Electrochemical battery using multicomponent composite membrane

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve problems such as unsatisfactory anti-ionic conductivity, plasticizer environmental hazards, weakening the interface bond strength between the porous polymer layer and the gellable layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The preparation method of the multi-component composite membrane in the present invention is: coating the above-mentioned gelatable polymer solution on the carrier layer film, forming a gelled polymer layer on one side or both sides of the carrier layer, by pulling Stretching, micropores are formed on the carrier layer and the gellable layer, and finally the carrier layer and the gellable layer are tightly bonded into one body, and there is no interface between them.

[0074] More specifically, the preparation of the multi-component composite membrane is carried out according to the following steps.

[0075] a) providing a polymeric carrier layer film;

[0076] b) dissolving the gellable polymer in a solvent to prepare a gellable polymer solution;

[0077] c) coating the solution obtained in step b) on the carrier layer film a), to form a gelable polymer layer on one or both sides of the carrier layer film, a multi-layer film;

[0078] d) Stretching the multilayer fil...

Embodiment 1

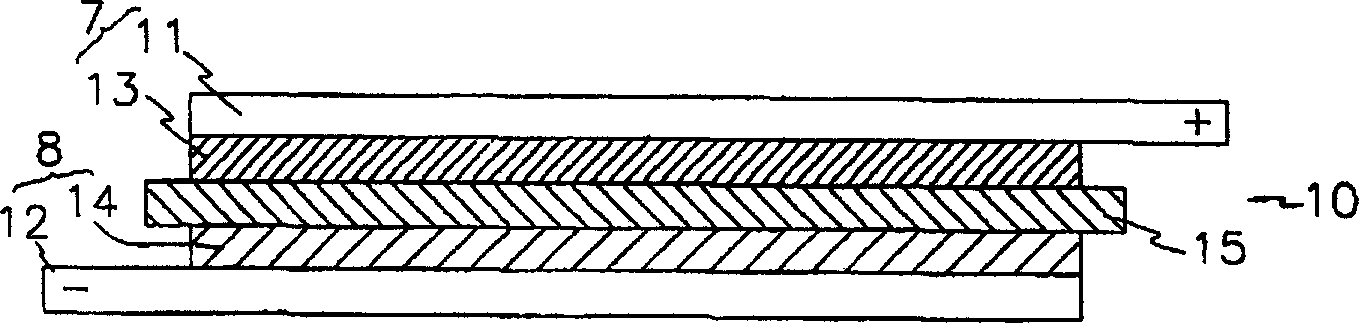

[0117] Preparation of a stacked cell in which a complete cell serves as a basic unit

[0118] (Preparation of positive electrode)

[0119] LiCoO 2 , carbon black, and PVDF (polyvinylidene fluoride) are dispersed in 1-methyl-2-pyrrolidone at a weight ratio of 95:2.5:2.5 to prepare a slurry, and coat the slurry on both sides of the aluminum foil , fully dried at 130°C, and then pressed to obtain a positive electrode with a thickness of 115 microns

[0120] (Preparation of Negative Electrode)

[0121] Graphite, acetylene black, and PVDF are dispersed in 1-methyl-2-pyrrolidinone at a weight ratio of 93:1:6 to prepare a slurry, which is coated on both sides of copper foil and heated at 130°C fully dried under the sun, and then laminated to obtain a negative electrode with a thickness of 120 microns

[0122] (Preparation of multi-component composite membrane)

[0123] Using high crystalline polypropylene as the matrix material, the melt index is 2.0 g / 10 minutes, the density is...

Embodiment 2

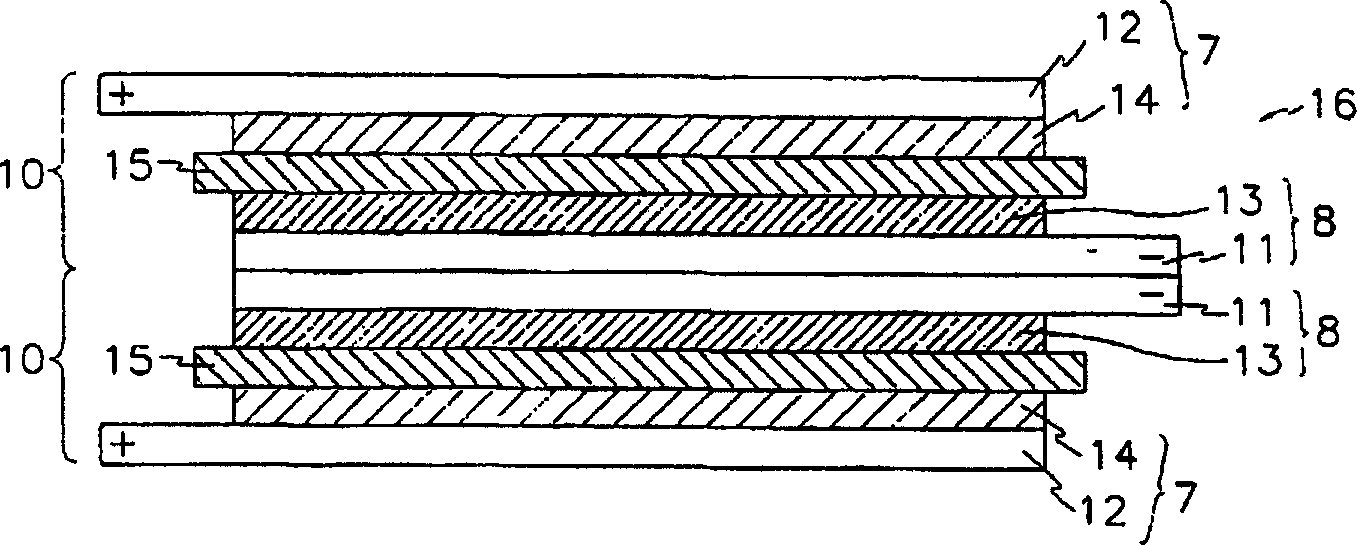

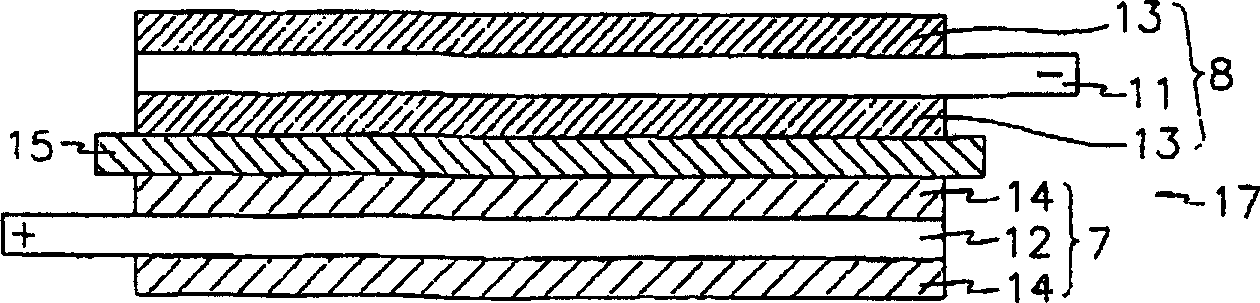

[0138] Fabrication of stacked batteries with dual single cells as basic units

[0139] (Preparation of positive electrode)

[0140] The preparation method of positive pole is identical with example 1;

[0141] The positive electrode placed inside the dual cell battery is prepared by coating the slurry on both sides of the aluminum foil, that is, there are active positive electrode materials on both sides of the aluminum positive current collector plate. The thickness of the positive electrode is 140 microns;

[0142] (Preparation of Negative Electrode)

[0143] The preparation method of negative pole is identical with example 1;

[0144] The negative electrode is the outermost of the complete single battery placed on the outermost side, and is made by coating the active negative electrode material on both sides of the copper negative current collector plate. The negative electrode placed on the inside is made by coating the active negative electrode material on both sides ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com