Method for separating and purifying ephedrine by using weak acid cation exchange resin and macroporous resin

A technology of cation exchange and macroporous resin, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve high efficiency, simple process, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

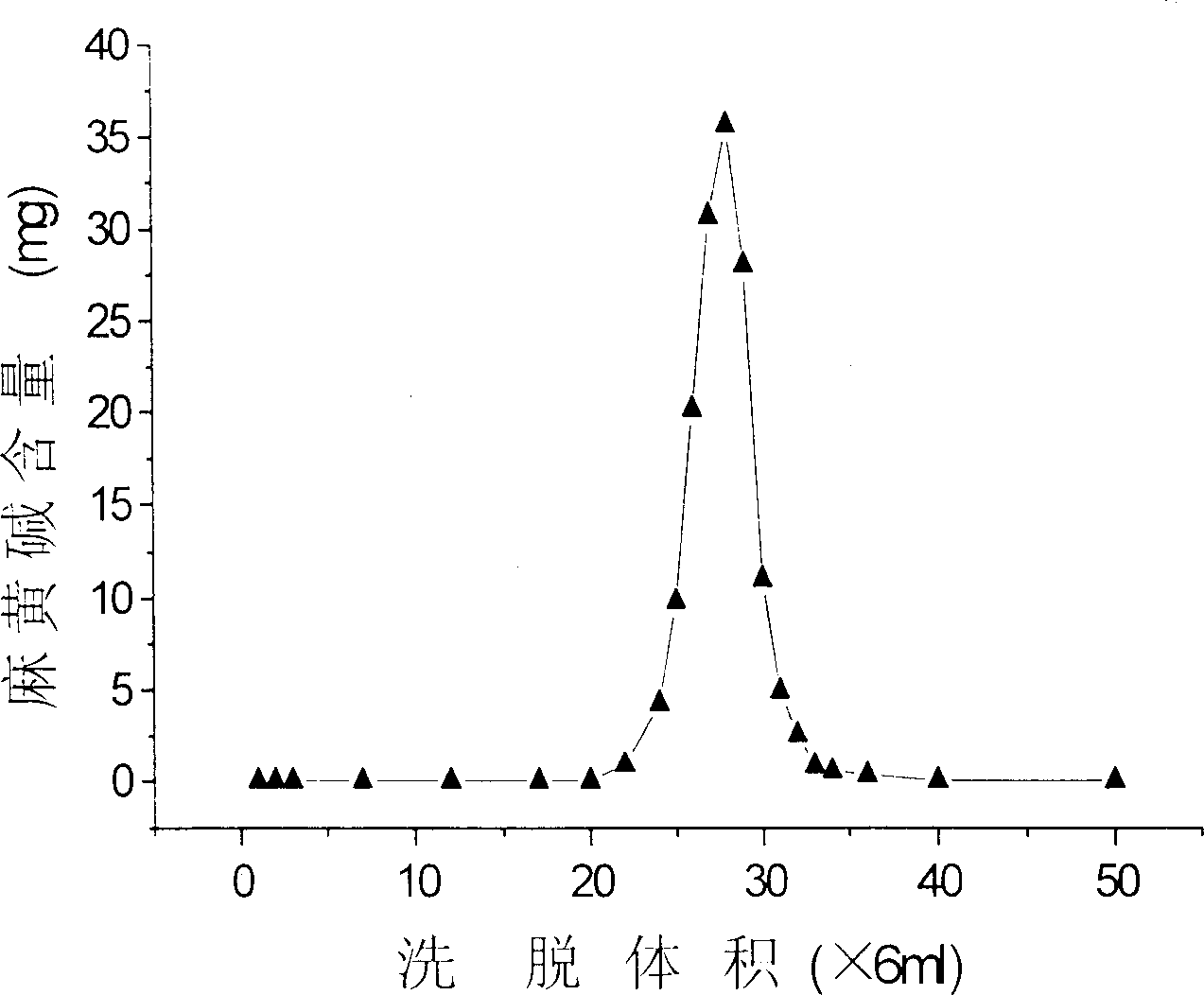

[0027] After pulverizing 25 grams of Ephedra herbae, its particle size reaches 5 mm, add 100 milliliters of water to mix, then place the mixed solution in the ultrasonic generator container, and use ultrasonic waves to extract the Ephedra herba powder; the ultrasonic frequency used is 20KHz, and the power Ultrasonic extraction of 50W was used for 30 minutes, and the medicinal residues were removed by filtration; the filtrate was adjusted to a pH of 9 with 0.5N NaOH, and the filtrate was passed through the D151 weakly acidic cation exchange resin produced by Nankai University Chemical Factory, and the flow rate of the filtrate through resin column exchange and adsorption was 0.5 ml / min: after the exchange is completed, elute with 0.01N hydrochloric acid, detect with a high-performance liquid phase detector during the elution, and stop adding the eluent (such as figure 1 Shown), the eluate is concentrated under reduced pressure to obtain ephedrine hydrochloride crystals.

[0028...

Embodiment 2

[0030] After crushing 25 grams of Ephedra herbae, its particle size reaches 3 mm, add 100 milliliters of 0.001N hydrochloric acid solution to mix, then put the mixed solution in the ultrasonic generator container, and use ultrasonic waves to ultrasonically extract the Ephedra herba powder; Ultrasonic extraction at 20KHz, power 50W for 30 minutes, filter to remove medicinal residues; adjust the pH of the leachate to 14 with 0.5N NaOH, pass the filtrate through the Amberlite XAD-7 macroporous resin column of Rohm & Haas Company, and exchange the filtrate through the resin column, The flow rate of adsorption is 100 ml / min; after the adsorption is completed, use a 2:1 mixed solution of 0.01N hydrochloric acid and ethanol for elution, and use a high-performance liquid phase detector to detect during the elution process, and stop adding eluent at the end of the elution (Such as figure 1 Shown), the eluent is concentrated under reduced pressure to obtain ephedrine hydrochloride cryst...

Embodiment 3

[0033] After pulverizing 25 grams of Ephedra herbaceae, its particle size reaches 2 mm, add 100 milliliters of 0.005N sodium hydroxide solution and mix, then place the mixed solution in an ultrasonic generator container, and use ultrasonic waves to ultrasonically extract the Ephedra herbaceae powder; the frequency used Ultrasonic extraction at 20KHz and power of 50W for 30 minutes, filtering to remove medicinal residues; the filtrate was adjusted to pH 12 with 0.5N NaOH, and then the filtrate was passed through the Amberlite XAD-7 macroporous resin column of Rohm & Haas Company, and the filtrate was passed through the resin column The flow rate of exchange and adsorption is 70 ml / min; after the exchange is completed, use 0.002N hydrochloric acid and acetone at a volume ratio of 1:0.2 for elution. eluent (such as figure 1 Shown), the eluate is concentrated under reduced pressure to obtain ephedrine hydrochloride crystals.

[0034] The used resin column can be used repeatedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com