Synthesis of poly-alpha olefin and use thereof.

A technology of olefins and oligomers, which is applied in the field of lubricant compositions and can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

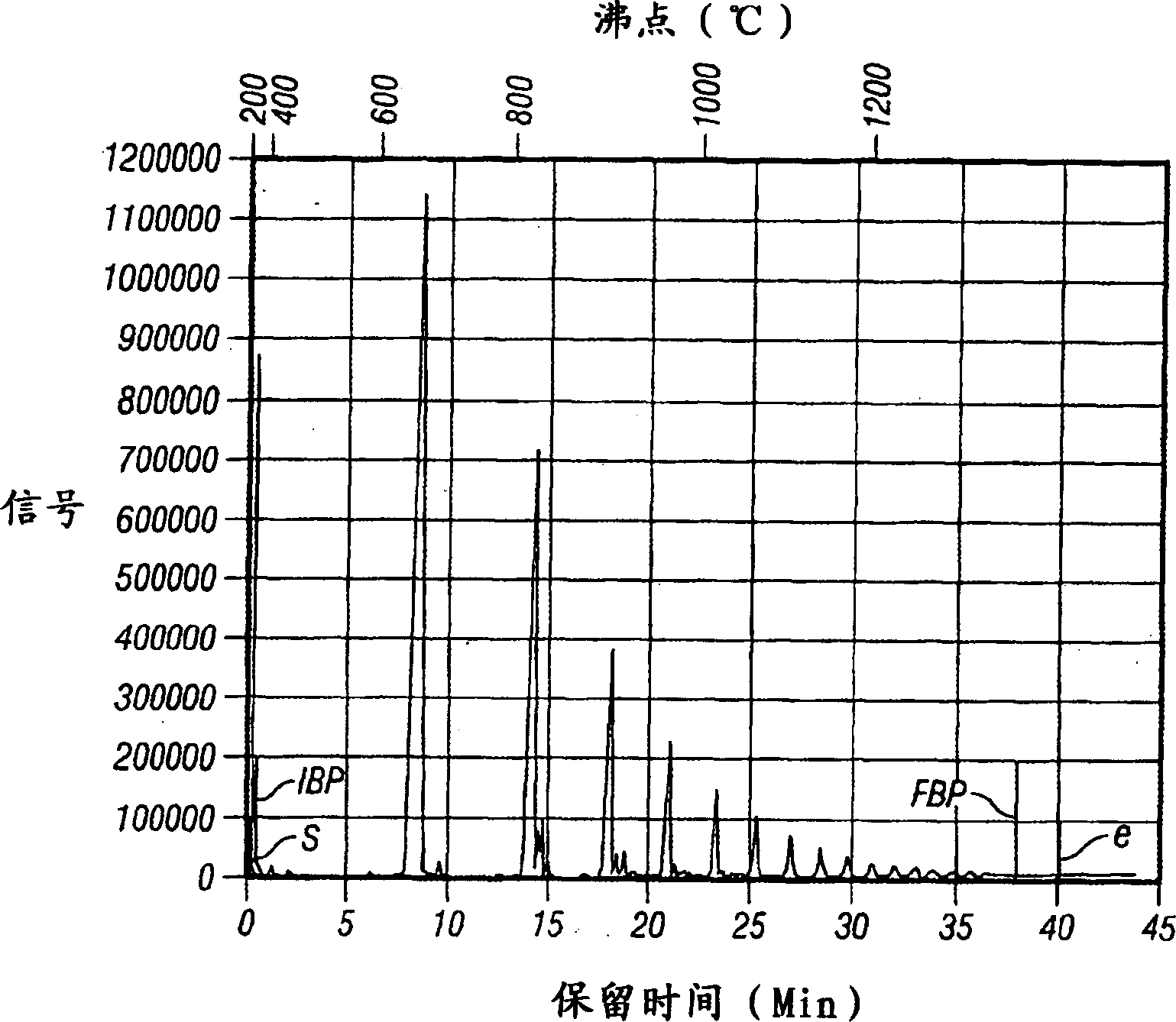

[0085] A 120ml pressure reaction vial with a magnetic stirring bar was completely evacuated and then blown with argon. Then, 10 ml of anhydrous toluene (distilled with potassium treatment) and 10 ml of 1-tetradecene (dried over 5A molecular sieves) were added to the bottle. At 40° C., 4 ml of a 3.3 M methylaluminoxane solution in toluene was added to the reaction flask and stirred for 15 minutes. Then inject 4ml 6.2×10 into the bottle - 3 M's dichlorobis(cyclopentadienyl) zirconium in toluene to start the reaction. The temperature of the reaction system was controlled within ±1°C by a constant temperature bath. After 1 hour, 50 ml of 10% aqueous HCl was added to the reaction flask to stop the reaction, and the resulting mixture was stirred for 2 hours. The organic layer was then separated and further washed twice with 50 ml of deionized water. Subsequently, the toluene solvent was removed from the organic layer in a rotary evaporator. Analysis of the product mixture by hi...

Embodiment 2

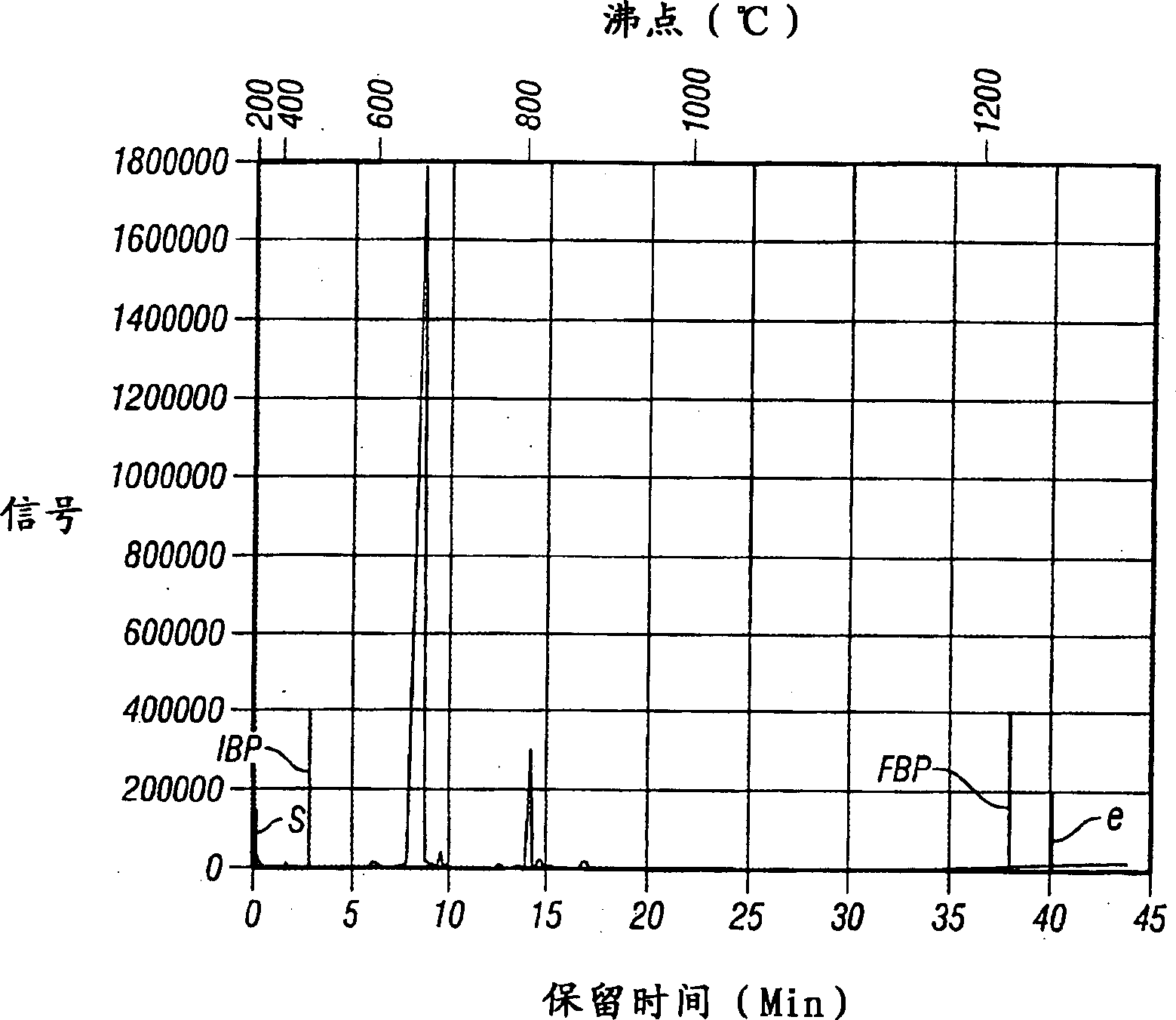

[0087] The procedure was essentially the same as in Example 1, except that the reaction was carried out at 60°C. The oligomer yield was 86%. The oligomer contains about 60% dimers, 23% trimers, 8% tetramers, 4% pentamers and 5% higher oligomers.

Embodiment 3

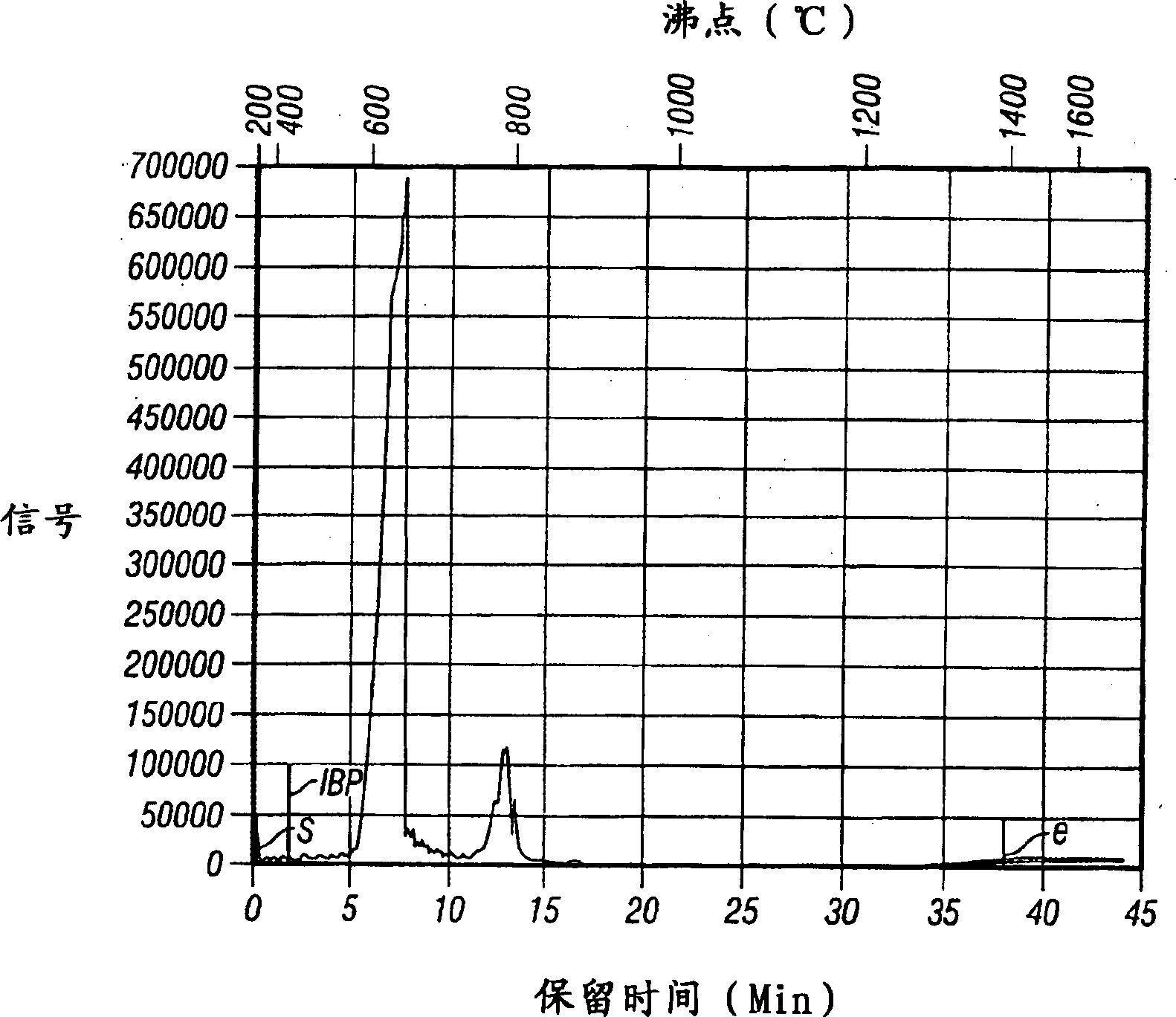

[0089] The procedure was essentially the same as in Example 1, except that the reaction was carried out at 60°C and 2 ml of 3.3 M methylalumoxane in toluene was used. The oligomer yield was 87%. The oligomer contains approximately 68% dimers, 20% trimers, 7% tetramers, 3% pentamers and 2% higher oligomers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com