Prepn of ferromagnetic semiconductor with graded components

A magnetic semiconductor and semiconductor technology, applied in semiconductor/solid-state device manufacturing, inductor/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve the problems of large strain and poor stability of heterogeneous structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The composition graded ferromagnetic semiconductor preparation method of the present invention, its step comprises:

[0018] Step 1: Select a semiconductor single wafer, which is used as a base material, and the base material is: gallium arsenide, gallium antimonide, silicon, indium phosphide, germanium, gallium phosphide;

[0019] Step 2: heating the base material to prepare for the next step process, the heating temperature range is 0-800 degrees;

[0020] Step 3: growing a magnetic semiconductor material with graded composition on the substrate, which is a semiconductor material doped with transition metals or earth metals, such as gallium manganese arsenic, gallium manganese antimony, and manganese silicon;

[0021] Step 4: Carrying out heat treatment on the above-mentioned magnetic semiconductor material, the heat treatment temperature ranges from 100-800 degrees.

[0022] In step 1, one or more layers of buffer layers can be epitaxially grown on the substrate as ...

Embodiment

[0030] (1) Using GaSb single crystal as the substrate;

[0031] (2) Using an ion beam epitaxy system to epitaxially grow Ga with a graded composition on a GaSb substrate 1-x mn x Sb material;

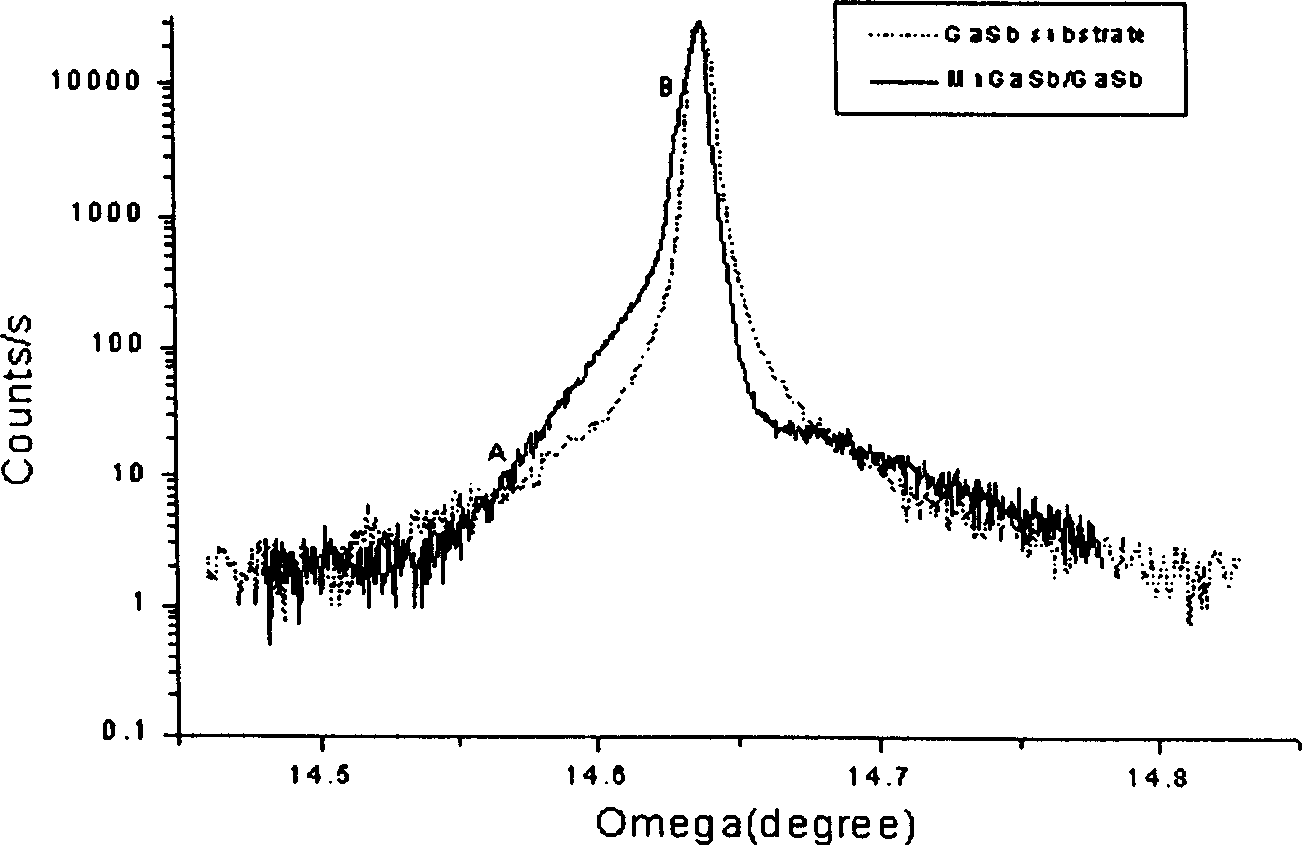

[0032] (3) The samples were tested with the ω-2θ and small-angle diffraction modes of the X-ray diffractometer, and no new diffraction peaks were found in the test results. Ga 1-x mn x The ω-2θ diffraction curve (solid line) of the Sb sample along the (002) direction is shown in figure 1 shown. It can be calculated from the figure that the Mn content x gradually decreases from 0.09 to 0 from the surface to the inside of the crystal, and the corresponding lattice mismatch Δa / a 0 Gradually decrease from 0.005 to 0. Visible, Ga 1-x mn x The Sb sample is a semiconductor with a gradient composition of sphalerite structure;

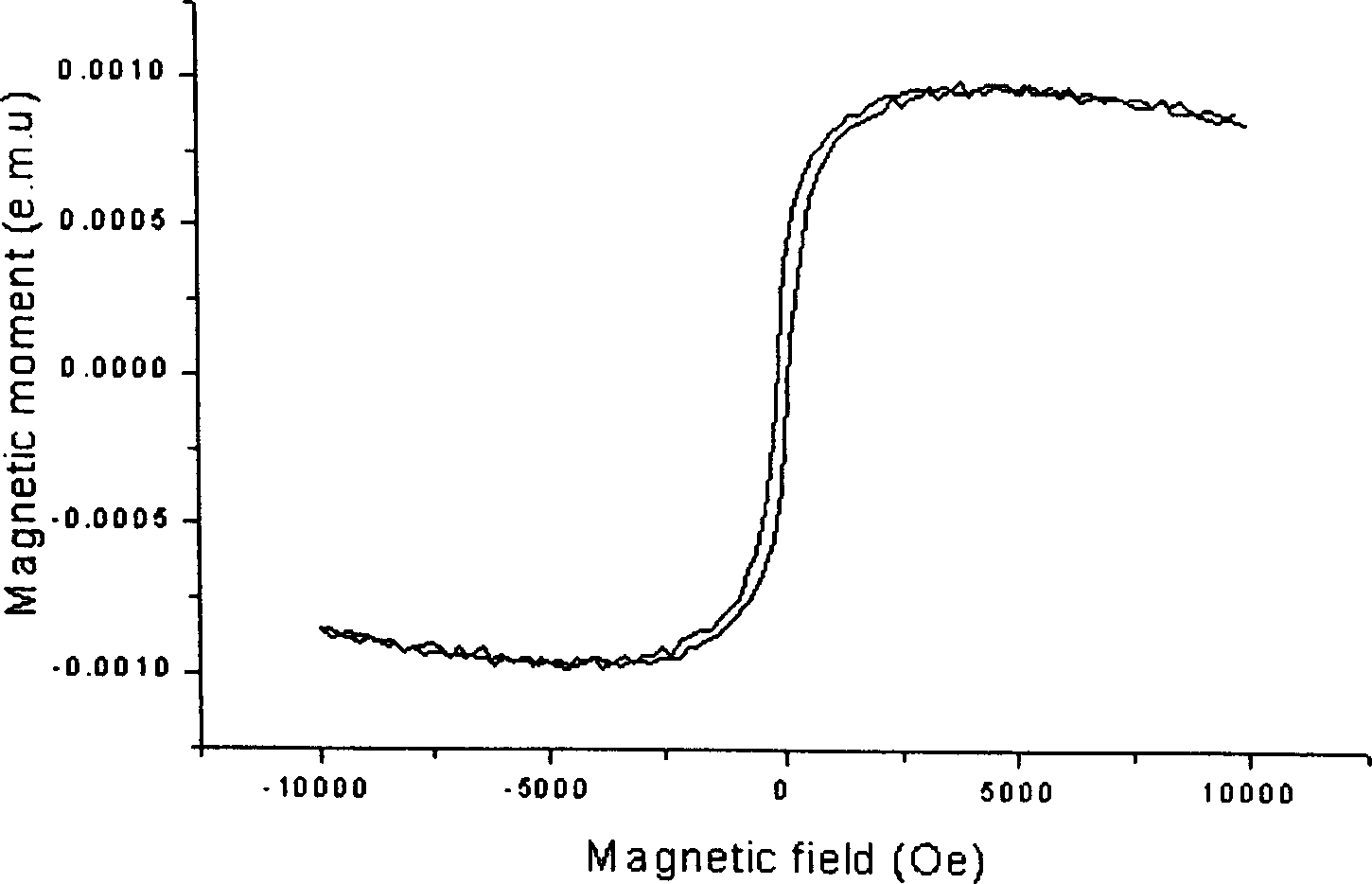

[0033] (4) At room temperature, the hysteresis loop of the above sample was measured with a vibrating sample magnetometer (VSM) LDJ9600 as figure 2 shown. w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com