Dechlorination agent and its preparation process

A dechlorinating agent, polyhexenol technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of numerous preparation steps of dechlorinating agent, affecting performance, accelerating pulverization, etc., to achieve good adsorption. and ion exchange performance, improving thermal stability, and accelerating chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the dechlorination agent is to mix polyhexenol, layered bentonite mineral and cetyltrimethylammonium bromide with sodium hydroxide, magnesium hydroxide and copper hydroxide at a temperature of 40 to 80°C. Mix alkali solution to carry out slurry synthesis reaction; after fully reacting, extrude the reaction product, dry at 80-100°C for 4 hours, and then roast at 650°C for 10 hours to obtain the dechlorination agent.

[0015] Performance Testing:

[0016] MgCl in dechlorination reaction product 2 , CuCl 2 and NaCl, MgCl 2 The melting point is the lowest (being 974K), therefore, when the temperature exceeds 974K, MgO, one of the active components of the dechlorination agent, will lose its effect, which will affect the dechlorination performance of the dechlorination agent. Therefore, the highest use of the dechlorination agent of the present invention The temperature should be less than 974K. The test conditions for dechlorination performance ...

Embodiment 1

[0018] Composition formula of dechlorination agent:

[0019] Bentonite 50wt%, chemical reagent polyhexenol 5wt%, cetyltrimethylammonium bromide 5wt%, Mg(OH) 2 (20wt%), Cu(OH) 2 (8 wt%), NaOH (12 wt%).

[0020] Performance Testing:

[0021] The bulk density is 0.76g.ml 1 , the lateral compressive strength is 103N / cm, and the specific surface area of BET test is 93.356m 2 / g.

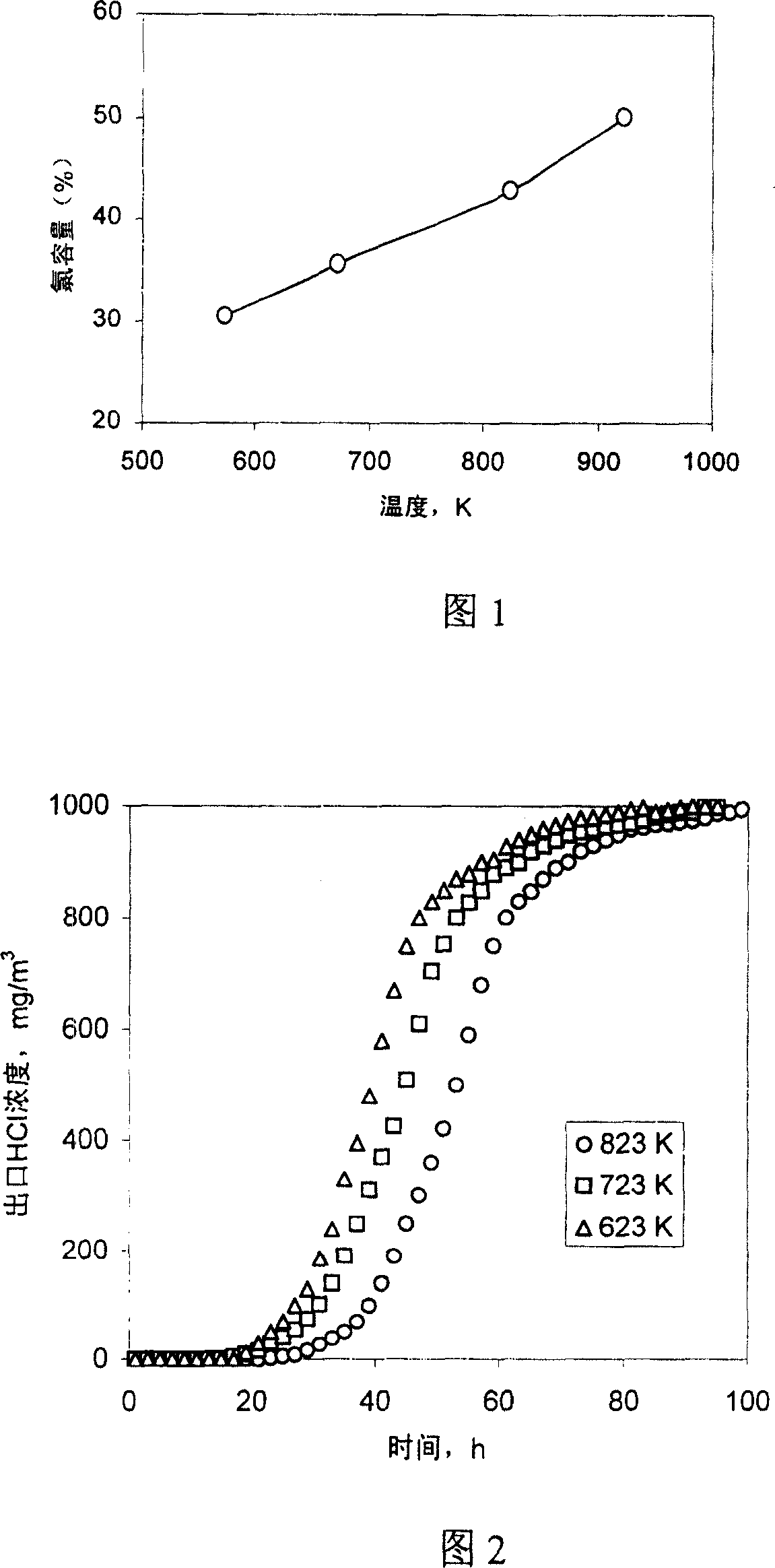

[0022] The relationship between temperature and chlorine capacity is shown in Figure 1, and the breakthrough curve is shown in Figure 2.

Embodiment 2

[0024] Composition formula of dechlorination agent:

[0025] Bentonite 55wt%, chemical reagent polyhexenol 5wt%, cetyltrimethylammonium bromide 5wt%, Mg(OH) 2 (15wt%), Cu(OH) 2 (5wt%), NaOH (15wt%).

[0026] Performance Testing:

[0027] The bulk density is 0.70g.ml 1 , the lateral compressive strength is 95N / cm, and the specific surface area of BET test is 98.267m 2 / g.

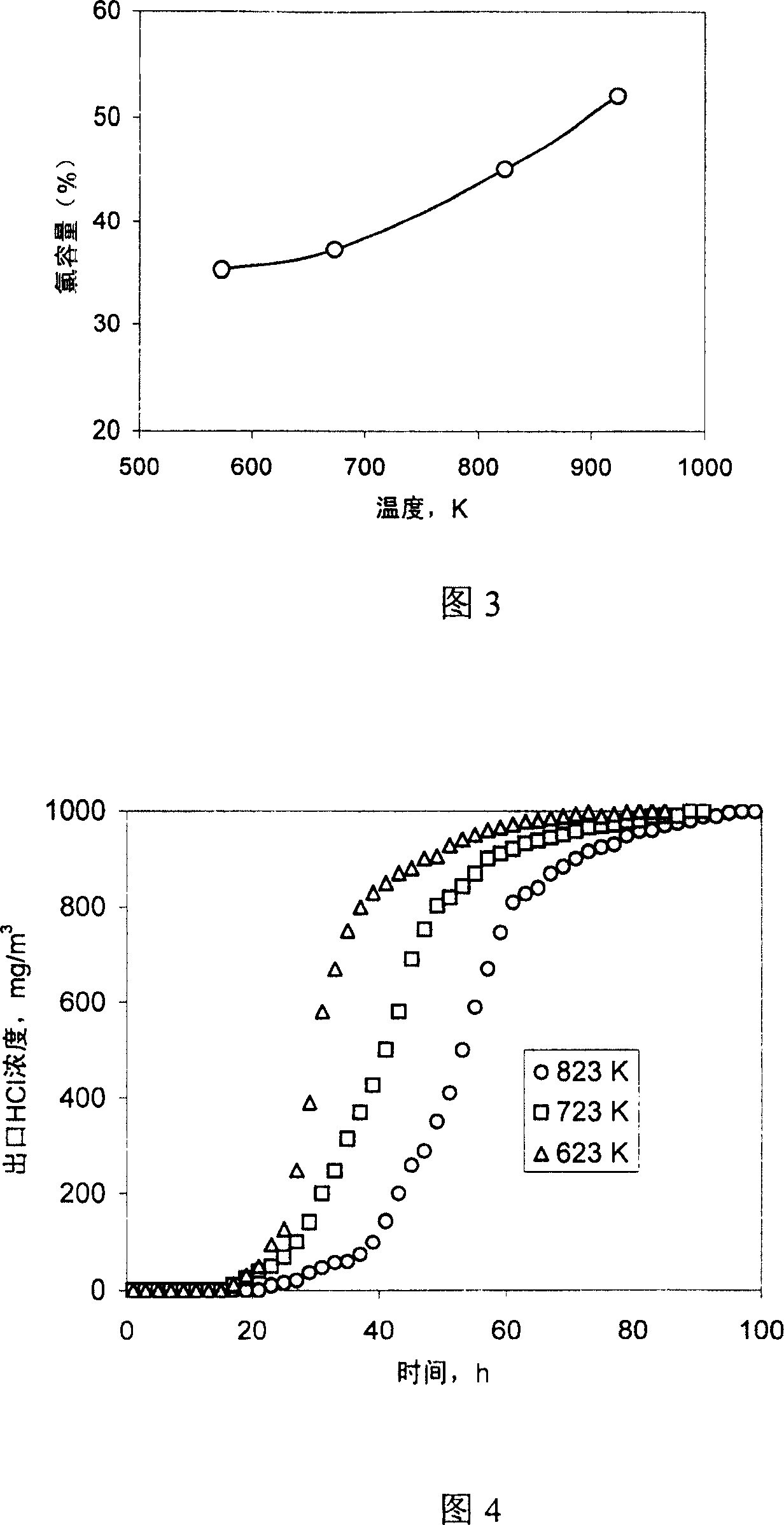

[0028] The relationship between temperature and chlorine capacity is shown in Figure 3, and the breakthrough curve is shown in Figure 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Lateral compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com