Zero discharge and regeneration recovery system of steam-electric sweetener

A technology of desulfurization equipment and recovery system, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of consuming filter material, waste of heat source, inconvenience, etc., and achieves fast processing, space saving, and good environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

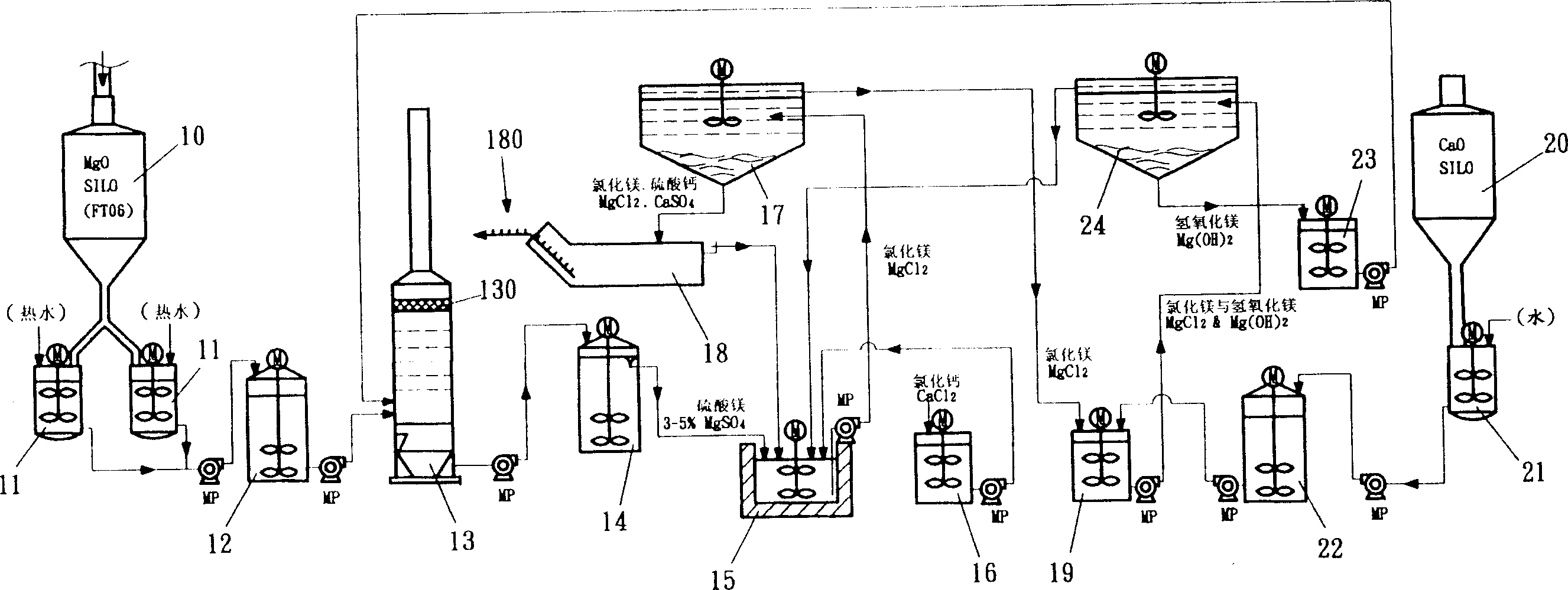

[0019] The composition of the steam-electric desulfurization equipment zero-emission and regeneration recovery system of the present invention is described in detail below in conjunction with the accompanying drawings:

[0020] Such as figure 1 As shown, the steam-electric desulfurization equipment zero discharge and regeneration recovery system of the present invention comprises: magnesium oxide storage tank 10, magnesium oxide (MgO) pyrolysis tank 11, magnesium hydroxide (MgOH) 2 ) storage tank 12, absorption tower 13, oxidation tank 14, bottom ash stirring tank 15, calcium chloride (CaCl 2 ) storage tank 16, first settling tank 24, boiler water seal 18, reaction tank 19, calcium oxide storage tank 20, calcium oxide (CaO) stirring tank 21, calcium hydroxide storage tank 22, magnesium hydroxide buffer tank 23, the first Two settling tanks 17 are formed; the method flow of its systematic arrangement, processing is:

[0021] Magnesia storage tank 10: stores magnesium oxide (M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com