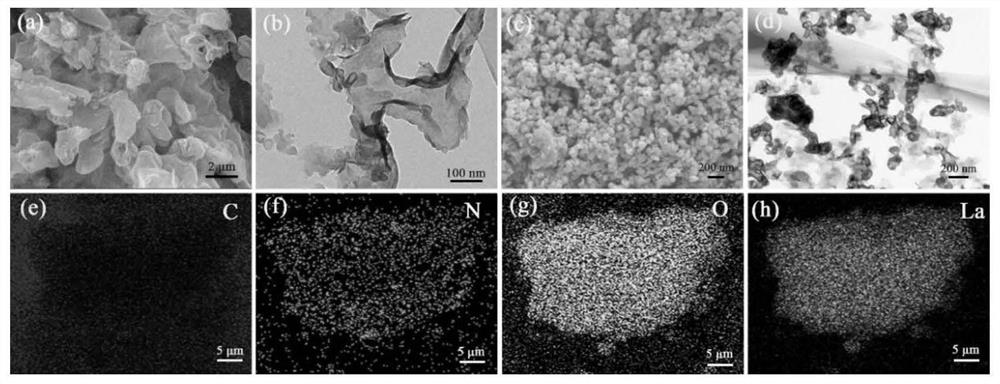

[0038] Accurately weigh 3 g of the ultrathin carbon nitride nanosheets g-C prepared in Example 1 3 N 4 (which was obtained after the first and second calcinations), 1.083 g La (NO 3 ) 3 ·6H 2 O and 0.9607 g of citric acid (as a protective agent) were added to 100 ml of 50% ethanol solution, and stirred magnetically for 30 min; quickly added 20 ml of 0.2 mol·L to the beaker. -1 The KOH solution was again magnetically stirred for 30 min, and then transferred to a 250 mL hydrothermal reactor, reacted in a 200 ℃ oven for 10 h, cooled to room temperature, and the product was taken out (the product here refers to g-C 3 N 4 , La(NO 3 ) 3 ·6H 2 O, citric acid, ethanol solution and KOH solution were mixed and then added to the hydrothermal reactor, and the product was obtained by reacting in an oven at 200 °C for 10 h. The product was a solid-liquid mixture without solid-liquid separation). Washed with deionized water for 4 times (that is, washed with absolute ethanol for 4 tim...

Embodiment 3

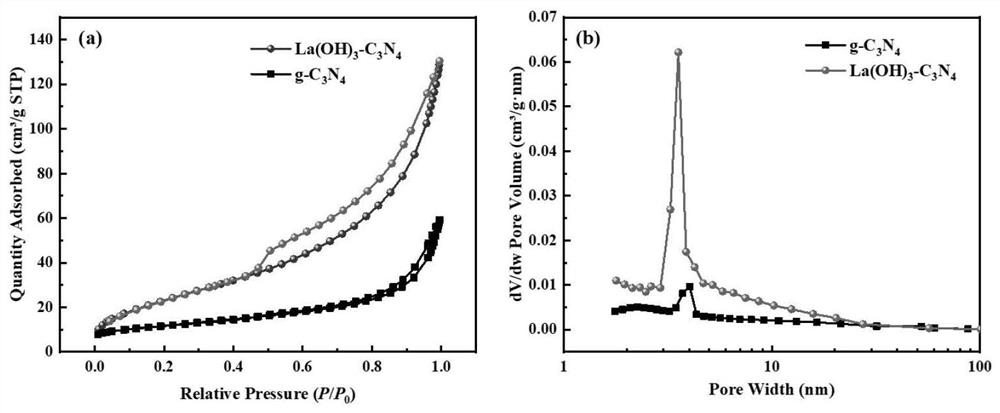

[0043] In this example, by adding g-C 3 N 4 (that is, the ultrathin carbon nitride nanosheets g-C obtained by the first calcination and the second calcination in Example 1 3 N 4 ), La(OH) 3 and La(OH) 3 -C 3 N 4 The phosphate adsorption capacity of three different materials was investigated, La(OH) in this example 3 -C 3 N 4 The preparation method is the same as that of Example 2. Use potassium dihydrogen phosphate to prepare several 20 mg / L phosphate solutions (50 mL), each weighing 5 mg of g-C 3 N 4 , La(OH) 3 and La(OH) 3 -C 3 N 4 The material was tested, and the adsorption amount of phosphate and the utilization rate of lanthanum were calculated after the adsorption equilibrium. The experimental results see Figure 4 : The saturated adsorption capacity of the three materials is 18.99 mg·g, respectively -1 , 142.39 mg g -1 and 137.78 mg g -1 , g-C 3 N 4 The adsorption capacity is only about 1 / 7 of that of lanthanide materials. The lanthanum content (La...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com