Method of manufacturing monolithic integration of movable micro physical construction on monocrystalline silicon substrate

A micromechanical structure, monolithic integration technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of increased process difficulty, difficult control, and reduced yield, and achieves easy large-scale integration, The effect of low manufacturing cost and easy operation and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

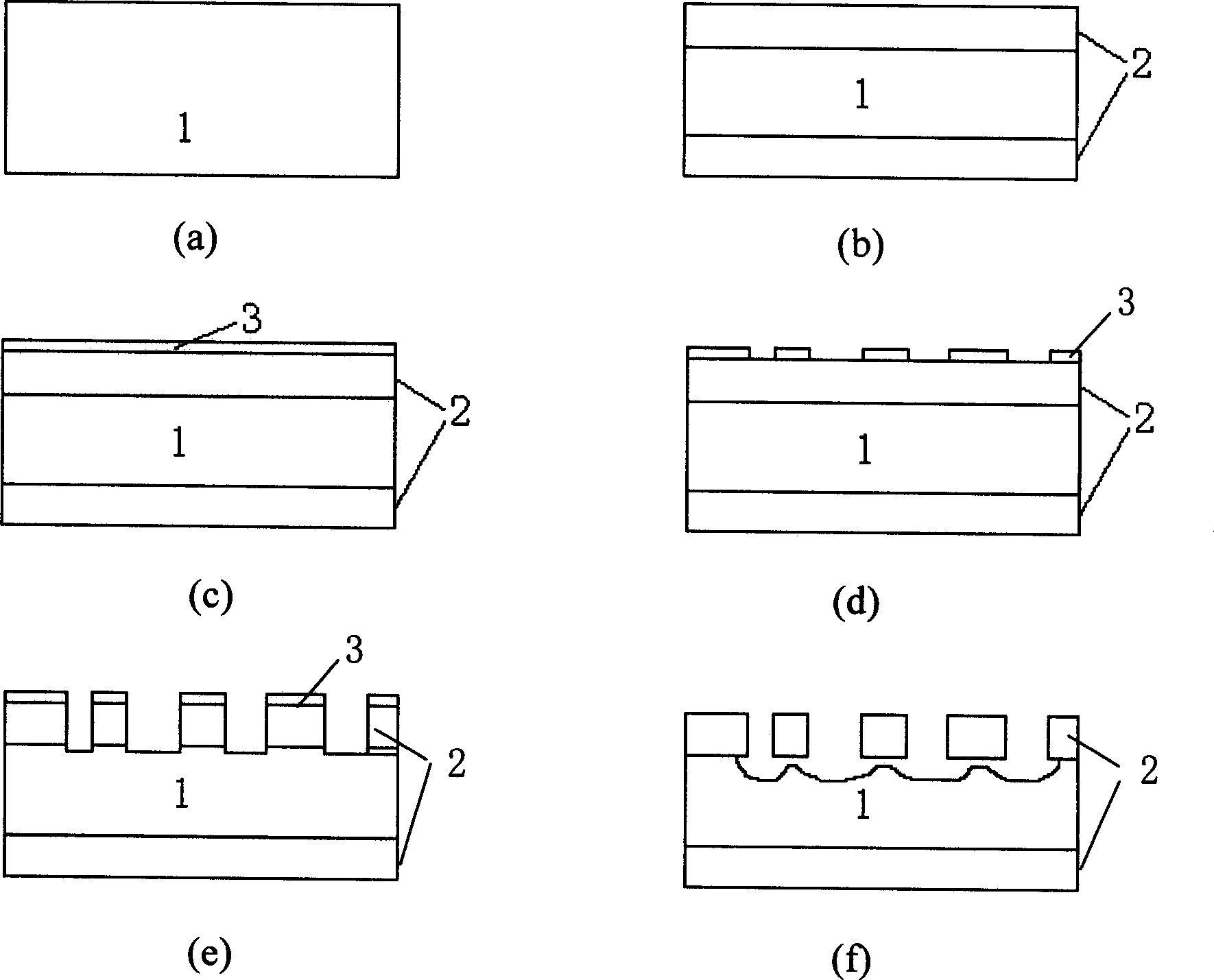

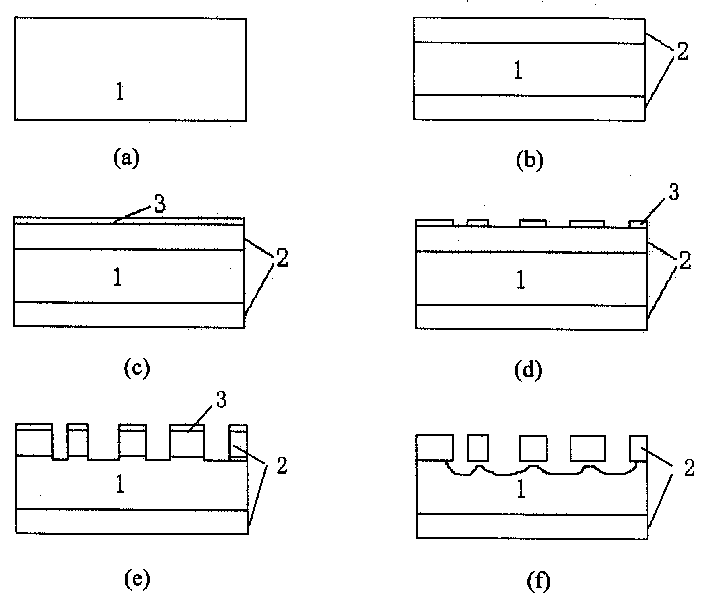

[0020] (1) Single-sided polishing of N-type monocrystalline silicon wafer 1 on a commercially available general-purpose polishing machine, such as figure 1 -(a).

[0021] (2) At 1175°C, use a solid boron source to diffuse concentrated boron on the double-sided deep junction of N-type single crystal silicon wafer 1 to form a boron-rich diffused P-type layer 2, forming an electrically insulating PN junction, and boron-rich diffused P-type layer 2 The junction depth is greater than 40μm, and the concentration of concentrated boron diffusion is greater than 1×10 19 cm -3 ,Such as figure 1 -(b).

[0022] (3) A layer of positive AZ1450 type photoresist 3 is coated on the concentrated boron diffused P-type layer 2, and the thickness of the coated photoresist 3 is 1 μm, such as figure 1 -(c).

[0023] (4) Photoetching the photoresist 3 on the surface of the polished P-type layer 2 to form a suspended movable microstructure pattern, such as figure 1 -(d).

[0024] (5) Using the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com