Humic acid long-acting compound fertilizer and its preparing method

A humic acid and compound fertilizer technology, applied in urea compound fertilizer, nitrogen fertilizer, organic fertilizer, etc., can solve the problems of loss of slow release performance, humic acid coating layer does not have waterproof performance, waste of formaldehyde, etc., to reduce the broken rate , reduce the fixed ratio, increase the effect of fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

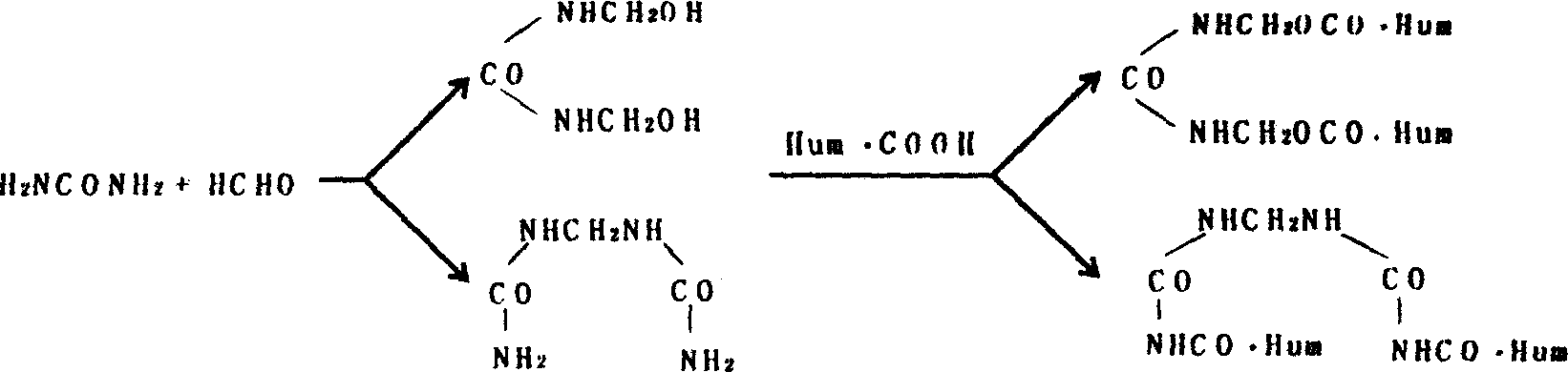

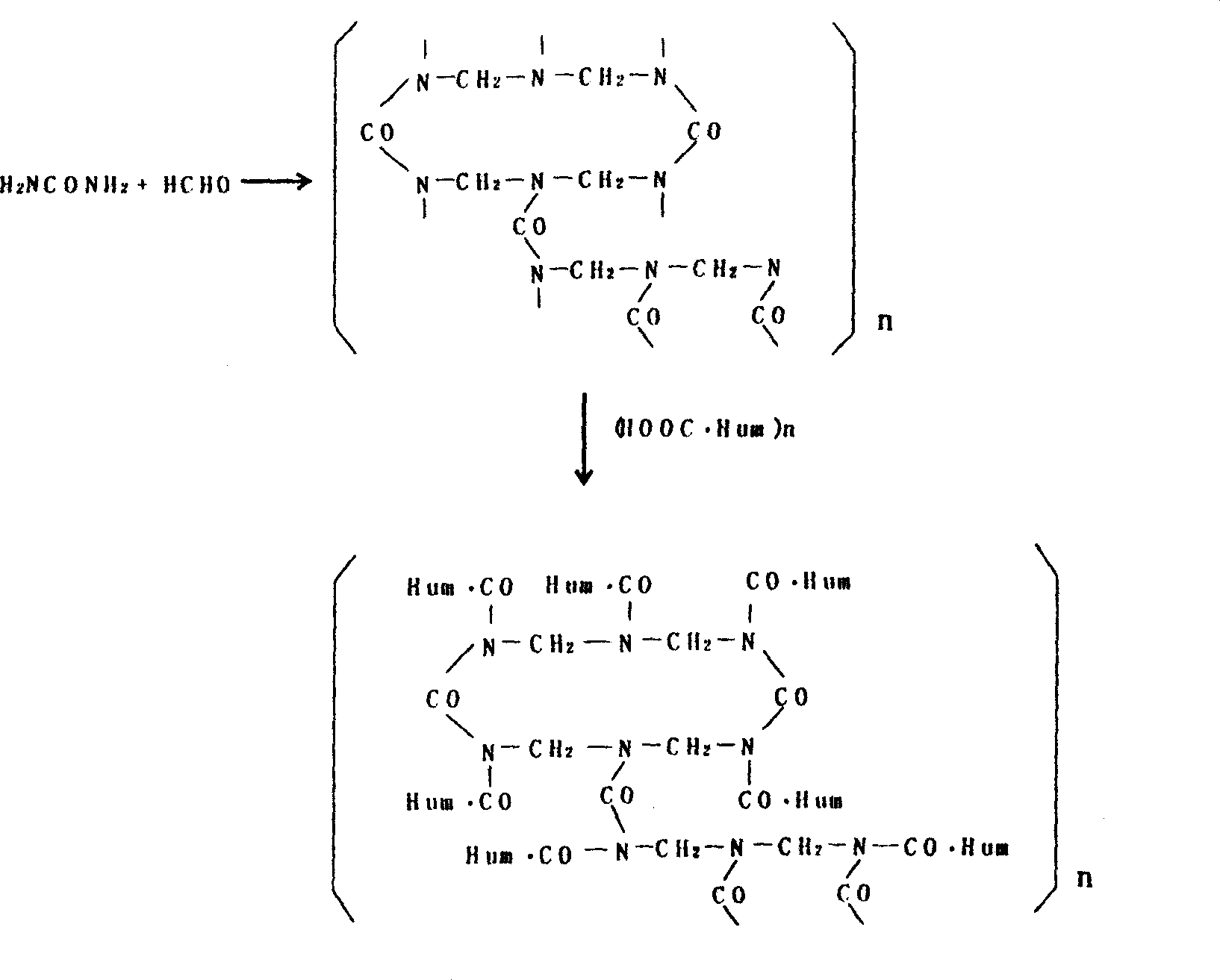

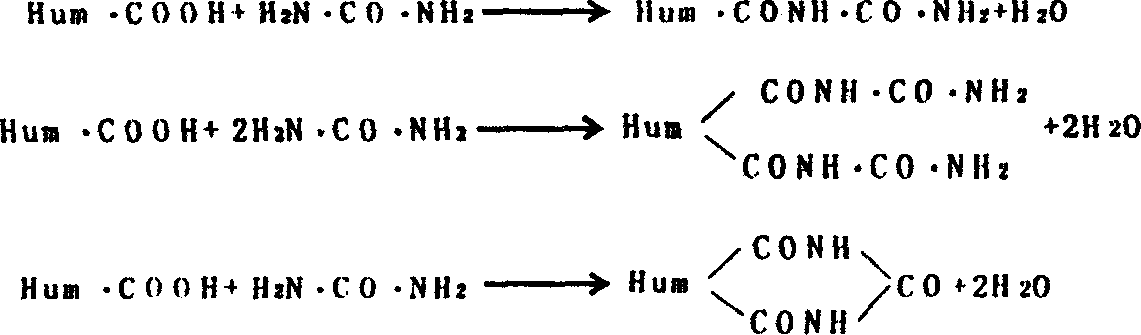

Method used

Image

Examples

Embodiment 1

[0028] Humic acid long-acting compound fertilizer of the present invention, its composition by weight ratio, is made up of 25~40 parts of humic acid urea-formaldehyde complexes and 7560 parts of soluble nitrogen, phosphorus and potassium fertilizers, wherein: the weight ratio between soluble nitrogen, phosphorus and potassium fertilizers 12~25: 30~40: 10~20; the raw materials of the humic acid urea formaldehyde complex are calculated by weight ratio, consisting of 15~30 parts of peat powder, 31~46 parts of urea, 1~2 parts of ammonium chloride And 36~42 parts concentration is the formaldehyde composition of 30%.

[0029] The preparation of its humic acid nitrogen fertilizer complex:

[0030] Using peat powder, urea, ammonium chloride and formaldehyde as raw materials, first condense urea and formaldehyde (molar molecular ratio: 1:2.0-2.5) in an alkaline solution (pH 7-8) at 50-95°C for 5- 30 minutes;

[0031] Then add ammonium chloride to adjust the pH of the solution to 4-5;...

Embodiment 2

[0043] The preparation process of the humic acid urea-formaldehyde complex is the same as in Example 1, the difference is that at first 12 kilograms of urea and 42 kilograms of 30% industrial formaldehyde (molar ratio is 1: 2.1) are mixed, and then with saturated NaOH solution Adjust the pH of the mixed solution to 7.5, and condense for 20 minutes at a solution temperature of 60-70°C; then add 2 kg of ammonium chloride to adjust the pH of the solution to 4-5; continue to add 24 kg of urea to the solution, At this time, the molar ratio of urea to formaldehyde is 1.4:1, keep the solution temperature at 65-75°C, and continue to condense urea and formaldehyde for 0.2 hours; then slowly add 20 kg of 60-mesh peat powder, and keep stirring to keep the temperature of the mixture at 1.5 hours at 70-80°C, the product was air-dried, dried, crushed and passed through an 80-mesh sieve to obtain a gray-black powder humic acid urea-formaldehyde complex.

[0044] 33.5 kilograms of humic acid ...

Embodiment 3

[0046] The preparation process of humic acid urea-formaldehyde complex is the same as in Example 1, but the difference is that at first 9 kilograms of urea and 36 kilograms of 30% industrial formaldehyde (molar molecular ratio is 1: 2.4) are mixed, and then mixed with saturated NaOH solution Adjust the pH of the mixed solution to 7.8, and condense for 10 minutes at a solution temperature of 80 to 90°C; then add 1 kg of ammonium chloride to adjust the pH of the solution to 4 to 5; continue to add 24 kg of urea to the solution. When the molar ratio of urea and formaldehyde is 1.5:1, keep the solution temperature at 70-80°C, and continue to condense urea and formaldehyde for 0.5 hours; then slowly add 30 kg of 60-mesh peat powder, and keep stirring to keep the temperature of the mixture at 80°C. ~90°C for 0.5 hours, the product was air-dried, dried, crushed and passed through an 80-mesh sieve to obtain a gray-black powder humic acid urea-formaldehyde complex.

[0047] 40 kilogram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com