Process for producing polyimide

A technology of polyimide and aromatic diamine, applied in the field of a method for preparing polyimide, which can solve the problems of molding processability, sliding property, low water absorption, electrical performance, thermal oxidation stability, and radiation protection sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation method of polyimide among the present invention comprises in a solvent that contains 50-100% weight by the compound shown in chemical formula (1) and the equimolar component that is formed by the phenol shown in chemical formula (2) The (amid)imidation reaction proceeds efficiently. Among them, it is preferable to use this method to prepare polyimide having repeating structural units as shown in chemical formula (3).

[0068] The preparation method of the polyimide of the present invention will be illustrated in detail below.

[0069] The process includes dissolving or dispersing diamine, tetracarboxylic dianhydride and end-capping agent in a nitrogen-containing heterocyclic compound represented by chemical formula (1) and phenolic compound represented by chemical formula (2) containing 50-100% by weight. In a solvent of equimolar components, the reaction system is heated to dissolve the monomer and / or polyimide precursor (polyamic acid) in the solvent ...

Embodiment

[0205] The present invention will be described in more detail below using examples. However, the present invention is by no means limited to these examples.

[0206] In addition, methods for testing various samples commonly used in Examples and Comparative Examples will be described below.

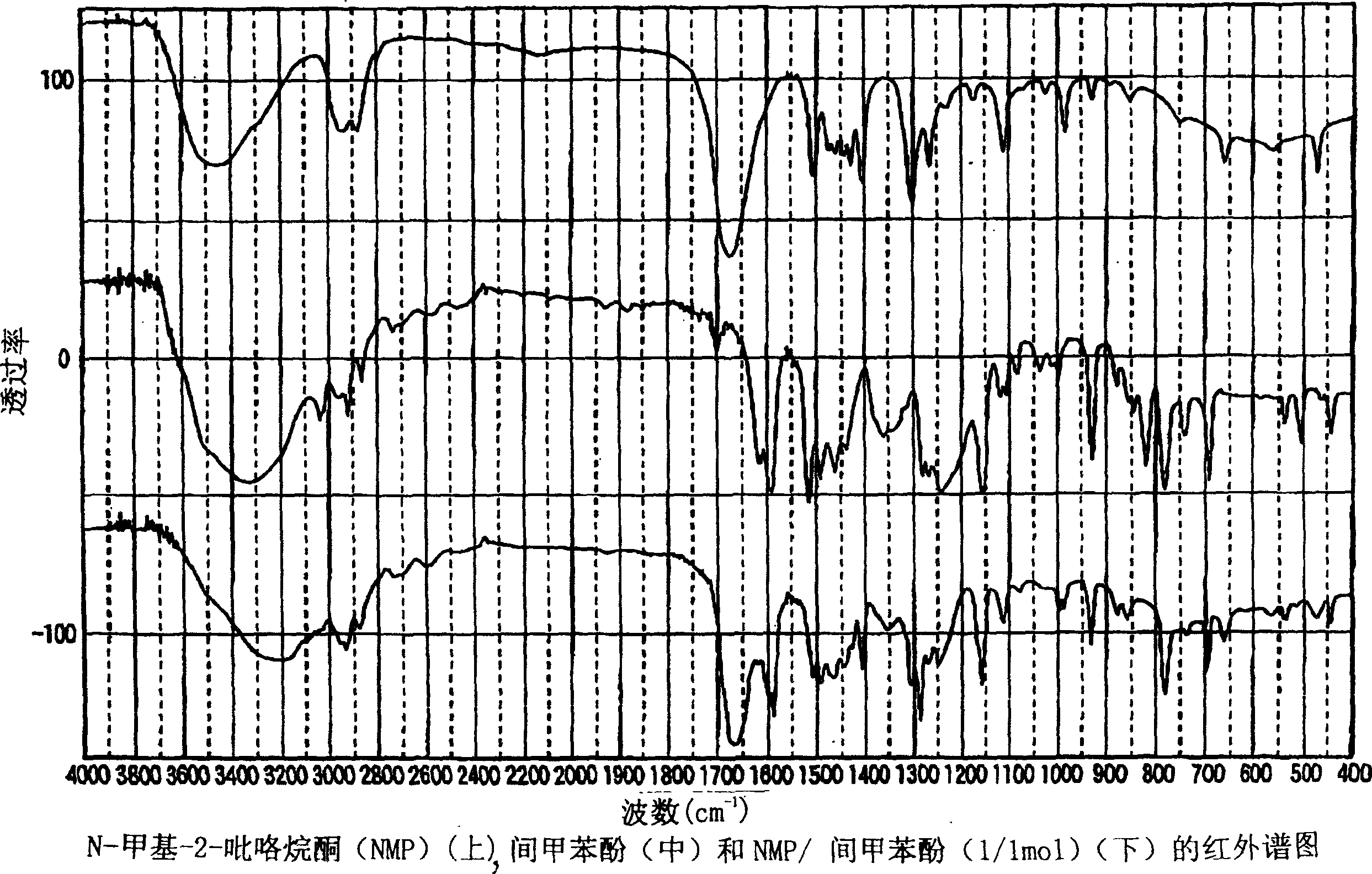

[0207] 1) IR Spectrum of Molar Composition

[0208] Tests were performed using the liquid membrane method on a Bio-Rad FTS-165.

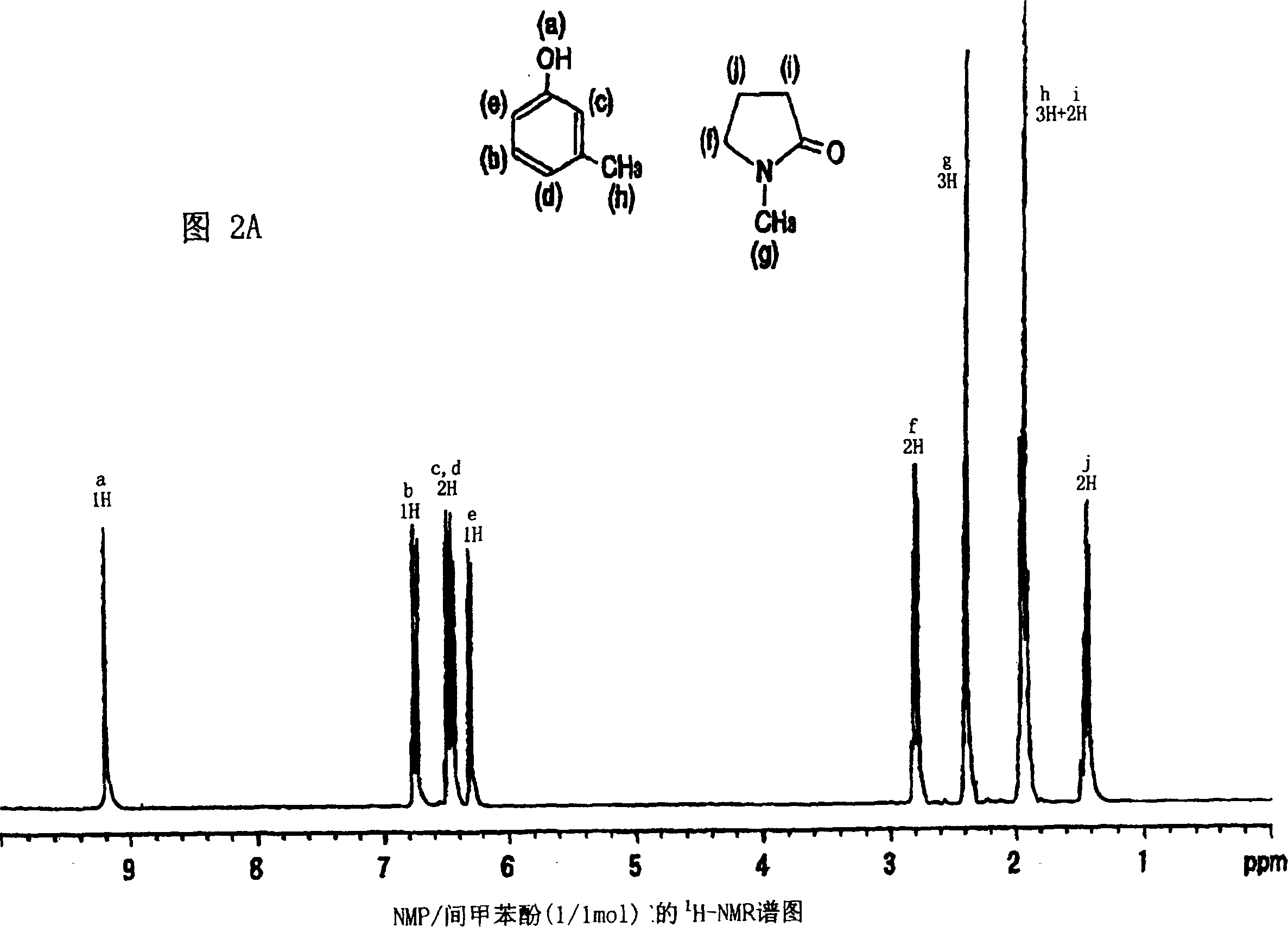

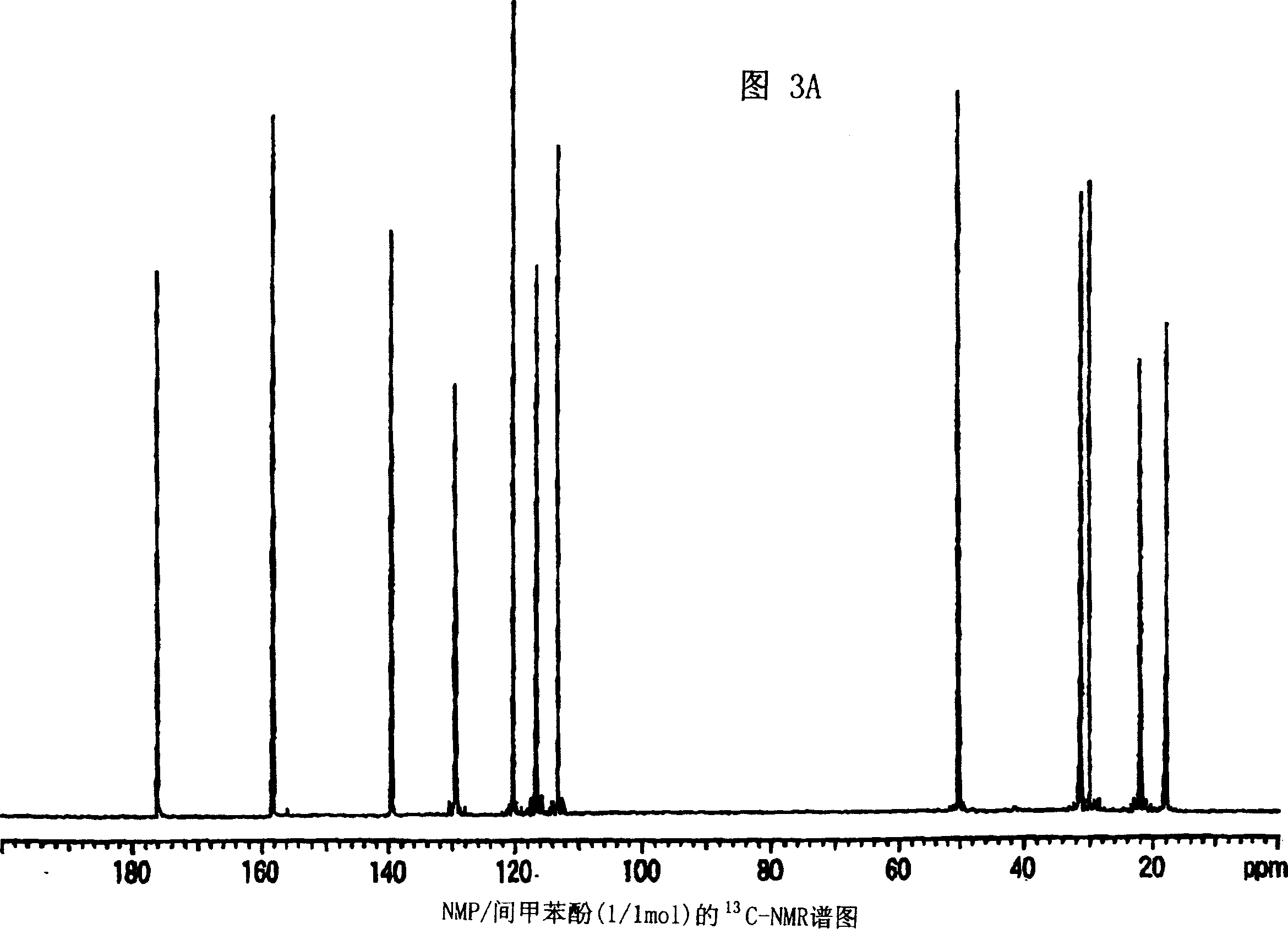

[0209] 2) NMR spectrum of equimolar composition

[0210] Liquid compositions were tested directly on a Varian Unity Inova 400.

[0211] 3) The relative permittivity (ε') and dielectric loss tangent (tanδ) of the equimolar composition were tested using an inductance-capacitance-resistance (LCR) meter bridge measurement method, using an accurate LCR meter HP4284A (Agilent Technologies, Inc.) and LE-22 electrode (Ando Electric Co., Ltd.). The test frequency is 1MHz, and the test condition is 22±1℃ / 60±2%RH.

[0212] 4) Intrinsic viscosity of polyimide powder ...

Embodiment A1

[0221] By adding N-methyl-2-pyrrolidone into a flask with a well-dried packed column, and then carrying out atmospheric distillation in nitrogen to obtain refined N-methyl-2-pyrrolidone, which has a boiling point of 204.5°C and contains The amount of water is 10ppm or less. Further, m-cresol (reagent grade) was similarly distilled to obtain refined m-cresol having a boiling point of 202.2° C. and a water content of 10 ppm or less.

[0222] In a desiccator, pour 99.1g (1.00mol) of the aforementioned refined N-methyl-2-pyrrolidone into the flask, then gradually add 108.1g (1.00mol) of refined m-cresol to it under stirring to obtain Equimolar composition (liquid) of purified N-methyl-2-pyrrolidone and purified m-cresol.

[0223] The equimolar composition thus obtained was heated under normal pressure. At the boil, both the liquid and vapor phase temperatures of the composition were measured to be 230°C. This temperature is 25.5°C higher than the boiling point of refined N-meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com