Modified carbon fiber/phenolic resin composite material and preparation method thereof

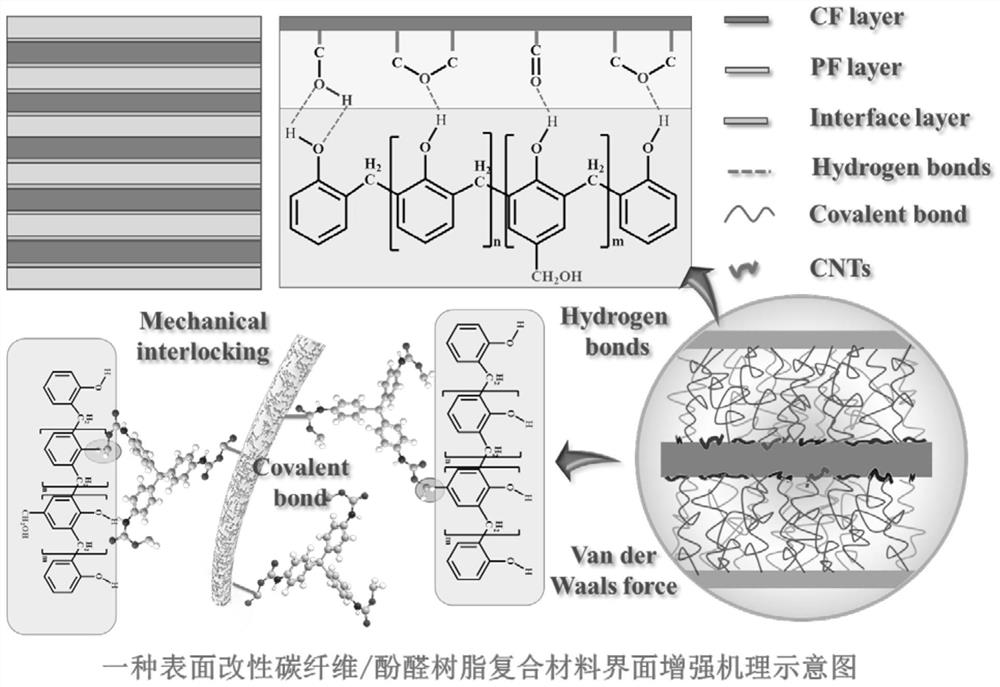

A technology of phenolic resin and composite materials, which is applied in the field of composite materials, can solve the problems of uneconomical and high cost, and achieve the effects of increasing the contact area, improving performance, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

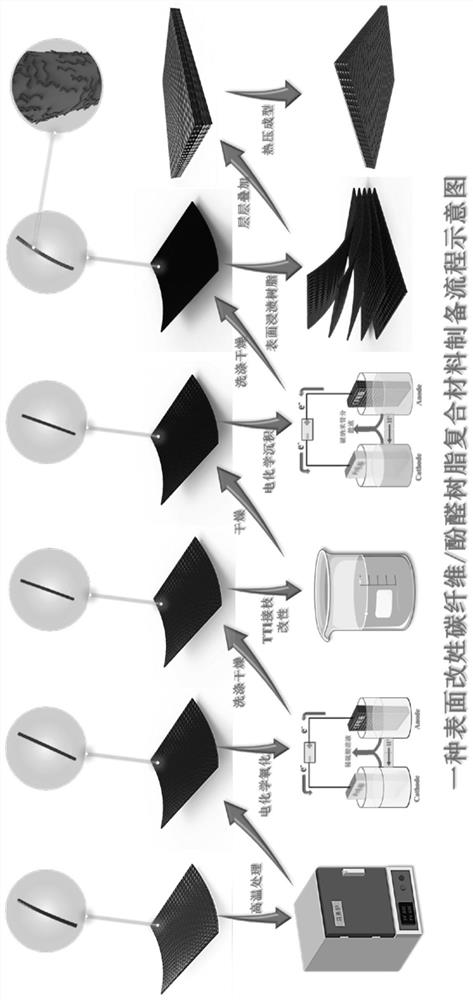

[0049] A carbon fiber surface modification technology is characterized in that comprising the following operation steps:

[0050] (1) Remove the sizing agent on the surface of the original carbon fiber at high temperature: put the 10*10cm size T300 carbon fiber cloth into the muffle furnace for high temperature treatment, the treatment temperature is set to 400 ℃, and the working time is 120min;

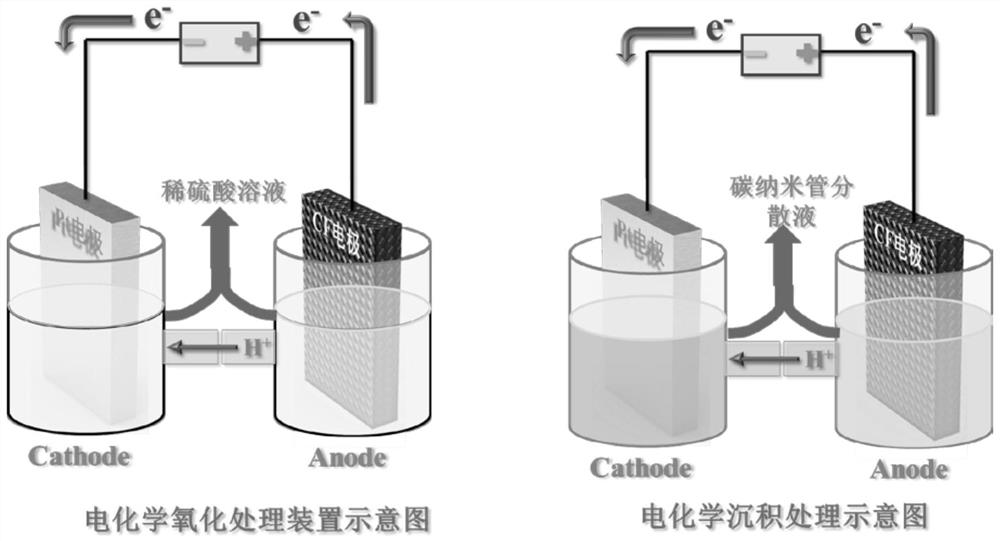

[0051] (2) Electrochemical oxidation: the carbon fiber after the high temperature treatment in step (1) is put into the electrolysis reaction tank as the electrolytic anode material, the electrolyte is selected as a dilute sulfuric acid solution with a volume fraction of 40%, the cathode material is selected as a platinum electrode, and the electrolysis voltage is 5V , the electrochemical treatment time is 20min;

[0052] (3) washing: at room temperature, the carbon fiber after the electrochemical treatment of step (2) is washed and suction filtered with washing solution, the washing...

Embodiment 2

[0061] Other conditions are the same as in Example 1, except that in step (1), the temperature during high temperature treatment is 300°C.

Embodiment 3

[0063] Other conditions are the same as in Example 1, except that in step (1), the temperature during high temperature treatment is 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com