Metal surface anti-corrosion method based on surface nanometer construct

A metal surface, anti-corrosion technology, applied in the direction of metal material coating process, solid-state chemical plating, coating, etc., can solve the problems of easy cracking, corrosion, easy penetration of electrolyte solution, etc., to eliminate cracking phenomenon, The effect of improving hydrophobicity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

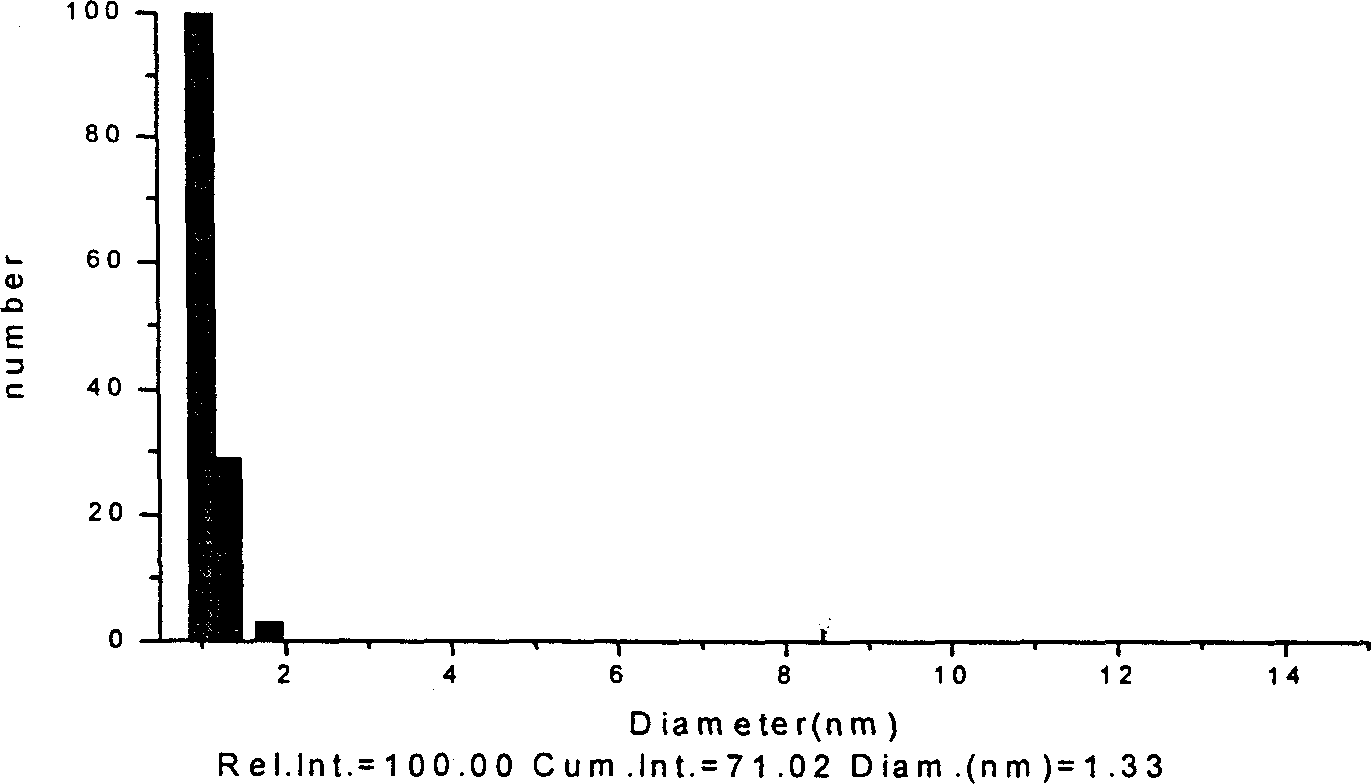

[0017] Preparation of ultrafine TiO 2 Sol: First add 1ml EAcAc to 20ml absolute ethanol under normal temperature and pressure, add 4ml butyl titanate under stirring, react for 1h, add 0.2ml water within 30min, stir for 5 hours, then leave for one day , Get superfine TiO 2 Sol; from figure 1 The distribution map of colloidal particles of the sol shows that TiO 2 The diameter of the colloidal particles is basically 1.00 nm, and there is almost no large agglomeration phenomenon;

[0018] Pre-treatment of the metal substrate surface: Polish 316L stainless steel with 1000-mesh water abrasive paper, polish with No. 10 metallographic sandpaper, and then use acetone, absolute ethanol, ultra-pure water, ultrasonic cleaning, and dry for use;

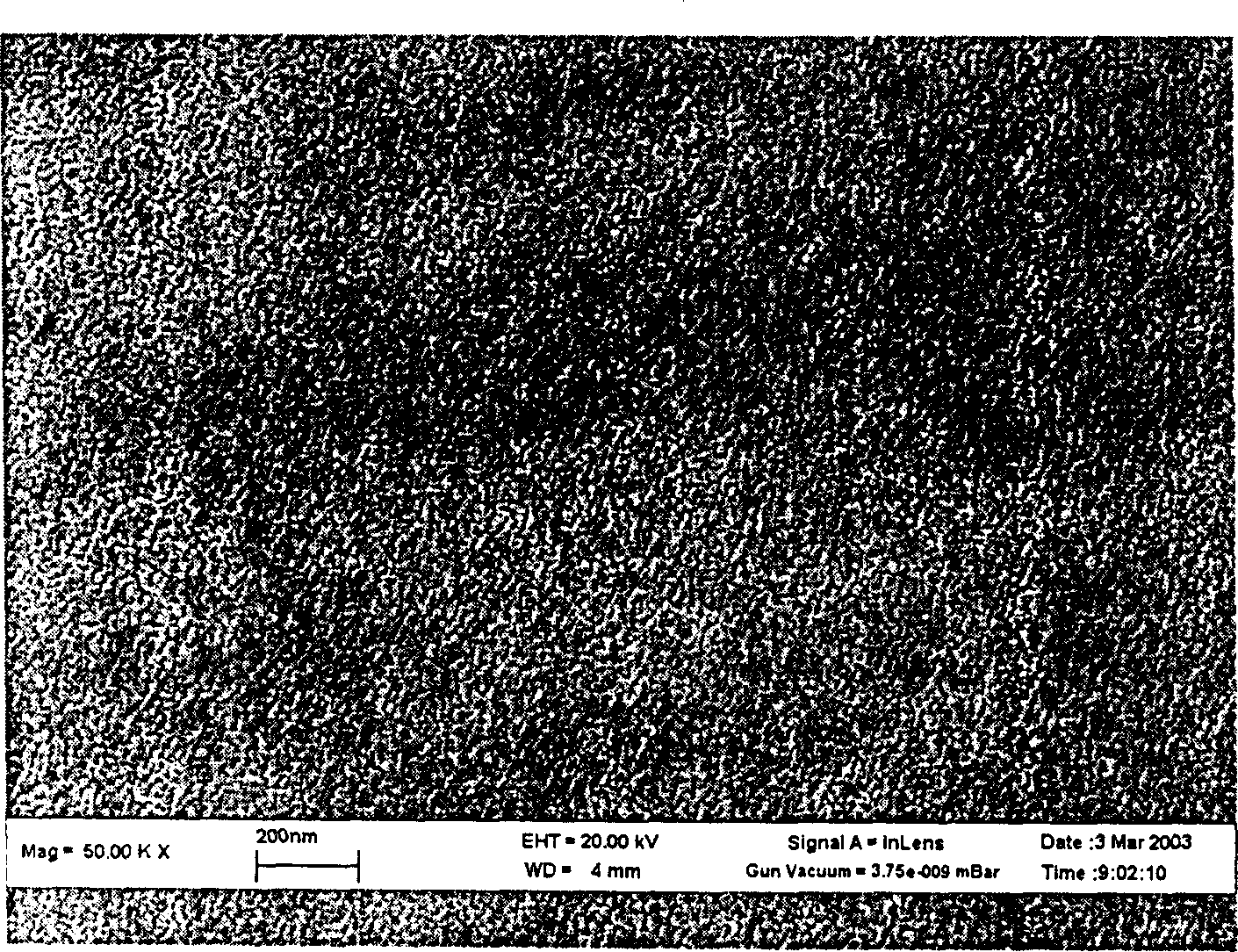

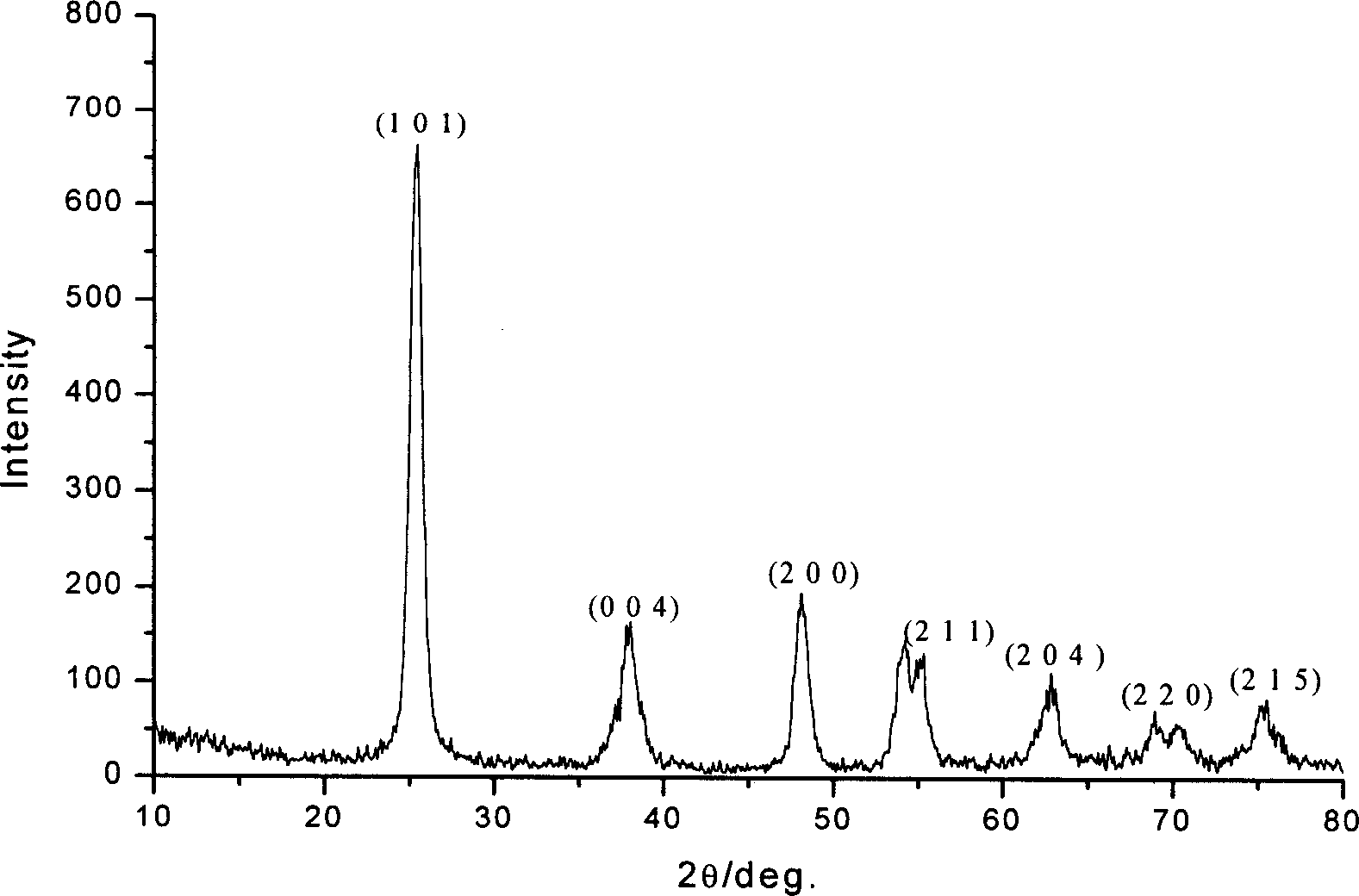

[0019] Coating: Immerse the metal substrate in TiO 2 In the sol, use a mechanical pulling machine to pull at a uniform speed of 1mm / s. After natural drying, repeat the pulling 3 times, put it in a muffle furnace at 450°C for 30 minutes, and cool natu...

Embodiment 2~4

[0024] Nano TiO 2 The preparation of membrane / 316L was the same as in Example 1, only the hydrothermal post-treatment time was changed. The results are shown in Table 1.

[0025] Example

Embodiment 5

[0027] Nano TiO 2 The preparation of membrane / 316L is the same as in Example 1. Nano TiO prepared by 316L stainless steel and sol-gel method 2 Membrane / 316L and hydrophobic nano-TiO 2 Membrane / 316L electrode is used as working electrode, Pt chip electrode is used as auxiliary electrode, reference electrode is saturated calomel electrode (SCE), electrolyte contains Ringer solution, NaCl solution and HCl solution. The electrolytic cell is placed in a shielding box during the whole test China-Israel reduces the external interference to the test system. The electrochemical linear polarization scan range is ±15mV near the corrosion potential, and the scan speed is 0.167mV / s; the frequency measured by the AC impedance method is 10 5 ~10 -3 , The results are shown in Tables 2 to 4. From Table 2 we can see the surface structure of nano-TiO 2 The corrosion resistance of the 316L stainless steel film has been significantly improved, and the hydrophobic nano-TiO 2 The film is more obvious fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com