Method of preparing ethanol through cellulose solid phase enzymolysis and liquid fermentation coupling and its installation

A liquid fermentation and cellulose technology, which is applied in biochemical equipment and methods, enzymology/microbiology devices, bioreactor/fermenter combinations, etc. Problems such as large water content, to achieve the effect of reducing feedback inhibition and avoiding inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

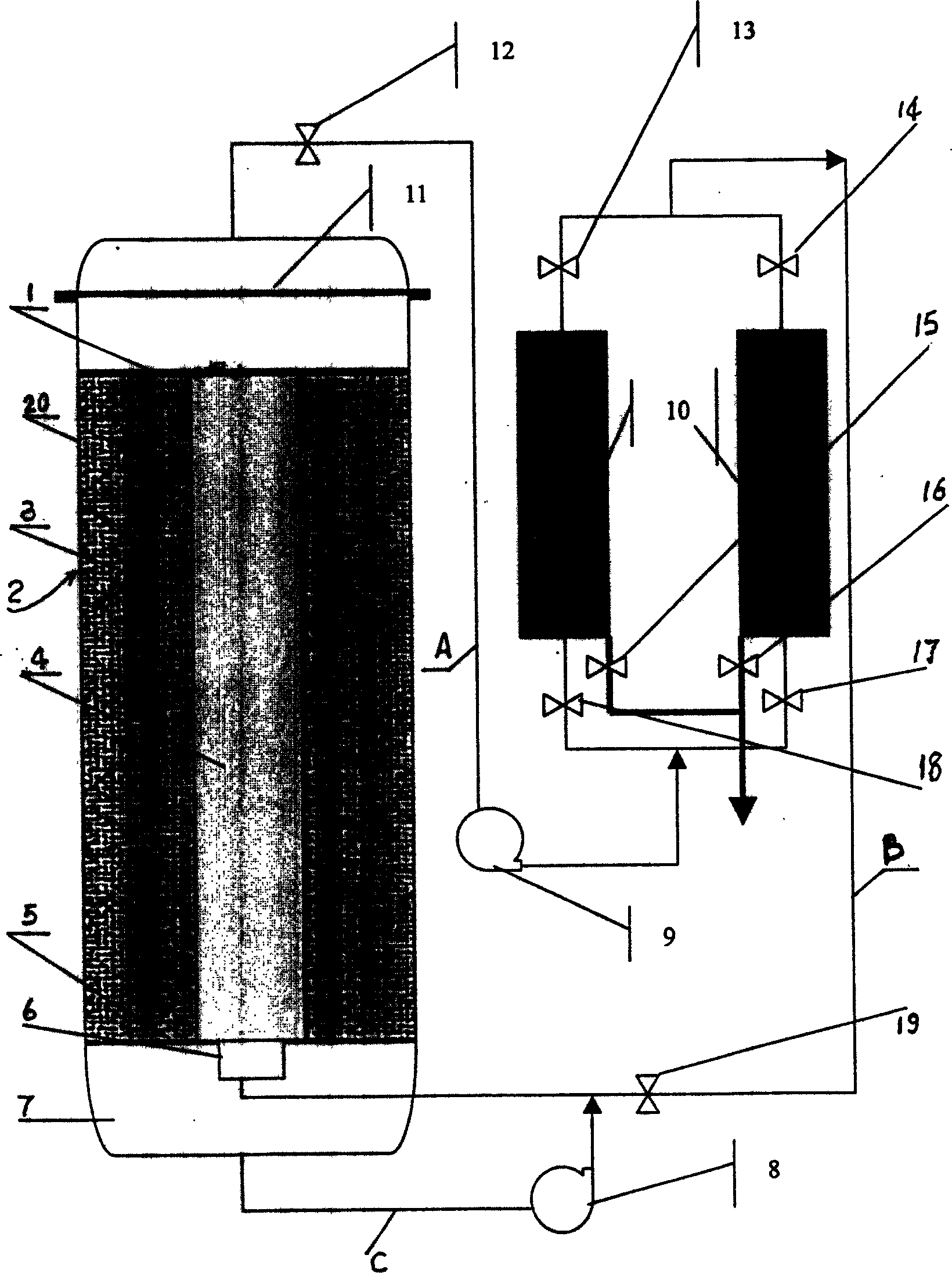

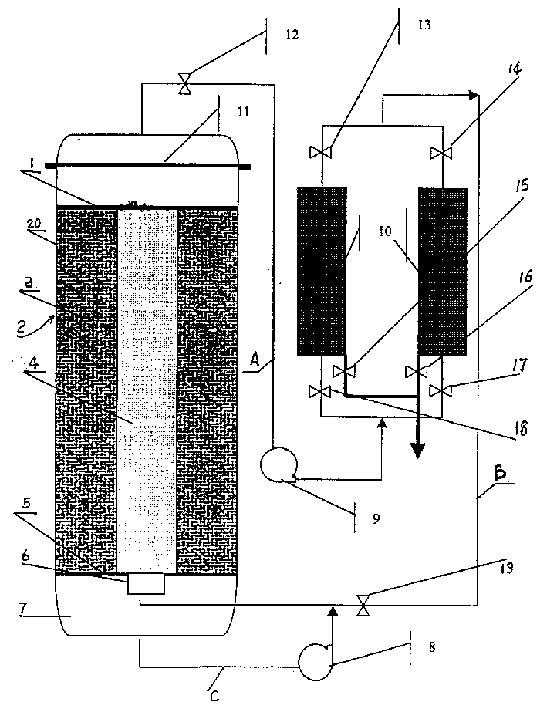

[0035] The height-to-diameter ratio of the cellulose solid-phase enzymolysis-liquid fermentation reactor 2 of the present embodiment is 12, two ethanol adsorption columns 10 are used in parallel, the volume ratio of the outer cylinder 20 and the inner cylinder 4 is 1:5, and the outer cylinder 20 The height-to-diameter ratio of the inner cylinder 4 is 10, the height-to-diameter ratio of the inner cylinder 4 is 50, and the height-to-diameter ratio of the upper head 11 is 0.5;

[0036] Its preparation ethanol step is as follows:

[0037] 1. Add sterilized cellulose raw material and cellulase into cavity 3, keep at 40°C for 40 hours to generate cellulose hydrolyzate;

[0038] 2. From the top of the cavity between the inner and outer cylinders, rinse the cellulose enzymatic hydrolyzate in the cavity with sterile water, and the obtained enzymatic liquid flows into the lower head 7 located at the lower end of the main body of the reactor, and circulates with an enzymatic liquid The ...

Embodiment 2

[0047] Using the device for preparing ethanol by coupling solid-phase enzymatic hydrolysis of cellulose-liquid fermentation in Example 1, the solid-phase enzymatic hydrolysis of cellulose, liquid fermentation and ethanol recovery are carried out according to the following steps, and the specific steps are as follows:

[0048] a. Put the wheat straw raw material treated by non-polluting steam explosion into the cavity 3 between the inner and outer cylinders of the solid-phase enzymatic hydrolysis-liquid fermentation reactor 2, pass through 0.1Mpa high-pressure steam to sterilize for 30min, and cool to 50°C , add 10IU filter paper enzyme activity / g pretreated cellulose raw material according to aseptic operation, and incubate at 40°C for 30hr;

[0049] b. Rinse the cellulose hydrolyzate in the cavity 3 between the inner and outer cylinders with sterile water, store the obtained enzymolyzate in the lower head 7, and pump the enzymolyzate into the inner cylinder 4 with the enzymoly...

Embodiment 3

[0055] Make a cellulose solid-phase enzymatic hydrolysis-liquid fermentation coupled device for preparing ethanol. The height-to-diameter ratio of the cellulose solid-phase enzymatic hydrolysis-liquid fermentation reactor 2 in this embodiment is 15, and four ethanol adsorption columns 10 are used in parallel. The volume ratio of the cylinder 20 and the inner cylinder 4 is 1:8, the height-diameter ratio of the outer cylinder 20 is 12, the height-diameter ratio of the inner cylinder 4 is 55, and the height-diameter ratio of the upper head 11 is 0.2;

[0056] Add cellulose raw materials and cellulase to the cavity 3 between the inner and outer cylinders (the solid-phase enzymatic hydrolysis area of cellulose) to carry out solid-phase enzymatic hydrolysis of cellulose, and the enzymatic hydrolyzate produced is rinsed and filtered by the lower filter plate 5 before entering the The lower head 7 is stored; in the inner cylinder 4, the enzymolysis solution pumped in from the lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com