Environment-protecting pollution-free production method of dioscorea saporin

A diosgenin and pollution-free technology, which is applied in the field of environmentally friendly and pollution-free production of diosgenin, can solve problems such as pollution, organic waste water discharge, and environmental pollution, and achieve the goals of solving environmental pollution problems, reducing waste water discharge, and effectively utilizing resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

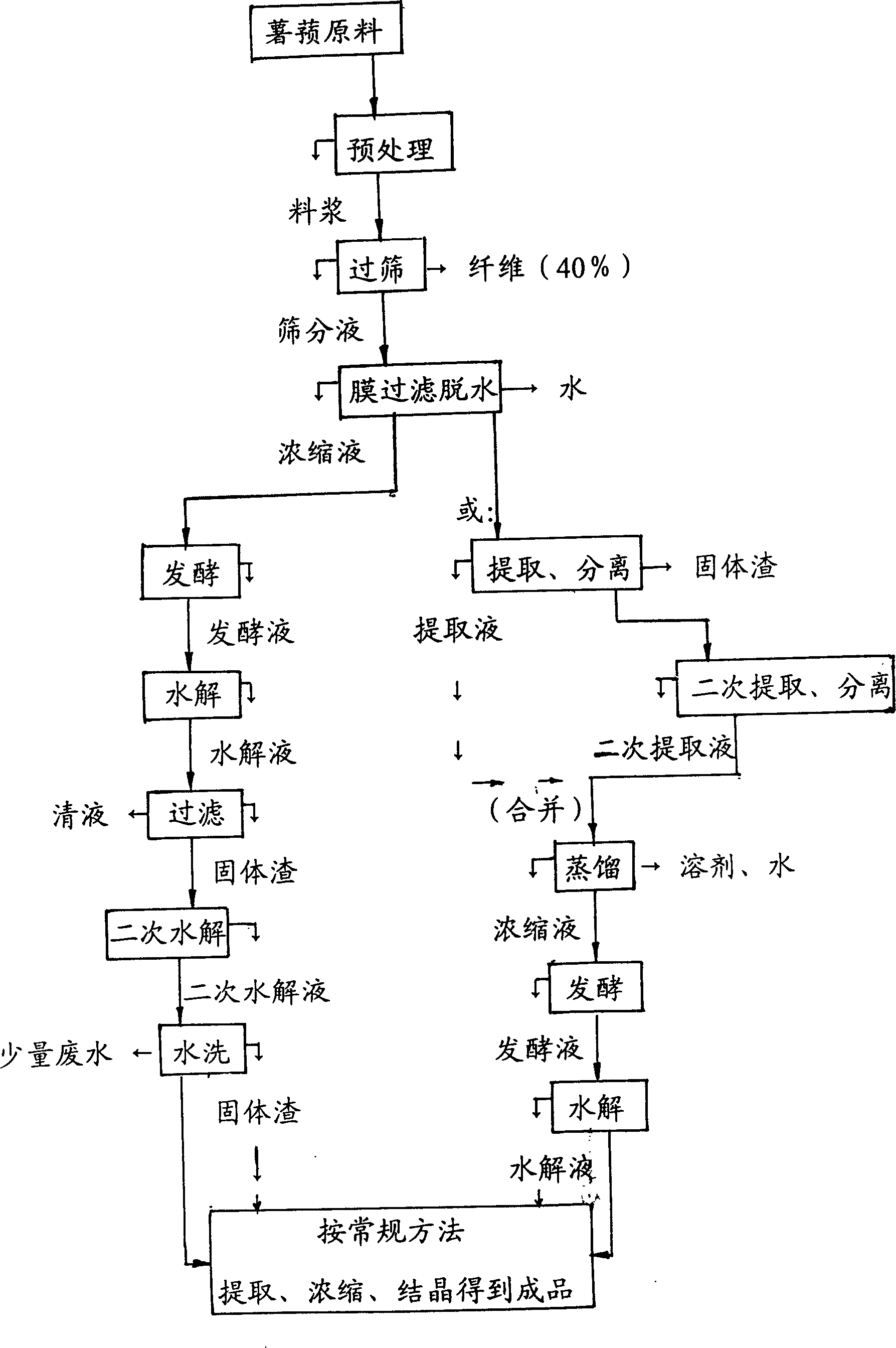

[0028] The method comprises the steps in turn:

[0029] (1) Raw material pretreatment: wash the raw material with clear water, crush it with a hammer crusher, grind it into a slurry with a mill,

[0030] (2) sieving: use 40-200 mesh vibrating sieves to sieve about 40% plant fibers (the screened out is used as organic fertilizer and fuel),

[0031] (3) Membrane filtration dehydration: remove about 70% of water with ultrafiltration membrane (molecule with a molecular weight cut-off of 400 or more) to form a concentrate,

[0032] (4) Fermentation: in the fermenter, under the condition of 25-45°C, ferment naturally for 48 hours,

[0033] (5) Hydrolysis: add hydrochloric acid or sulfuric acid to make the fermentation broth to PH<2, measure the PH value while adding hydrochloric acid or sulfuric acid during operation, generally choose PH=1, PH=1.5 or PH=1.8, pressurize (0.3Mpa) Hydrolyzed for 0.5 hours,

[0034] (6) Filtration: the clear liquid is filtered out for comprehensive u...

Embodiment 2

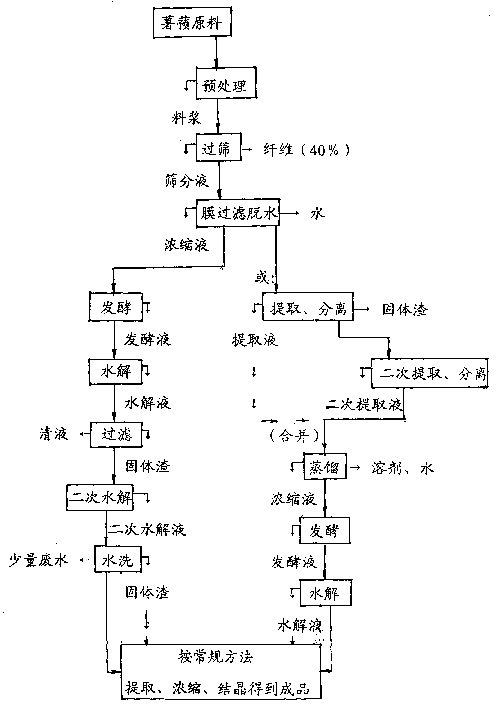

[0039] The method comprises the steps in turn:

[0040] (1) Raw material pretreatment: wash the raw material with clear water, crush it with a hammer crusher, grind it into a slurry with a mill,

[0041] (2) sieving: use 40-200 mesh vibrating sieves to sieve about 40% plant fibers (the screened out is used as organic fertilizer and fuel),

[0042] (3) Membrane filtration dehydration: remove about 70% of water with ultrafiltration membrane (molecule with a molecular weight cut-off of 400 or more) to form a concentrate,

[0043] (4) Extraction and separation: the concentrated solution can be extracted with 45-90% solvent methanol, ethanol, propanol, pentanol or acetone for 0.5 hour, and then centrifuged,

[0044] (5) Secondary extraction and separation: the solid slag separated by extraction can be extracted once with any of 45-90% solvent methanol, ethanol, propanol, amyl alcohol or acetone.

[0045] (6) Distillation: Combine the two extracts, and after the solvent is recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com