Method for increasing internal surface wearability of engine cylinder body and cylinder sleeve

An engine block and inner surface technology, applied in engine components, cylinders, mechanical equipment, etc., can solve the problems of shallow hardened layer, limited surface wear resistance, limited wear resistance, etc., to reduce the friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

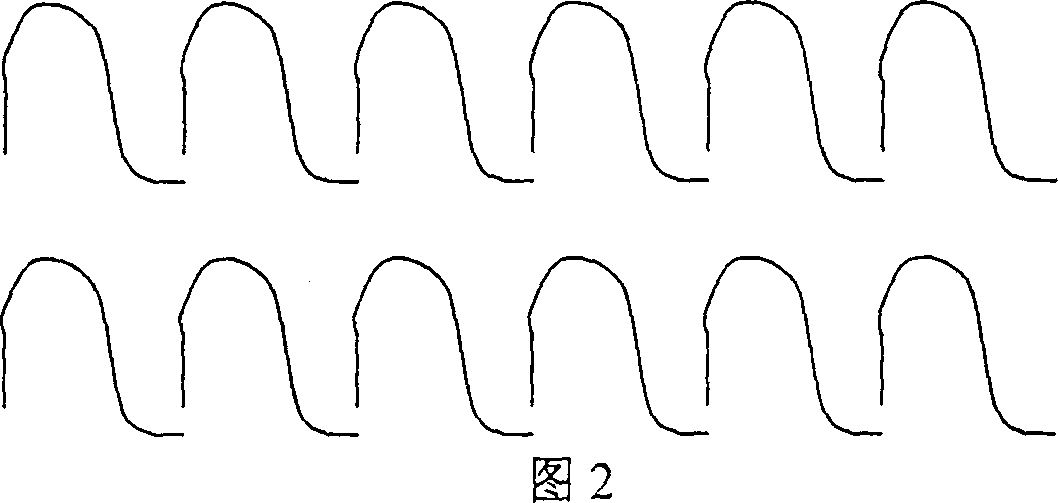

[0023] The engine cylinder block or cylinder liner is made of gray cast iron. After the conventional casting process and machining (including boring, honing inner hole and other processes), the inner diameter of the cylinder block or cylinder liner is about 100 microns away from the final product size. . Blacken the inner wall of the cylinder block or cylinder liner to improve the laser absorption rate on the surface of the material. Then, using CO 2The laser processing machine performs laser quenching on the inner wall of the cylinder block or cylinder liner. The process parameters of laser quenching are: laser power 1.5kw, spot diameter 4mm, scanning speed 45mm / s, laser quenching adopts cross network distribution. The laser quenching area is: when the cylinder body or cylinder liner moves, it includes the stroke area from the top dead center to the bottom dead center of the piston. After laser quenching, the quenched cylinder liner is honed, so that the inner diameter of ...

Embodiment 2

[0026] The engine block or cylinder liner is made of alloy cast iron. After the conventional casting process and machining steps, the inner diameter of the cylinder block or cylinder liner is about 100 microns away from the final product size. Blacken the inner wall of the cylinder block or cylinder liner to improve the laser absorption rate on the surface of the material. Then, using CO 2 Laser heat treatment equipment performs laser quenching on the inner wall of the cylinder block or cylinder liner. The process parameters of laser quenching are: laser power 1.5kw, spot diameter 4mm, scanning speed 45mm / s, laser quenching method is spiral pattern. The laser quenching area is: when the cylinder body or cylinder liner moves, it includes the stroke area from the top dead center to the bottom dead center of the piston. After laser quenching, the quenched cylinder liner is honed, so that the inner diameter of the honed cylinder block or cylinder liner is 10-20 microns smaller ...

Embodiment 3

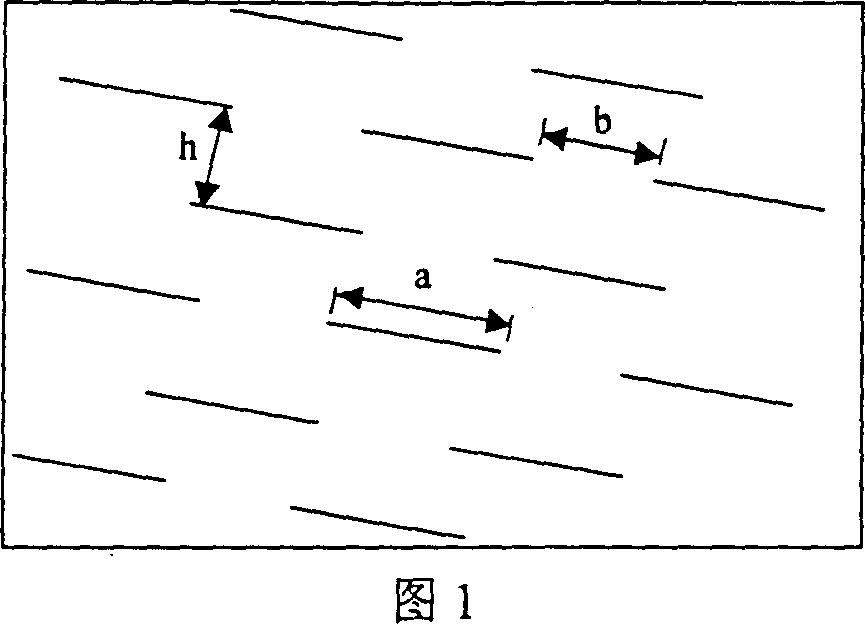

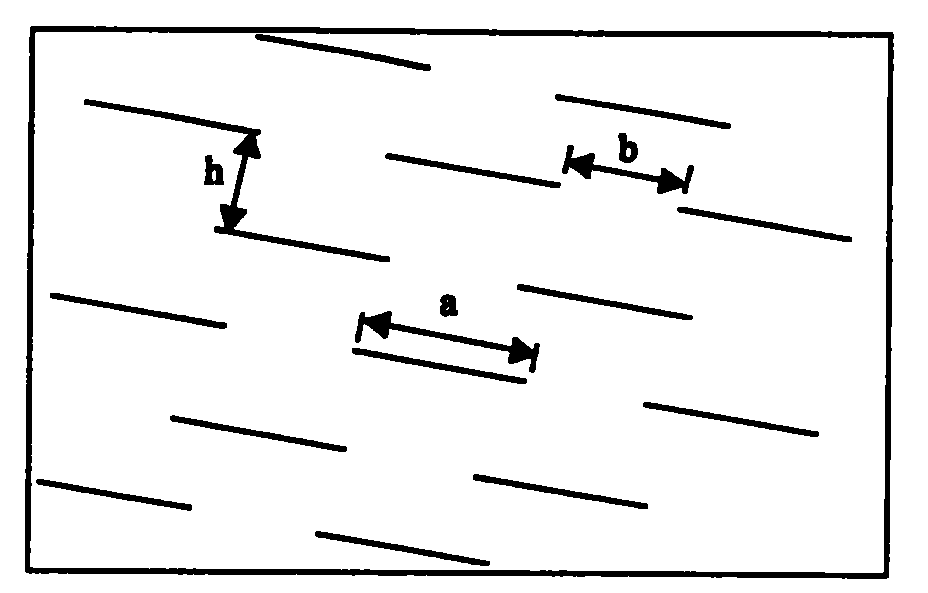

[0029] The material, processing method and process of the alloy cast iron are the same as those in Example 2. Laser quenching process parameters and methods are also the same as in Example 2. After laser quenching, the quenched cylinder liner is honed, so that the inner diameter of the honed cylinder block or cylinder liner is 10-20 microns smaller than that of the finished product. Laser etching is then performed. The arc length a of the laser-etched helical intermittent stripes is 20mm, the distance b between adjacent stripes is 10mm, the pitch h of the helix is 2mm, and the etching depth is 0.08mm. After laser etching, the inner wall of the cylinder block or cylinder liner is finely ground to the size of the finished cylinder liner or cylinder liner with a honing machine, and then it can be used as a finished machine.

[0030] Bench test use effect: If the wear resistance (or service life) of the alloy cast iron cylinder liner without any treatment is taken as a unit, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com