Tunnel fireproof paint and its manufacturing technology

A technology for fire-resistant coatings and tunnels, which is applied in the direction of fire-resistant coatings and coatings. It can solve the problems of insufficient adaptability to high and low temperature changes in strength, flexibility, water resistance, and acid corrosion resistance, so as to inhibit rapid evaporation and reduce quality problems. Improve the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: 25.0Kg of high-grade cement, 6.2Kg of aluminum tripolyphosphate, 6.5Kg of water glass, 7.5Kg of expanded perlite, 5.0Kg of fly ash glass beads, 2.5Kg of mica powder, 3.7Kg of kaolin, aluminum silicate Add 3.7Kg of fiber, 18.0Kg of aluminum hydroxide, and 16.7Kg of magnesium hydroxide into the mixer in turn and mix evenly, add a small amount of water to infiltrate, then add 5Kg of polyvinyl acetate emulsion, and stir evenly. The inspection methods and inspection items of fire retardant coatings are the same as Table 1. Fire resistance: coating thickness 10mm, fire resistance limit 150min; surface dry time: 3.2h; bonding strength: 0.42Mpa; density: 560Kg / m 3 ; Thermal conductivity: 0.115W / (m·k); Other performance indicators are qualified.

Embodiment 2

[0017] Embodiment 2: 26.0Kg of high-grade cement, 6.8kg of aluminum tripolyphosphate, 6.5Kg of water glass, 9.5Kg of expanded perlite, 7.5Kg of fly ash glass beads, 2.8Kg of mica powder, 4.5Kg of kaolin, aluminum silicate Add 4.3Kg of fiber, 19.6Kg of aluminum hydroxide, and 18.5Kg of magnesium hydroxide to the mixer in turn, mix evenly, add a small amount of water to infiltrate, then add 8.6Kg of acrylate polymer emulsion, and stir evenly. The inspection methods and inspection items of fire retardant coatings are the same as Table 1. Fire resistance: coating thickness 10mm, fire resistance limit 160min; surface dry time: 3.0h; bonding strength: 0.48Mpa; density: 500Kg / m 3 ; Thermal conductivity: 0.114W / (m·k); Other performance indicators are qualified.

Embodiment 3~5

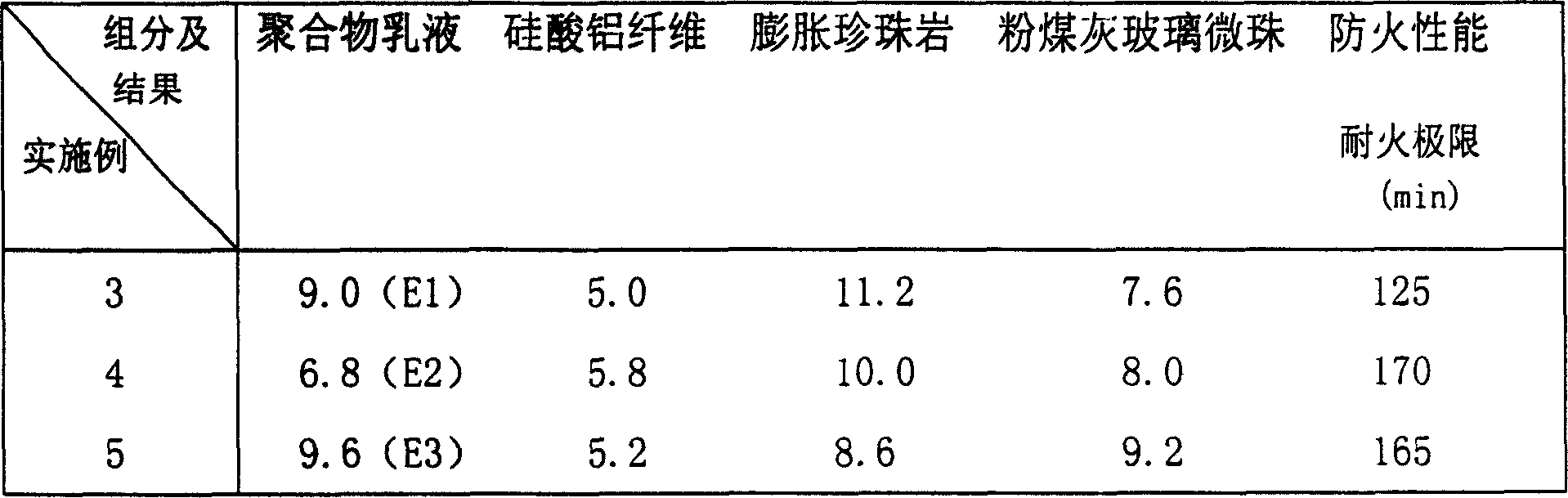

[0018] Embodiment 3~5: the basic formula of fireproof coating and preparation method are the same as embodiment 2, only change the consumption of polymer emulsion, aluminum silicate fiber, expanded perlite, fly ash glass microsphere, result is listed in table 2 (weight share).

[0019] Table 2

[0020]

[0021] *Remarks: 1. The thickness of the coating is 10mm, and the rest of the technical performance indicators are in line with the relevant regulations in Table 1. 2. (E1), (E2), and (E3) in Table 2 refer to polyvinyl acetate emulsion, acrylate polymer emulsion, and styrene-acrylic emulsion, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com