Yeast recombinant strain and IFN alpha-2b interferon purifying method

A purification method and interferon technology are applied in the purification field of yeast recombinant strains and IFNα-2b interferon, which can solve the problems of large side effects, low specific activity and high production cost, and achieve cost reduction, shortening purification time and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

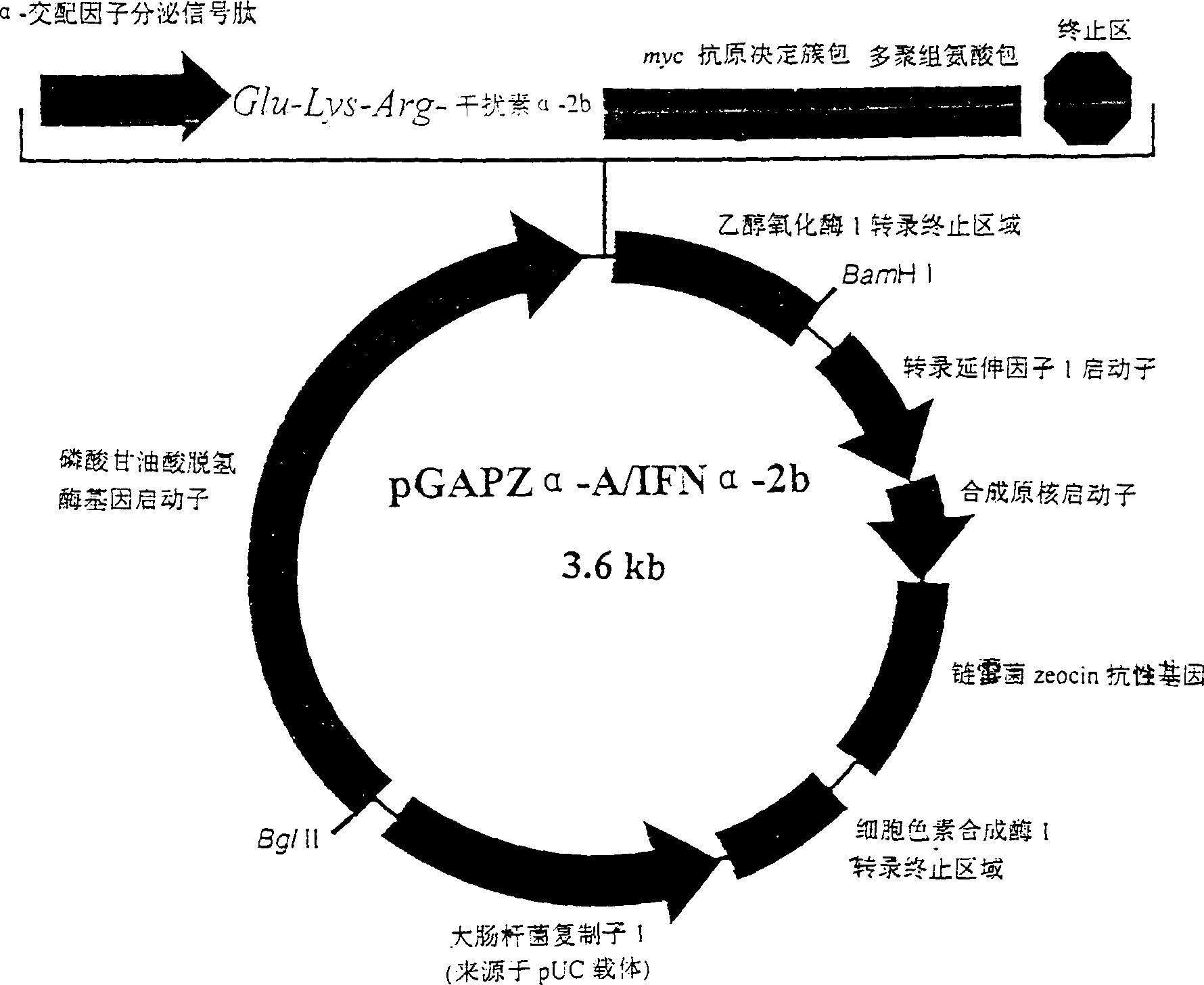

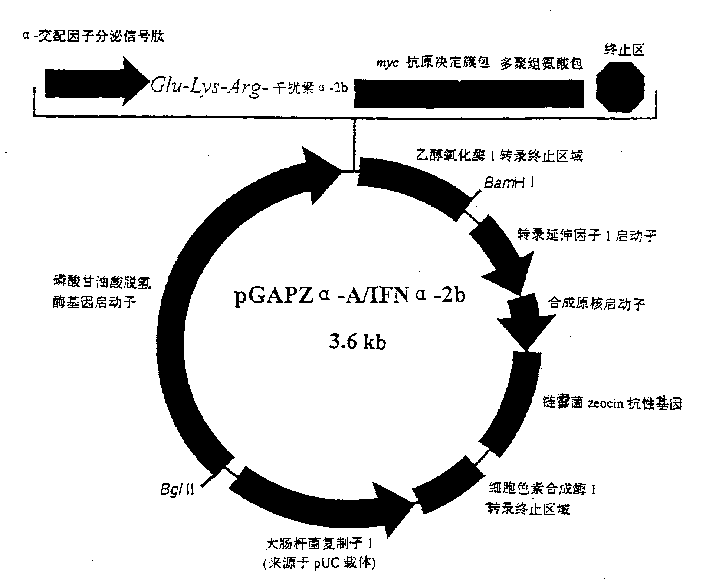

[0027] 1. Construction of IFNα-2b interferon yeast engineering bacteria

[0028] (1) Materials:

[0029] 1. IFNα-2b gene

[0030] 2. pGAPZα-A, P.pastoris Strain GS115 (his4) were purchased from Australia

[0031] Invitrogen Corporation.

[0032] (2) Method:

[0033] 1. Gene PCR amplification:

[0034] (1) Primer design: After deleting the Kex2 (Lys-Arg) site in the 5' end primer

[0035] Ste13 site (Glu-Ala-Glu-Ala) and initiation codon ATG.

[0036] P1-5'G CTCGAG AAAAGA ATG TGTGATCTGCCTCAAACC3'("ATG" is deleted

[0037] remove)

[0038] XhoI Lys-Arg (Kex2 site)

[0039] P2-5'G TCTAGA TCATTCCTTACTTCTTAAACT3'

[0040] wxya

[0041] (2) Thermal cycle: 95°C, 5'; 95°C, 30"→49°C, 30"→72°C, 60"

[0042] 72°C, 10'; 30 cycles of amplification.

[0043] 2. PCR amplification product recovery and cloning:

[0044] (1) The IFNα-2b gene was amplified and electrophoresed to obtain a DNA band of about 521 bp;

[0045] (2) The target fragmen...

Embodiment 2

[0050] Purification method of α-2b interferon: After constructing α-2b interferon yeast engineered bacteria (IFNα-2b / pGAPZα-A / GS115), store the strain at -80°C. Before fermentation, inoculate a plate to activate the strains, inoculate a single colony in YPD+Zeocin100 mg / L medium and ferment for 72 hours, collect the fermentation supernatant by centrifugation, adjust the pH to 4.0-5.0 with acetic acid, and pass through the CM Sepharose column layer Analysis, collect 0.4 mol / L sodium chloride elution peak, add ammonium sulfate to 30%, centrifuge to get supernatant, pass PhenylSepharose column chromatography, collect 10% ammonium sulfate elution peak, pass DEAE Sepharose column chromatography, collect The peak was eluted with 0.1 mol / L sodium chloride, and the protein peak was collected through Sephacryl S-200 column chromatography to obtain a stock solution of α-2b interferon with a purity greater than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com