Thin-film semiconductor and semiconductor device and thin-film transistor mfg method

一种半导体、器件的技术,应用在薄膜半导体领域,能够解决无法控制位置等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

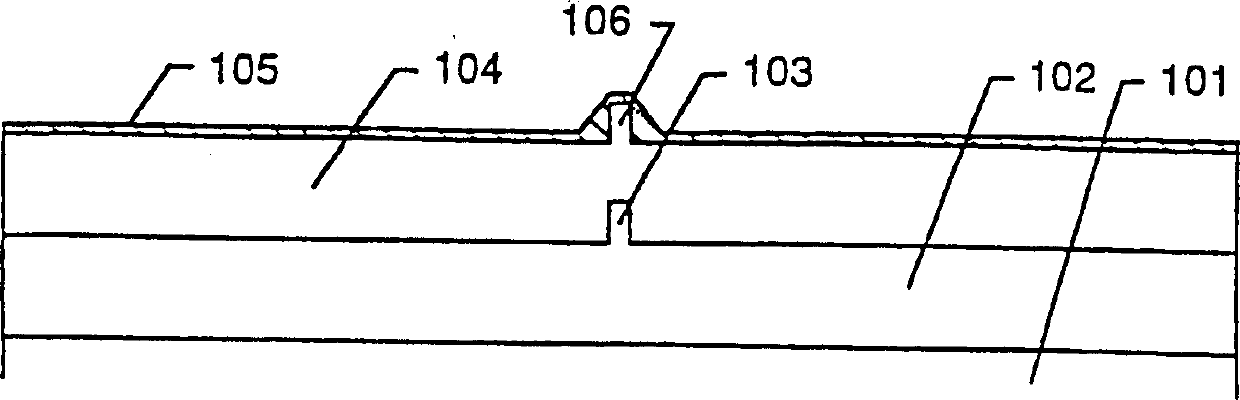

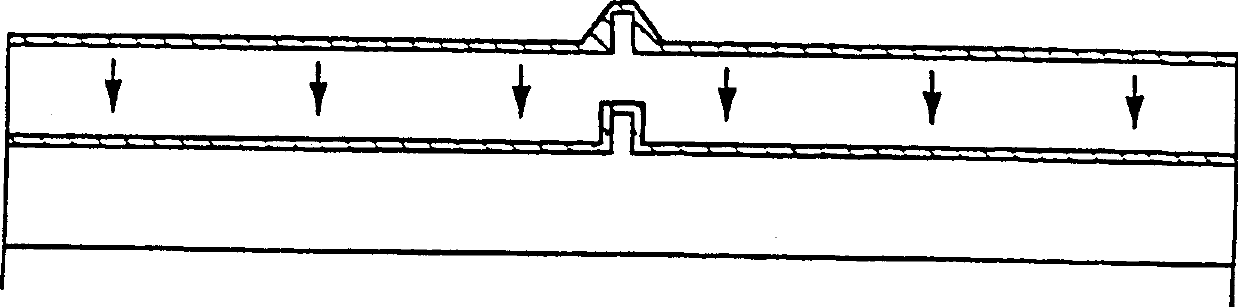

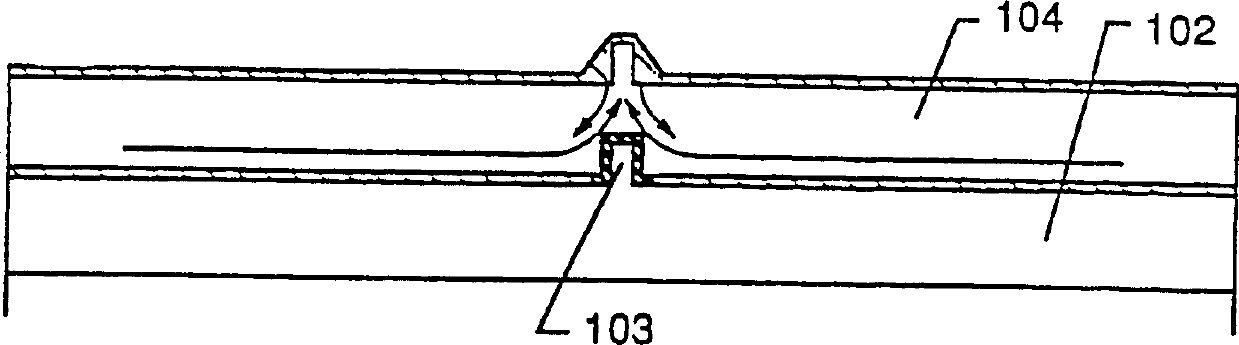

[0108] This embodiment describes the formation process of the monodomain region, which is the most important idea of the present invention. 1(A)-1(F) are cross-sectional views of silicon formed on a substrate having an insulating surface.

[0109] Referring to FIG. 1(A), a silicon oxide film 102 is formed on a glass substrate 101 by sputtering. A quartz substrate or a silicon substrate may also be used instead of the glass substrate. Artificial quartz targets are used in sputtering. The surface of the silicon oxide film 102 formed using the artificial quartz target is extremely flat and smooth. More specifically, for example, the surface roughness has a height in the range of 30 Å and a width of 100 Å or more. Even with AFM (atomic force microscope) observation, it is difficult to find irregularities.

[0110] After the silicon oxide film 102 is formed, patterning is performed to form the uneven pattern 103 intentionally. In this embodiment, a micro-island-like square p...

Embodiment 2

[0159] This embodiment is similar to that described in Embodiment 1, except that the laser irradiation is replaced by strong light with the same energy as the laser. The known RTA (Rapid Thermal Annealing) technique is used in this embodiment.

[0160] RTA is a method of irradiating a workpiece with strong light such as infrared light or ultraviolet light generated by a lamp or the like. This method is characterized in that it can complete the treatment in a short time of about several to tens of seconds, and can heat and cool at a high speed. In this way, only the film on the outermost surface can be heated. More specifically, for example, only a thin film on the surface of a glass substrate can be annealed at an extremely high temperature of about 1000°C.

[0161] Using this method, the processing time is short, and the output can be greatly improved during production. Therefore, this method is very effective for improving productivity.

Embodiment 3

[0163] This embodiment is an example of an active layer of a thin film transistor formed using the monodomain region obtained in the process steps described in Embodiment 1. Although a top-gate structure is described in this embodiment, it can also be used in a bottom-gate structure.

[0164] Referring to FIG. 4(A), according to the process steps described in Embodiment 1, a thin film transistor including a single domain region is formed and patterned. An active layer 403 consisting of only monodomain regions is formed. Also, as described in Embodiment 1, reference numeral 401 denotes a glass substrate, and reference numeral 402 denotes a silicon oxide film.

[0165] Then, a silicon oxide film 404 serving as a gate insulating film was formed to a thickness of 1500 Å by plasma CVD. A silicon oxynitride film or a silicon nitride film may also be used instead of the silicon oxide film.

[0166] Thereafter, an aluminum film 405 was formed to a thickness of 5000 Å by sputtering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com