Process for preparing poly-diallyldimethyl ammonium chloride

A technology of dimethyl diallyl ammonium chloride and purification agent, which is applied in the field of preparation of polydimethyl diallyl ammonium chloride, and can solve the problems of waste of water resources, heavy environmental pollution, and heavy workload , to protect the environment, improve cleaning efficiency, save energy and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

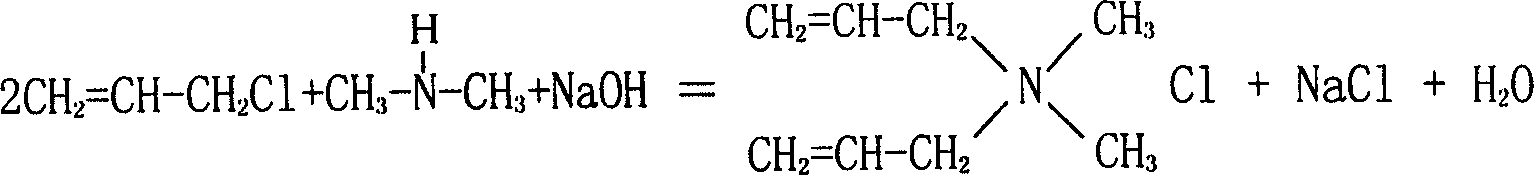

Method used

Image

Examples

Embodiment 1

[0027] Put 245Kg of industrial chloropropene in the reaction kettle, add 50Kg of water containing 50g of purifying agent, and the purifying agent is 4%Na 2 CO 3 , 4% EDTA-2Na equal volume mixed solution (molar ratio is 3.5: 1), the addition of scavenger in water is 0.1%, stirring and mixing for half an hour, after clarification and stratification, put the water layer. If the interface is dirty, wash it again according to the above method.

[0028] Mix 4% sodium fluoride solution and 4% sodium diethylenetriaminepentaacetate solution in equal amounts (9.4:1 molar ratio) to prepare a catalyst.

[0029] Add 100g of catalyst to 168.8Kg of 40% dimethylamine aqueous solution, under normal temperature, drop 150Kg of dimethylamine and 40% NaOH aqueous solution into chloropropene, in the whole dropping process, under the protection of nitrogen, keep stirring, the highest The temperature does not exceed 45°C. After the dropwise addition was completed, the temperature was raised to 50-...

Embodiment 2

[0031] Get 25Kg of DADMAC prepared above, add 5Kg of pure water and stir evenly, add initiator APS 5g (made into 20% aqueous solution), place at normal temperature, along with the carrying out of polymerization reaction, system temperature rises gradually, keep polymerization temperature to be 50 After 10 hours at °C, a viscous solution of PDADMAC was obtained. With 0.5M sodium chloride as solvent, the measured limit viscosity is 1.24, according to η ∞ =3.982×10 -4 m 0.566 Calculation, M=1.49×10 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com