Construction method of bacillus phosphorus relieving engineering bacterial strain

A technology of engineering strains and bacillus, applied in biochemical equipment and methods, bacteria, treatment of microorganisms with electricity/wave energy, etc., can solve the problems that agricultural and environmental microorganisms are not involved, and achieve large mutation range and mutagenesis efficiency High and enhanced decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

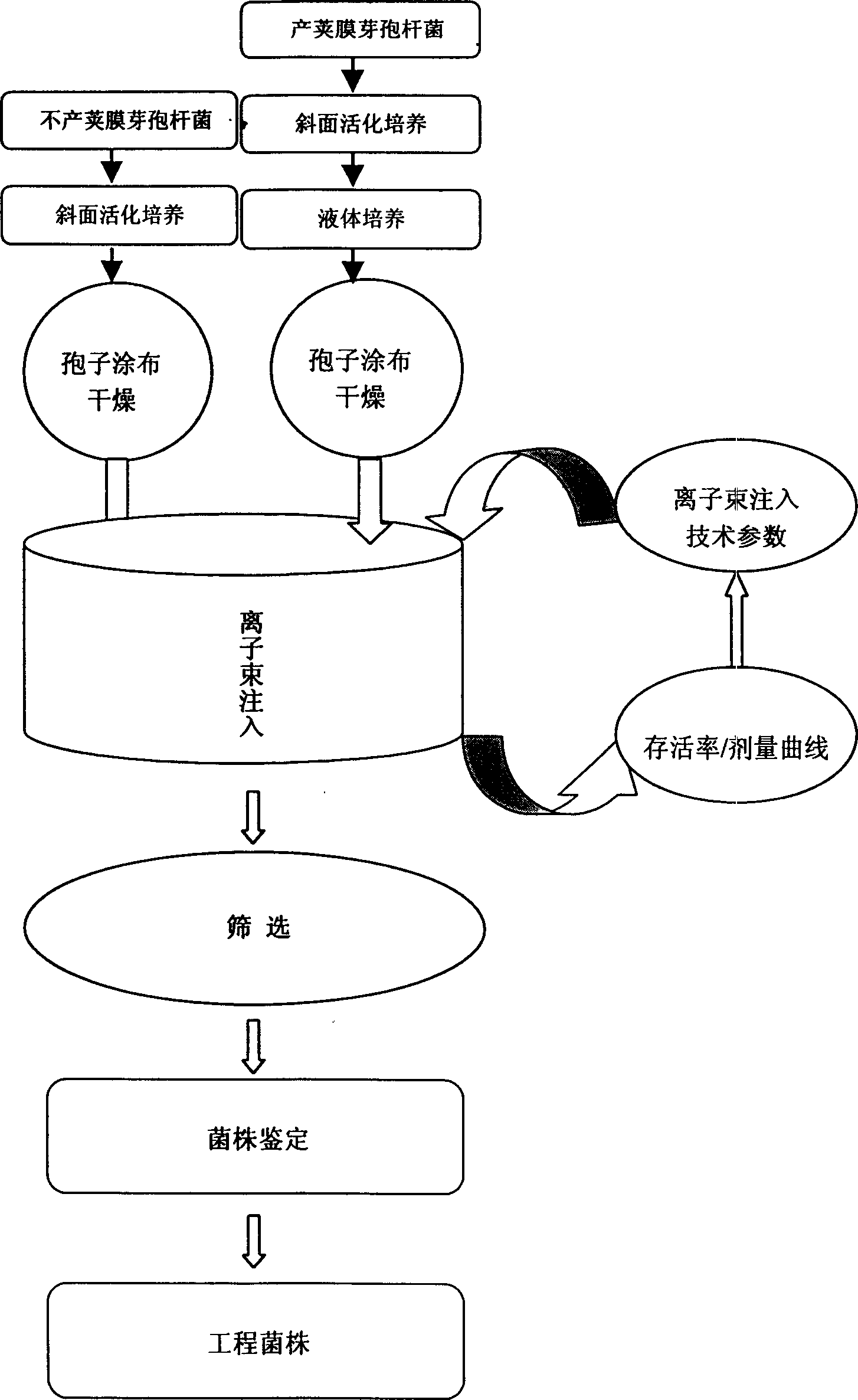

Method used

Image

Examples

Embodiment 1

[0062] Application N + Ion beam implantation induces mutation of Bacillus megaterium to obtain an engineered strain that efficiently decomposes lecithin. Activated Bacillus megaterium on the slant of beef extract peptone medium, cultured at 28-30°C for 36-48 hours, eluted with normal saline, collected spores by centrifugation, diluted and spread on sterile empty dishes, and placed them on a clean bench. Ventilation and drying for 0.5~1h; energy consumption is 15~25KeV, dosage is 40~150×10 14 ions / cm 2 N + In vacuum (vacuum degree is 2 × 10 -2 ~4.2×10 -3 Pa), carry out intermittent pulse injection under sterile conditions; then wash out the spores with physiological saline, after screening on NBRIY (containing lecithin) medium, after identification, an engineering strain that efficiently decomposes lecithin is obtained. The ability to decompose lecithin is increased by 18 to 25%.

Embodiment 2

[0064] Application H + Ion beam implantation induces the mutation of the silicate bacteria KNP414 strain to obtain an engineered strain that efficiently decomposes inorganic phosphorus, inorganic potassium and lecithin.

[0065] KNP414 was activated on nitrogen-free medium, cultured at 28-30 °C for 30-36 h, inoculated into liquid medium without capsular spores, cultured at 28-30 °C, 200-250 rpm for 48-56 h, and the spores were collected by centrifugation , diluted and spread on a sterile empty plate, naturally dried for 0.5-1h; the energy used is 15-25KeV, and the dose is 60-200×10 14 ions / cm 2 H + In vacuum (vacuum degree is 3 × 10 -2 ~5×10 -3 pa), intermittent pulse injection under sterile conditions; then eluted spores with normal saline, screened on NBRIY medium (containing lecithin), and then re-screened on NBRIP medium, after identification, 2 strains were obtained with high efficiency decomposition Engineering strains KNP41401 and KNP41402 for inorganic potassium, ...

Embodiment 3

[0067] Apply He + Ion beam implantation induces mutation of Bacillus subtilis to obtain an engineered strain that efficiently decomposes phytate phosphorus. Activated Bacillus subtilis on the slant of beef extract peptone medium, cultured at 28-30°C for 36-48 hours, eluted with phosphate buffer, collected spores by centrifugation, diluted and spread on sterile glass slides, clean bench Ventilation and drying for 0.5~1h; the energy used is 10~20KeV, and the dosage is 40~150×10 14 ions / cm 2 He + In vacuum (vacuum degree is 2 × 10 -2 ~5×10 -3 pa), intermittent pulse injection under sterile conditions; then eluted spores with phosphate buffer, screened on NBRIY (phytate phosphorus) medium, and after identification, an engineering strain that efficiently decomposes phytate phosphorus was obtained. The ability to decompose phytate phosphorus is increased by 25 to 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com