Catalyst for producing melaphenylene from m-dinitrobenze by liquid phase hydrogenation and preparation thereof

A kind of dinitrobenzene liquid, the technology of making m-phenylenediamine, applied in the direction of amino compound preparation, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of expensive, unseen patent documents Report, environmental pollution and other issues, to achieve low cost, long life, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

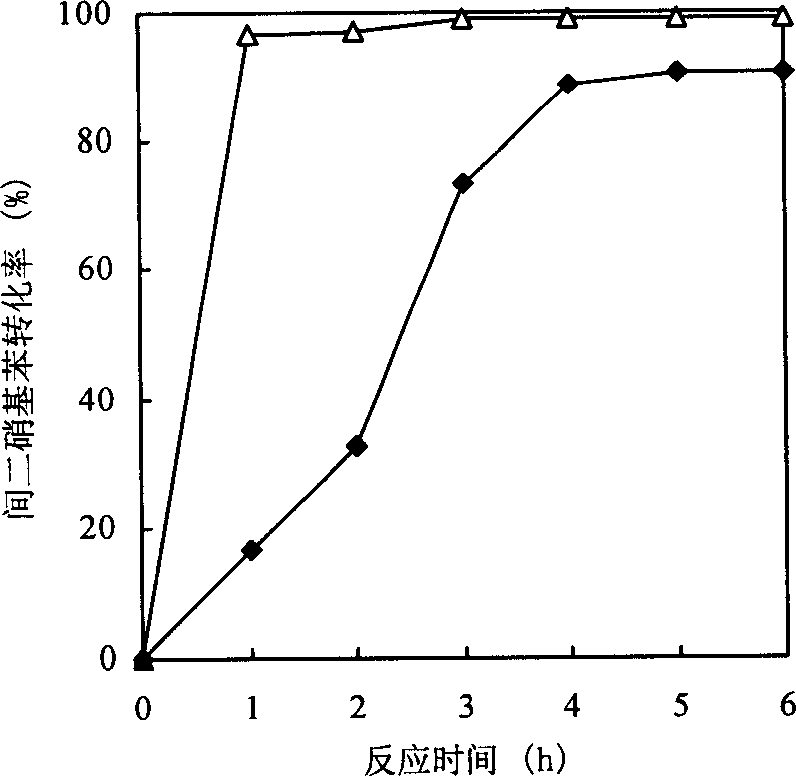

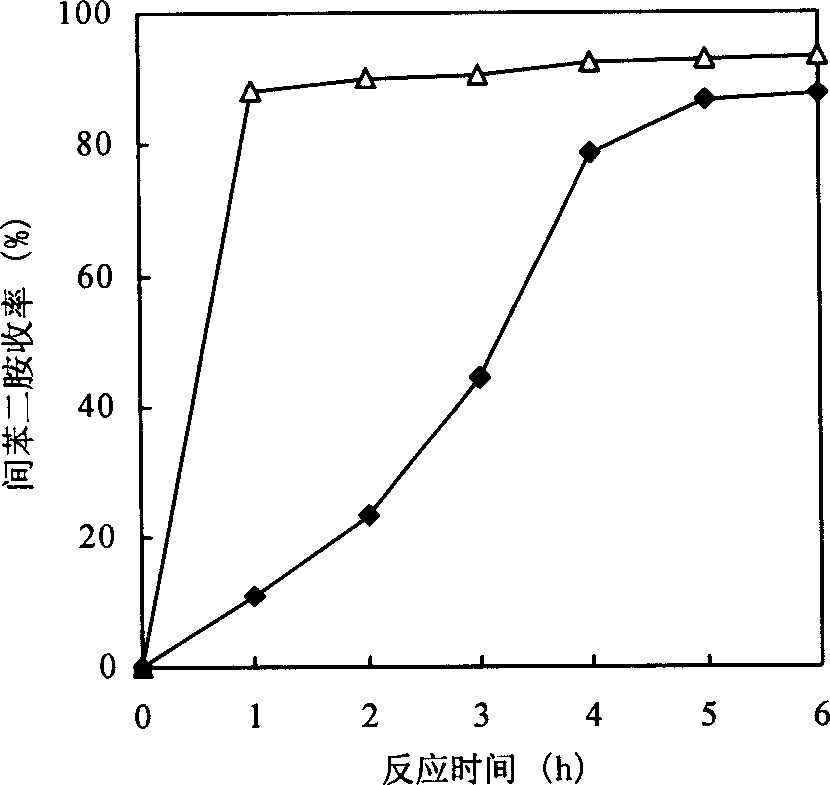

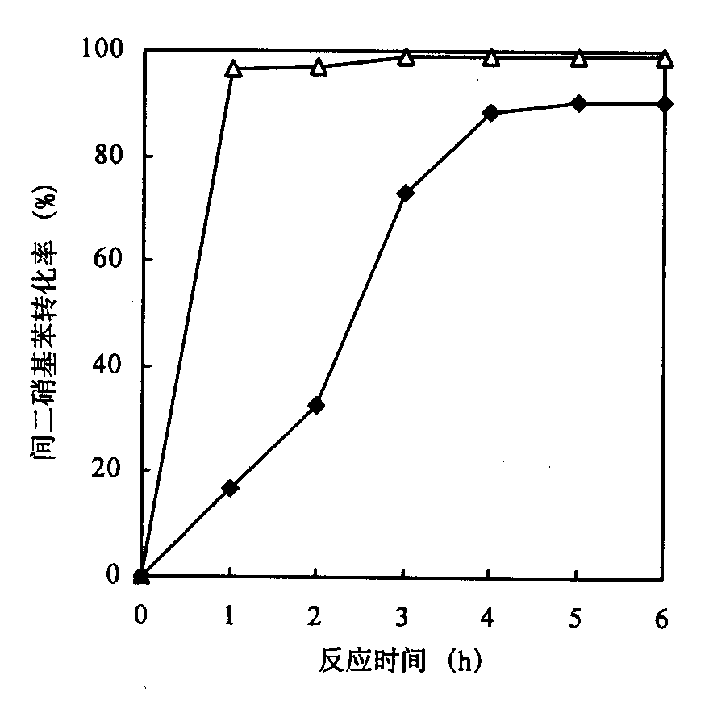

[0014] Example 1: SiO 2 Carrier (specific surface area 432m 2 / g) Roasting at 550°C for 4 hours in advance, measuring its water absorption, using the equal volume impregnation method to impregnate with an aqueous solution of lanthanum nitrate with a content of 5% by weight, immersing at 20°C for 6 hours, and then drying at 110°C, Calcined at 400°C for 5 hours in an air atmosphere, then impregnated with a nickel nitrate aqueous solution with a content of 15% by weight, impregnated at 20°C for 6 hours, then dried at 110°C, and calcined at 400°C for 5 hours in an air atmosphere. Crush the solid particles, and sieve the 80-100 mesh particles. The pre-catalyst was reduced with hydrogen at 400°C for 2 h, and the reduced catalyst was 2 The atmosphere was lowered to room temperature, and protected with nitrogen for later use. The catalyst has excellent m-dinitrobenzene hydrogenation performance, and reacts under the conditions of 100° C., hydrogen pressure of 2.6 Mpa, catalyst dosa...

example 2

[0015] Example 2: Carry out catalyst preparation by the step of example 1, only change the concentration of lanthanum nitrate aqueous solution and be that lanthanum content by weight is 7%, under the constant situation of other conditions, the catalyst prepared is used in m-dinitrobenzene liquid Phase hydrogenation reaction. At the end of the reaction, the conversion rate of dinitrobenzene is higher than 95%, and the yield of m-phenylenediamine is higher than 90%.

example 3

[0016] Example 3: Carry out catalyst preparation by the step of example 1, only change the solution of rare earth element to be cerium nitrate, be 5% by weight, under the situation that other conditions are constant, the catalyst prepared is used in m-dinitrobenzene liquid Phase hydrogenation reaction. At the end of the reaction, the conversion rate of m-dinitrobenzene is higher than 95%, and the yield of m-phenylenediamine is higher than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com