Li-Si-O-based high dielectric constant ceramic materials and method for synthesizing same

A high dielectric constant, ceramic material technology, applied in ceramics, fixed capacitor dielectrics, fixed capacitor components and other directions, can solve the problem of high loss and other problems, and achieve the effect of reducing energy consumption, reducing sintering temperature, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

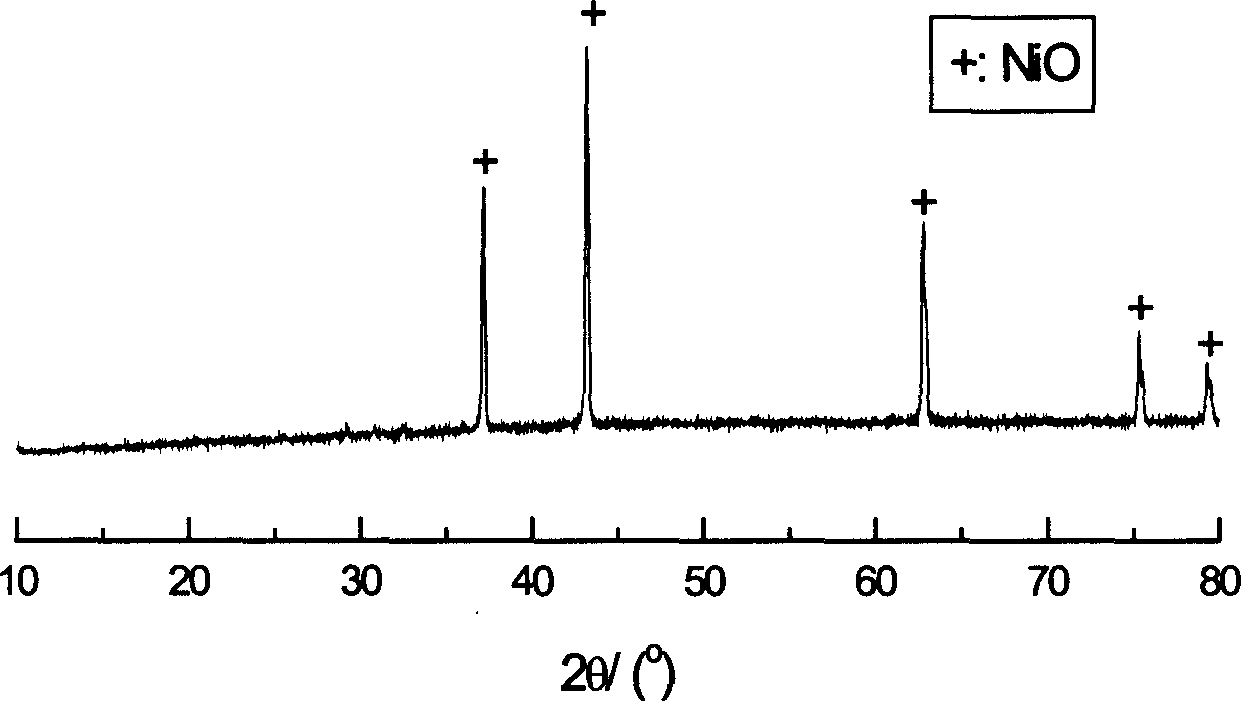

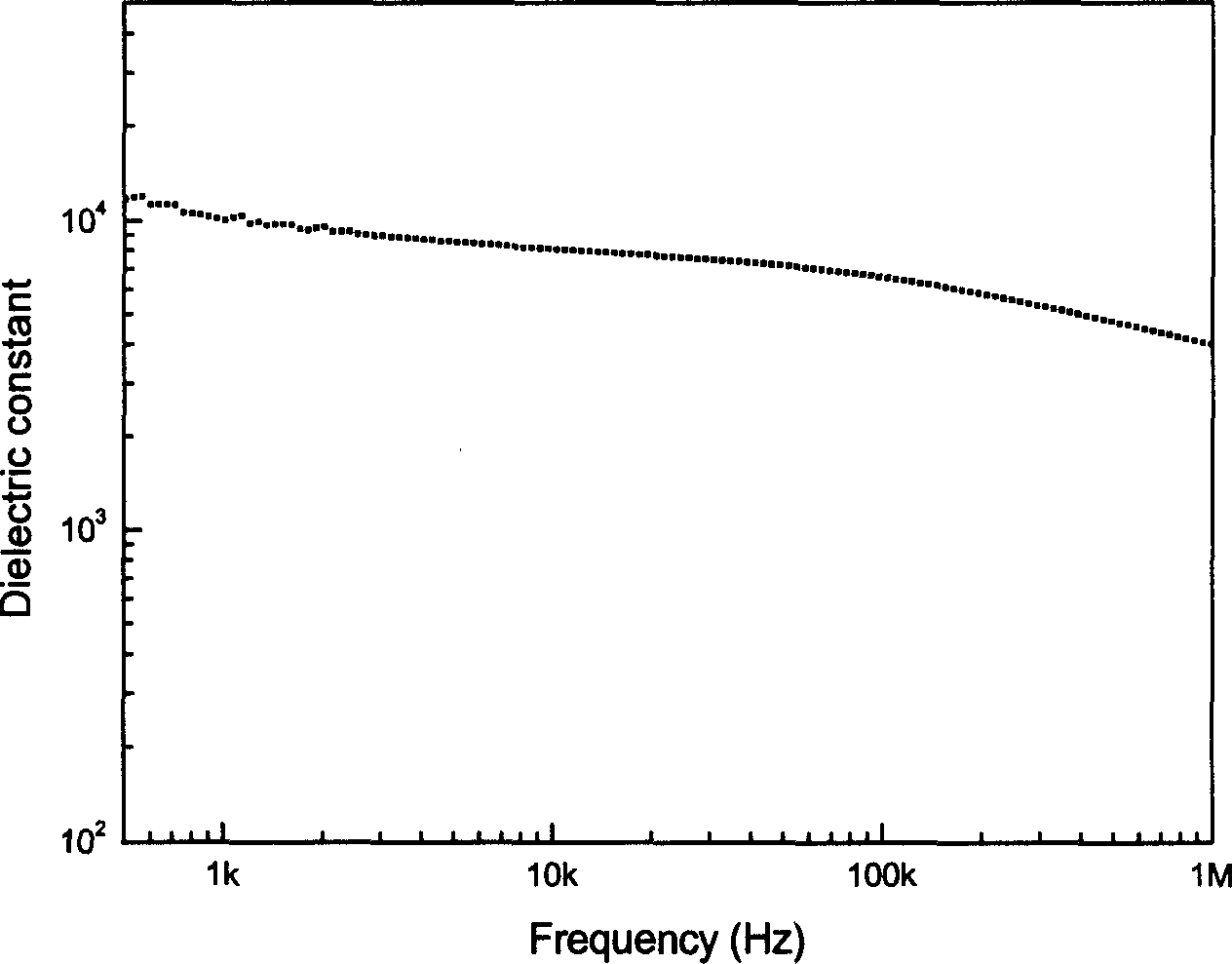

[0027] Weigh 0.005mol LiNO 3 , 0.965mol Ni(NO 3 ) 2 Dissolve in 500ml of deionized water to form a Li / Ni mixture. Slowly add the Ni / Li mixture to 0.5mol / L ammonium bicarbonate solution to fully react, wash the precipitate, and then Dry at 100°C to obtain Li-doped nano-scale NiO precursor powder. Disperse this composite powder in distilled water to form a suspension, and slowly add ethyl orthosilicate solution (containing about 0.03mol SiO 2 ), adjust the pH of the solution to about 7.5 to hydrolyze the ethyl orthosilicate and coat it on the Ni / Li powder to form a coating layer. The composite powder is filtered, washed, dried, granulated, dry pressed at 3MPa, and sintered in air at 1250°C for 2.5 hours to obtain Li 0.005 Si 0.03 Ni 0.965 O ceramic materials. XRD test shows that the phase is basically NiO phase. At room temperature, the relative dielectric constant ε=10200 (1kHz), and the dielectric constant does not change much with frequency. The microstructure picture of the mate...

Embodiment 2

[0029] The ethyl orthosilicate solution (about 0.15mol SiO 2 ), adjust the pH of the solution to about 3.5 to hydrolyze the ethyl orthosilicate to form a transparent sol. Weigh 0.01mol LiNO 3 , 0.84mol Ni(NO 3 ) 2Dissolve it in 400ml deionized water to form a Li / Ni mixture. Slowly add the Ni / Li mixture to the sol. Adjust the pH to about 7.2 to make it further gelatinize. Pre-fired at 300°C to obtain Li-doped nano-scale NiO precursor powder. The pre-fired powder was granulated, dry pressed at 4MPa, and sintered in air at 1250°C for 2.5 hours to obtain Li 0.01 Si 0.15 Ni 0.84 O ceramic materials. XRD test shows that most of the phase is NiO phase with a small amount of Ni 2 SiO 4 phase. At room temperature, the relative dielectric constant ε=1890 (10kHz), and the dielectric loss tanδ=0.42. Such as Figure 4 , Figure 5 Shown.

Embodiment 3

[0031] Weigh 0.01mol LiNO 3 , 0.79mol Ni(NO 3 ) 2 Dissolve it in 400ml deionized water to prepare a Li / Ni mixture. Slowly add the Ni / Li mixture to 0.8mol / L ammonium carbonate solution to fully react, wash the precipitate, and then Drying at ℃ to obtain Li-doped nano-scale NiO precursor powder. Disperse this composite powder in distilled water to form a suspension, and slowly add ethyl orthosilicate solution (about 0.20mol SiO 2 ), adjust the pH value of the solution to about 7.8 to hydrolyze the ethyl orthosilicate and coat the Ni / Li powder to form a coating layer. The composite powder is filtered, washed, dried, granulated, dry pressed at 3MPa, and sintered in air at 1250°C for 2.5 hours to obtain Li 0.01 Si 0.2 Ni 0.79 O ceramic materials. XRD test shows that most of the phase is NiO phase with a small amount of Ni 2 SiO 4 phase. At room temperature, the relative dielectric constant ε=870 (10kHz), and the dielectric loss tanδ=0.35. And in the temperature range of -10℃-170℃, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com