Sea-tangle edible fiber and its making method

A technology of dietary fiber and production method, which is applied in the improvement field of comprehensive utilization engineering, can solve the problems of serious environmental pollution, complex technological process, unfavorable human health, etc., achieves considerable yield, improves bleaching effect, and is beneficial to post-treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

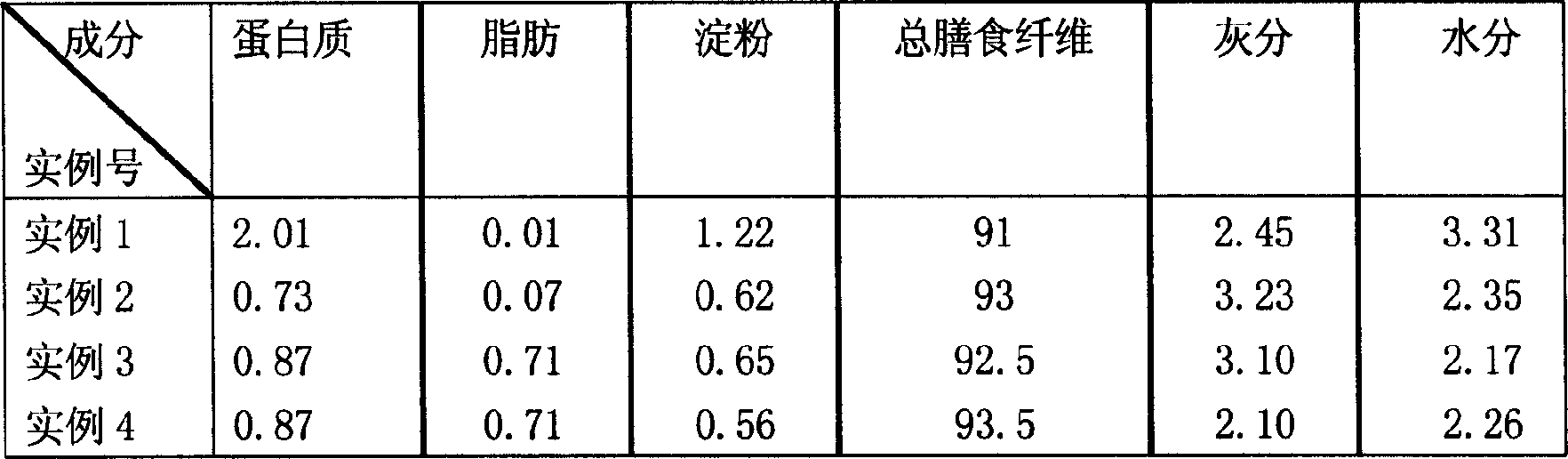

Examples

Embodiment 1

[0029] Embodiment 1: 1000m of alginate plant discharge 3Add 10% calcium chloride solution to the turbid glue pool of seaweed residue until the seaweed residue is flocculated, and collect the seaweed residue flocs with a centrifuge. Take 20 kg of collected wet kelp slag flocs and put them into a stirring reaction tank, add 100-120 kg of water and 1500 g of hydrochloric acid, heat to 30-60°C, stir for 2-3 hours to decalcify, centrifuge with a centrifuge, and collect the kelp Slag is solid; repeat again (add 100-120 kg of water and 1500 g of hydrochloric acid, heat to 30-60°C, stir for 2-3 hours to decalcify), rinse with water until the pH value of the kelp slag glue is neutral, and then centrifuge to obtain kelp Slag solid. Put the solid into the stirred reaction tank again, add 100-120 kg of water and 100-120 g of sodium carbonate, heat it to 45-55 ° C in the stirred reaction tank, keep it warm for 2-3 hours to become black liquor, and then wash the black liquor with water. s...

Embodiment 2

[0030] Embodiment 2: Get 20 kg of wet kelp slag collected by flocculation according to Embodiment 1 and put it into a stirring reaction tank, add 120-140 kg of water and 270-660 g of concentrated hydrochloric acid, heat to 40-65 ° C, and stir for 3-4 hours, centrifuge and collect the kelp slag solid; repeat again (add 120-140 kg of water and 270-660 g of concentrated hydrochloric acid, heat to 40-65 ° C, stir for 3-4 hours to decalcify), and wash with water until neutral, leave Experience kelp slag solid. Put the solid into the stirred reaction tank again, add 110-130 kg of water and 90-110 g of sodium carbonate, heat it to 40-50 ° C in the stirred reaction tank, keep it warm for 3-3.5 hours, and then wash off the black liquor with water to pH The value is neutral, and the filter cake is taken by centrifugal dehydration; then add 120-160 kg of water, 50-85 g of stabilizer sodium phosphate, and 1 kg of bleaching agent H to the filter cake 2 o 2 , bleach at 85-95°C for 2.5-3.5...

Embodiment 3

[0031] Example 3, put 20 kg of wet kelp slag collected by flocculation according to Example 1 into a stirring reaction tank, add 100-120 kg of water and 300-600 g of concentrated hydrochloric acid, heat to 50-70°C, and stir for decalcification for 3-6 hours, centrifuge to collect the kelp slag solid; repeat (add 100-120 kg of water and 300-600 g of concentrated hydrochloric acid, heat to 50-70°C, stir for 3-6 hours to decalcify) twice, and wash with water until neutral, Centrifuge to get kelp slag solid. Put the kelp slag solid into the stirring reaction tank again, add 120-140 kg of water and 50-70 g of sodium carbonate, heat it to 55-75 °C in the stirring reaction tank, keep it warm for 3-5 hours, and then wash off the black liquor with water until the pH value is neutral, centrifugal dehydration, then add 130-160 kg of water and 70-130 g of stabilizer sodium sulfate, and (1 kg of bleach) H 2 o 2 , bleach at 90-100°C for 4-7 hours. After a bleaching, continue to carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion force | aaaaa | aaaaa |

| Expansion force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com