Solid strong acid catalyst and its preparing method

A solid strong acid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low isomerization selectivity and many cracking products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the catalyst provided by the invention comprises mixing the hydrated zirconia with monoclinic and tetragonal mixed crystal phases, the mixture of silicon oxide and aluminum oxide, and using sulfuric acid, ammonium sulfate or hydrogen sulfate with a concentration of 0.1-4.0 mol / liter The ammonium aqueous solution is impregnated, the solid is dried and shaped, and then roasted at 400-800°C.

[0017] The above shaped and calcined solids are further impregnated with a solution containing Group VIII metals, dried and calcined at 400-700° C. to obtain a catalyst supporting Group VIII metals.

[0018] The method of introducing Group VIII metal can be carried out by conventional impregnation method, that is, the soluble Group VIII metal compound is formulated into an impregnation liquid to impregnate solid substances. The liquid / solid ratio is 0.8-1.2 during impregnation, the temperature is room temperature, and the time is 2-6 hours. . The soluble Gr...

example 1

[0031] Preparation of hydrated zirconia in mixed crystal phases.

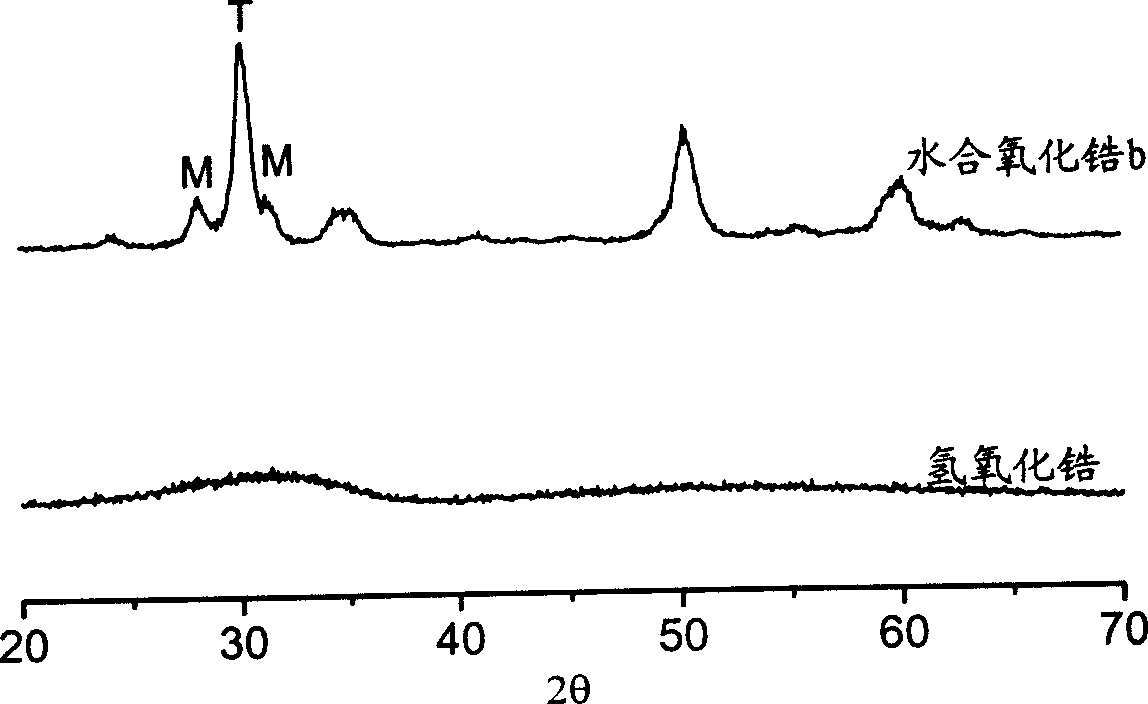

[0032] Zirconium oxychloride (ZrOCl 2 ·8H 2 (0) be made into 5 mass % aqueous solution, while stirring, slowly add the ammoniacal liquor that concentration is 25 mass %, adjust pH value to certain value, move gained zirconium hydroxide precipitation to autoclave sealing together with solution, at set temperature Water heat treatment for a period of time. The solid was washed with deionized water and filtered until the filtrate was free of Cl - . Dry at 110°C for 24 hours to obtain hydrated zirconia powder. The crystal phase composition of hydrated zirconia prepared under different hydrothermal treatment conditions is shown in Table 1. Among them, the X-diffraction spectrum of hydrated zirconia b is shown in figure 1 , figure 1 T represents the diffraction peak of tetragonal zirconia, and M represents the diffraction peak of monoclinic zirconia.

example 2

[0034] A mixture of silica and alumina is prepared.

[0035] Take a certain amount of silica sol (SiO 2 content is 41% by mass) was added to the solid powder of a certain amount of aluminum hydroxide (Germany, Condea company, brand SB), ground uniformly, dried at 110 ° C for 24 hours, and added 10% NH 4 200 ml of Cl solution was refluxed under stirring at 80°C for 3 hours, washed with deionized water, filtered, repeated three times, and dried at 110°C for 24 hours to prepare a mixture of silicon oxide and aluminum oxide. See Table 2 for the amount of raw materials added and the composition of the mixture during preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com