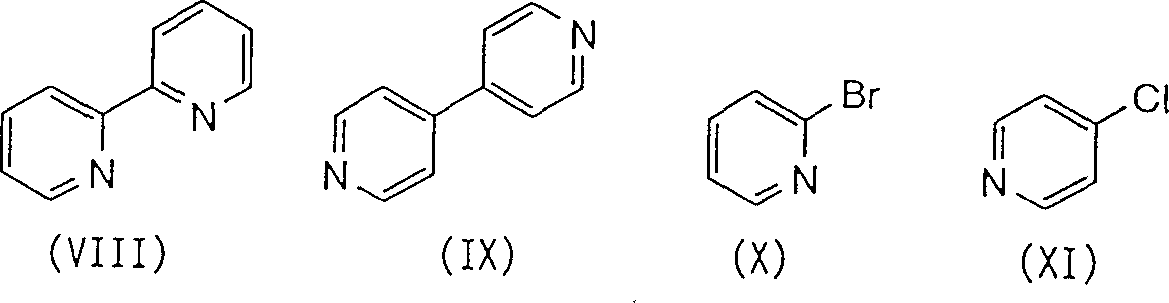

Process for production of 2-pyridylpyridine derivatives

A pyridylpyridine and a technology for a process method are applied in the technical field of producing 2-pyridylpyridine derivatives, and can solve problems such as generation of by-products, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 4.06 g (0.030 mol) of 4-methyl-2-acetylpyridine and 3.56 g (0.032 mol) of 2-methyl-3-dimethylaminoacrolein in 40 ml of tetrahydrofuran, and add to it 3.63 g (0.032 mol) of potassium tert-butoxide were added and heated at 60° C. for 30 minutes. 23.12 g (0.30 mol) of ammonium acetate and 30 ml of acetic acid were added to the mixed solution, and after making it react at 60° C. for 2 hours, the internal temperature was raised to 105° C. to remove tetrahydrofuran, which was then allowed to react at 105° C. for 2 hours. Hours, after the reaction solution was cooled, 80 ml of 25% NaOH aqueous solution was added thereto, followed by extraction with 4×100 ml of ethyl acetate. The organic layer was dried over anhydrous sodium sulfate, filtered, and concentrated. Toluene was added to the concentrate for recrystallization, whereby 3.30 g (yield: 59.7%) of a pale yellow powder was obtained. HPLC analysis (column: ODS-80TM; Detection UV: 254nm; Flow rate: 1.0ml / min; Eluen...

Embodiment 2

[0034] 5.14 grams (0.030 moles) of 3-acetyl quinoline and 3.12 grams (0.031 moles) of 3-dimethylaminoacrolein were dissolved in 35 milliliters of tetrahydrofuran, and 3.64 grams (0.032 moles) and tert-butyl potassium alkoxide and heated at 60°C for 10 minutes. Subsequently, 18.50 g (0.24 mol) of ammonium acetate and 14 ml of acetic acid were added, and after reacting at 60°C for 2 hours, the internal temperature was raised to 105°C to remove tetrahydrofuran, followed by reacting at 105°C for 2 hours. After the reaction solution was cooled, 60 mL of 25% aqueous NaOH was added, and the mixture was extracted with 4×100 mL of ethyl acetate. The organic layer was dried over anhydrous sodium sulfate, filtered, and concentrated. The concentrate was distilled under reduced pressure (bp. 165-170° C. / 0.1 Torr) to obtain 2.88 g (yield: 56.0%) of a pale yellow liquid. HPLC analysis (column: ODS-80TM; Detection UV: 264nm; Flow rate: 1.0ml / min; Eluent: acetonitrile / water=82 / 18; Buffer: tr...

Embodiment 3

[0035] Dissolve 2.91 g (0.024 mol) of 4-acetylpyridine and 2.97 g (0.030 mol) of 3-dimethylaminoacrolein in 100 ml of THF, add 2.69 g (0.024 mol) and potassium tert-butoxide, and Heat at 60°C for 10 minutes. Subsequently, 23.12 g (0.30 mol) of ammonium acetate and 60 ml of acetic acid were added, and after reacting at 60° C. for 3.5 hours, THF was removed in an evaporator. Then 100 mL of water and 150 mL of 25% aqueous NaOH were added, and the mixture was extracted with 4 x 100 mL of ethyl acetate. The organic layer was dried over anhydrous sodium sulfate, concentrated under reduced pressure, and recrystallized from hexane to obtain 1.92 g (yield: 51.2%) of colorless flaky crystals. HPLC analysis (column: ODS-80TM; Detection UV: 264nm; Flow rate: 1.0ml / min; Eluent: acetonitrile / water=50 / 50; Buffer: triethylamine 0.1%, acetic acid 0.1%) shows, The purity of the product is 99.3%, and the melting point is 55.8°C-56.0°C. Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com