Poly-gamma-glutamic acid generation bacteria and method for producing poly-gamma-glutamic acid

A glutamic acid and strain technology, applied in the field of applied microorganisms, can solve the problems of high fermentation cost, long fermentation period, limited performance application range, etc., and achieve the effects of stable genetic traits, reduced production costs, and fast growth speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

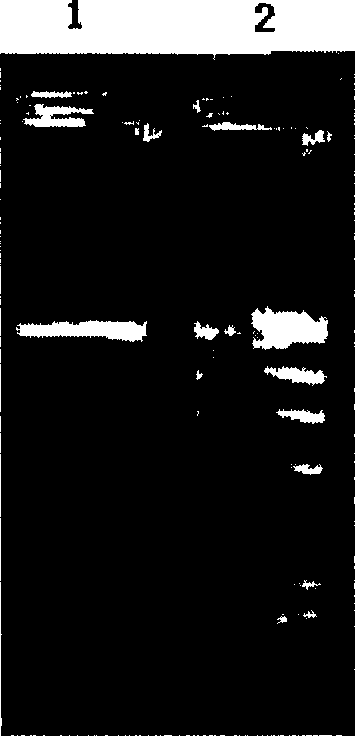

[0047] Example 1: Isolation and identification of poly-γ-glutamic acid producing bacteria X-003:

[0048] Take the soil 5cm below the soil surface of the paddy field in the experimental farm of Huazhong Agricultural University, add an appropriate amount of sterile water, shake well, and dilute it by 100 times. Heat-treat the suspension at 80°C for 15 minutes, and apply LB (LB medium should be added per 1 liter of distilled water. The formula is as follows: peptone 10 g / L, NaCl 10 g / L, yeast extract 5 g / L , agar 20 g / liter, pH7.0) solid plate, through overnight cultivation, pick sticky colonies in 5 milliliters of poly-γ-glutamic acid screening medium E (E medium formula and production: see literature: Cromwick etc., Effect of magnese (II) on Bacillus licheniformis ATCC9945A physiology and poly-(glutamic acid) formation. Int. J. Biol. Macromol. 17: 259-267) cultured for 2-3 days. Centrifuge the culture solution to get the supernatant, precipitate with 3 times the volume of eth...

Embodiment 2

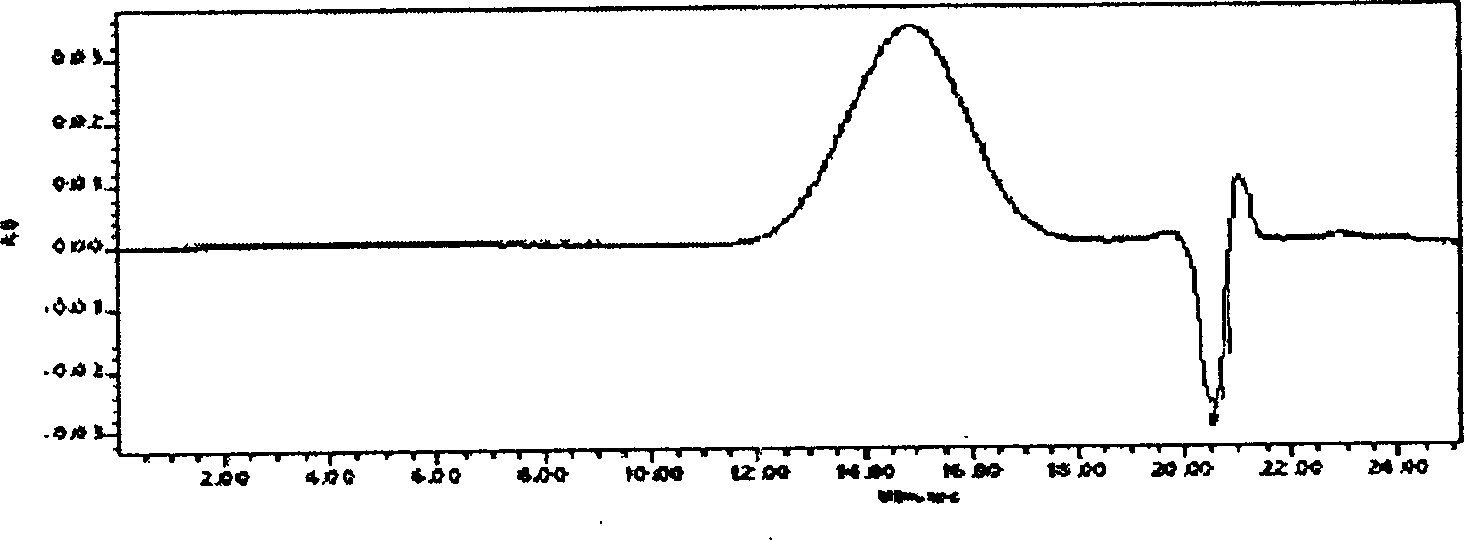

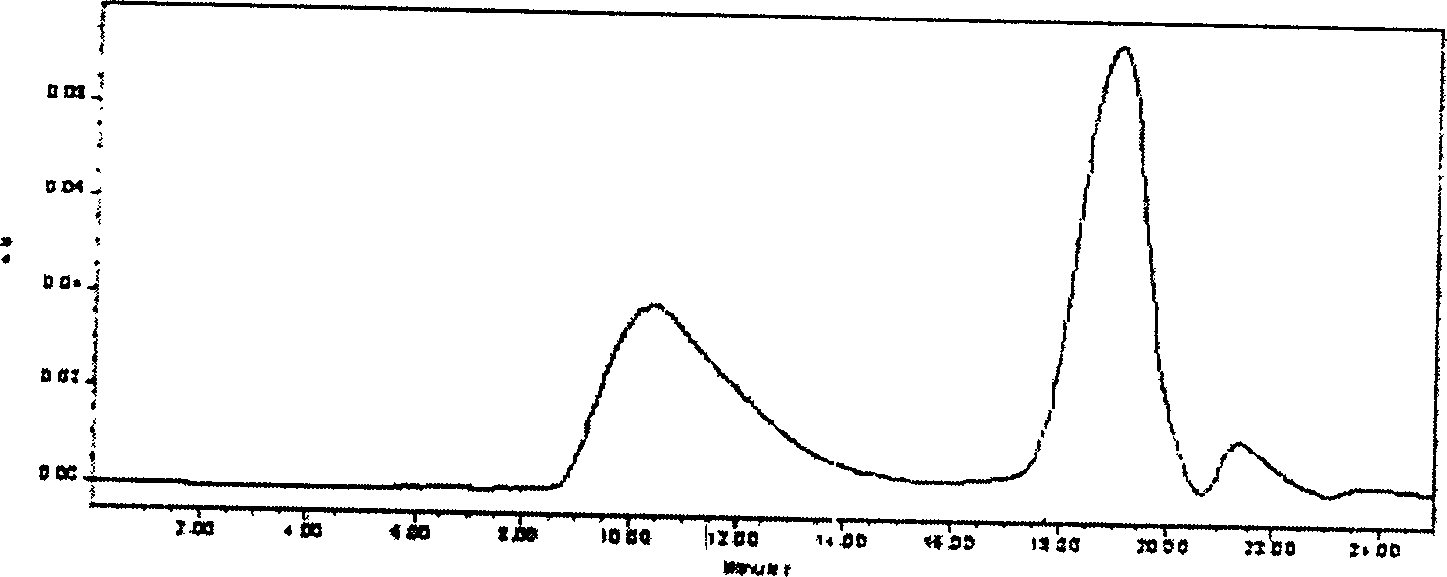

[0050] Embodiment 2: the HPLC analysis method of poly-γ-glutamic acid

[0051] The quantitative analysis and molecular weight determination of poly-γ-glutamic acid were completed by HPLC, chromatographic column: G6000PWXL, mobile phase was 25mM Na 2 SO 4 solution and acetonitrile in a ratio of 4:1. Purified poly-γ-glutamic acid was used as a quantitative standard, and the molecular weight standard was TSK standard Poly (ETHYLENE OXIDE).

[0052] The steps for determining the yield and molecular weight of poly-γ-glutamic acid are as follows: After quantitatively diluting the fermentation broth, adjust the pH value to 3.0, centrifuge at 10,000 rpm for 30 minutes, and collect the supernatant. The diluted fermentation broth was used to detect the concentration and molecular weight. The retention time of the fermentation product poly-γ-glutamic acid is 10min, and the molecular weight is above 10000KD (see figure 2 , 3 ) shown.

Embodiment 3

[0053] Embodiment 3: the liquid batch fermentation production of poly-γ-glutamic acid producing bacteria

[0054] 1. Use the strains preserved in cryovials as the original strains.

[0055] 2. Inclined bacteria

[0056] Inoculate the bacterial strain Bacillus subtilis x-003 preserved in the frozen tube onto the LB solid slant with an inoculation loop (add peptone 10 g / L, NaCl 10 g / L, and yeast extract 5 g to 1 liter of distilled water medium) / L, agar 20 g / L, pH7.0.), cultured at 37°C.

[0057] 3. Seed liquid culture

[0058] Inoculate the activated colony on the solid slant surface of LB (the medium composition is the same as above), inoculate 10 g / L of peptone, 10 g / L of NaCl, and 5 g / L of yeast extract into the medium of 1 liter of distilled water , pH 7.0 in 250 ml Erlenmeyer flasks, the filling volume of each bottle of culture solution is 20-40 ml, culture at 37° C. and 200 rpm for 5-6 hours to the mid-logarithmic growth phase.

[0059] 4. Fermentation tank culture: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com