High-molecular electrolyte fuel cell

A polymer electrolyte and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve problems such as degradation of battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

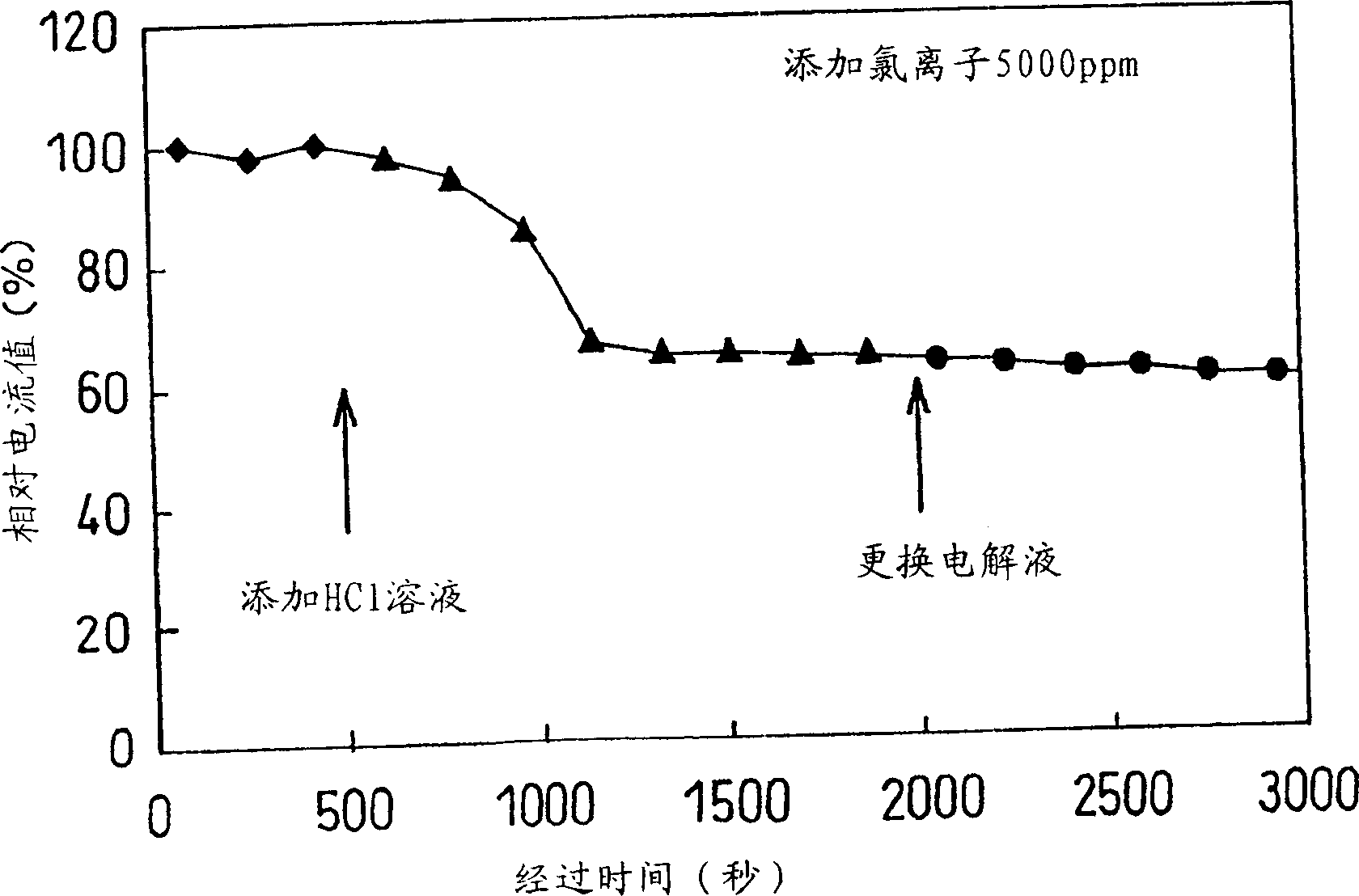

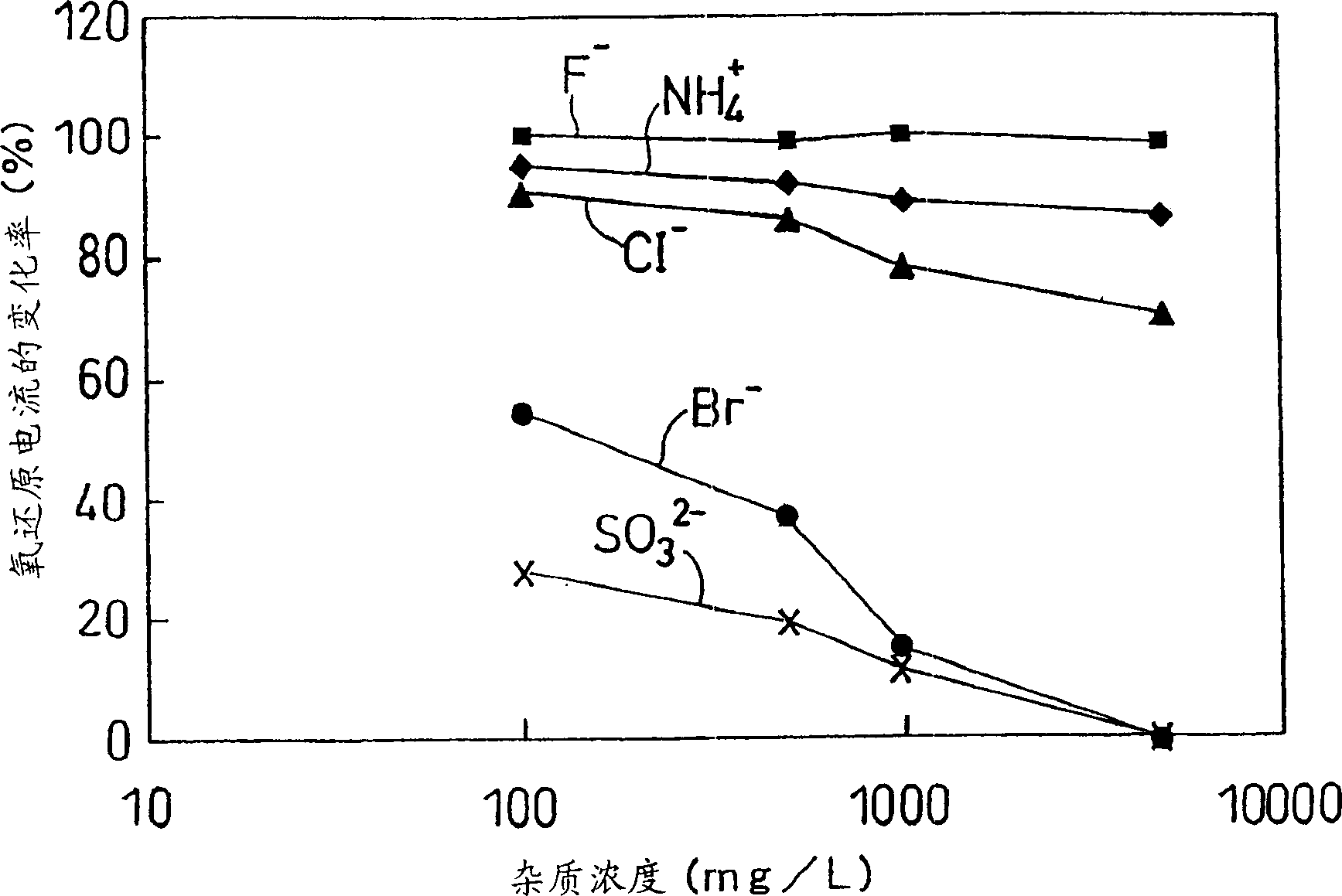

[0087]The fuel cell of this embodiment is characterized by controlling the types and amounts of impurities eluted from the conductive separator and causing deterioration of the fuel cell characteristics, and when the separator contains impurities, these impurities are removed to a certain level. Level.

[0088] The impurities eluted from the separator include sulfite ion, chloride ion, bromide ion, ammonium ion and TOC. Among them, TOC (total or ganic carbon) represents the amount of carbon in organic matter present in water, and is also called organic carbon. Hereinafter, TOC is also simply referred to as organic matter.

[0089] In the long-term operation of the fuel cell, the impurity substances are eluted and accumulated in small amounts every time, which continuously deteriorates the battery characteristics. However, in a conductive separator subjected to a predetermined cleaning treatment, since the content of ions and organic matter is greatly reduced, a fuel cell using the...

Embodiment approach 2

[0146] The present invention is characterized in the following aspects: it is stipulated to limit the types and amounts of impurities eluted from the gasket composed of the sealing material and cause the deterioration of the fuel cell characteristics, and to remove them to a certain level when the gasket contains impurities.

[0147] The impurities eluted from the gasket include sulfide ions, sulfite ions, chloride ions, bromide ions, ammonium ions, TOC and so on.

[0148] During the long-term operation of the fuel cell, the above-mentioned impurities are eluted and accumulated in small amounts every time, which continuously deteriorates the battery characteristics. However, in the gasket subjected to a predetermined cleaning process, the content of ions and organic substances is greatly reduced, so a fuel cell using the gasket can maintain high cell characteristics.

[0149] As the sealing material constituting the gasket, fluororubber, silicone rubber, natural rubber, EPDM, buty...

Embodiment 1~26、 comparative example 1~45

[0169] (i) Manufacturing method of electrode electrolyte membrane assembly (MEA)

[0170] use Figure 5 The method of manufacturing the electrode electrolyte membrane assembly (MEA) used in this example will be described. Figure 5 It is a longitudinal cross-sectional view showing the structure of the MEA.

[0171] The MEA 15 includes an electrode 13 composed of a diffusion layer 11 and a catalyst layer 12 formed on one surface thereof, and a polymer electrolyte membrane 14 sandwiched by a pair of electrodes 13. The diffusion layer 11 uses carbon paper or carbon nonwoven fabric.

[0172] 25% by weight of platinum particles with an average particle diameter of about 30 angstroms are supported on the acetylene black powder and used as the electrode catalyst powder. The liquid obtained by dispersing the catalyst powder in isopropanol is mixed with the solution obtained by dispersing the powder of perfluorocarbon sulfonic acid in ethanol to obtain a catalyst blade.

[0173] The carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com