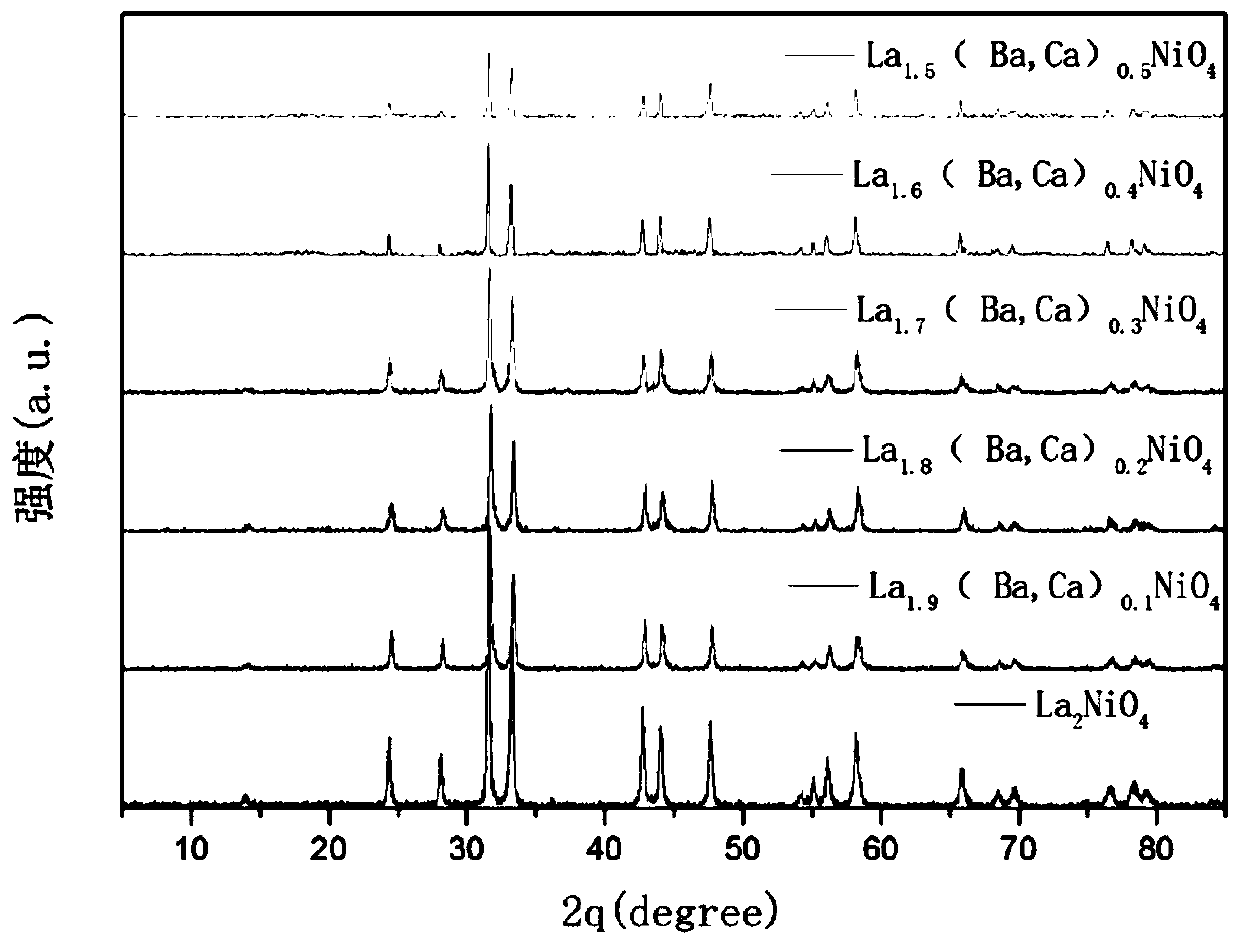

A barium-calcium co-doped substitution la 2 nio 4 Giant dielectric ceramic and its preparation method

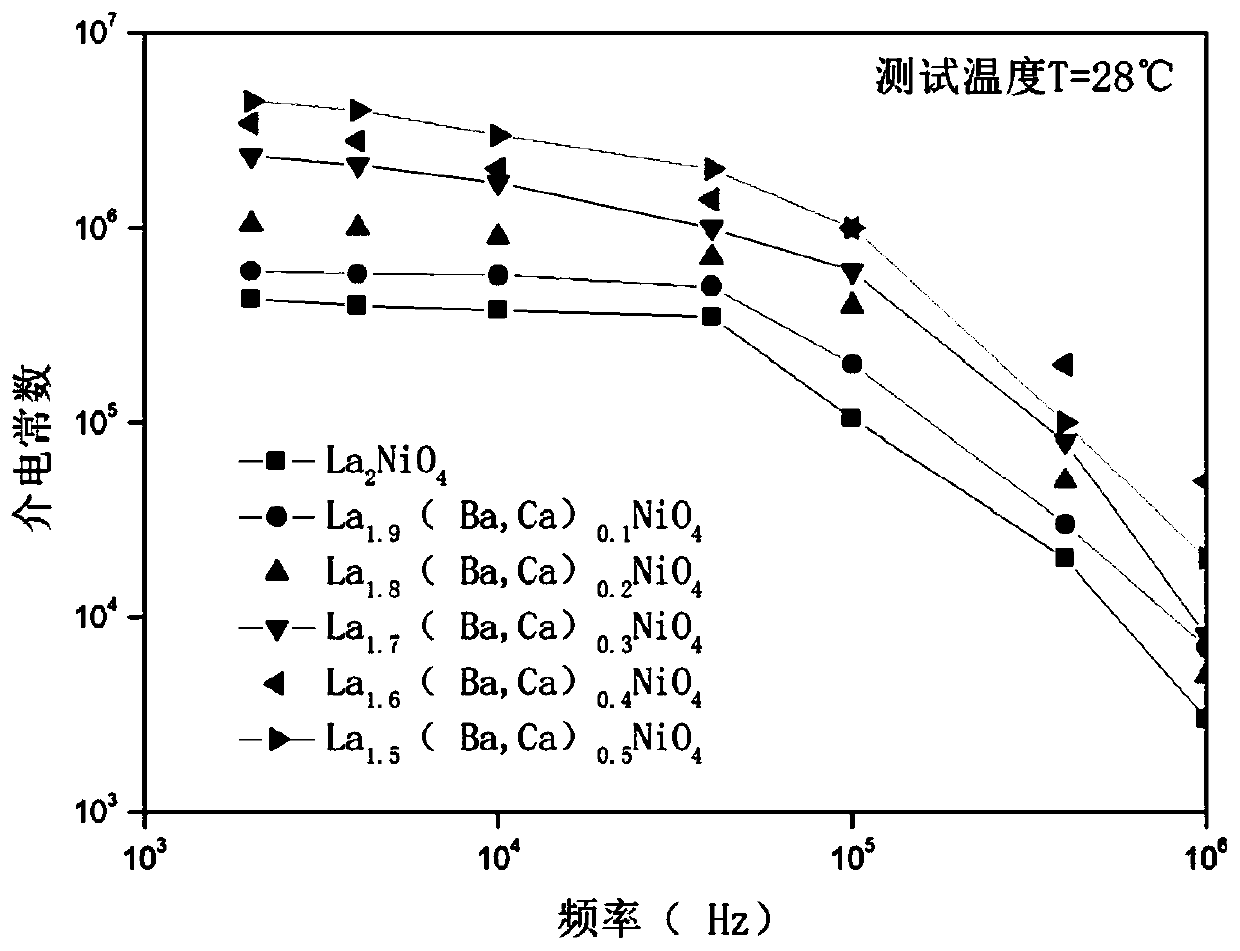

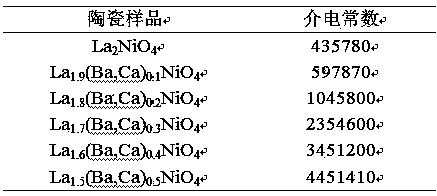

A co-doping and giant dielectric technology is applied in the field of barium-calcium co-doping substitution of La2NiO4 giant dielectric ceramics and its preparation, which can solve the problem of poor frequency stability of dielectric constant, narrow temperature range of dielectric constant, and high dielectric constant. Constant and other issues, to achieve the effect of good temperature stability, easy preparation, high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of mixed powder: Take 9.286g of lanthanum oxide, 0.296g of barium carbonate, 0.15g of calcium carbonate, and 2.241g of nickel oxide in a ball mill jar, add 10ml (0.45wt%PVB+0.45wt% oleic acid) and 5ml Dehydrated ethanol is placed in a planetary ball mill for ball milling for 24 hours, and after drying, it is passed through a 150-mesh sieve to obtain a mixed powder;

[0072] (2) Preparation of pre-fired La 1.9 (Ba,Ca) 0.1 NiO 4 powder: put the mixed powder in step (1) in an alumina crucible, then place the aluminum crucible in a high-temperature tube furnace and pre-fire it at 1100°C for 3 hours to obtain pre-fired La 1.9 (Ba,Ca) 0.1 NiO 4 Powder;

[0073] (3) Secondary ball milling: put the pre-burned powder in a ball milling tank, add 15ml of absolute ethanol, put it in a planetary ball mill for 18 hours, and pass through a 150-mesh sieve after drying to obtain La 1.9 (Ba,Ca) 0.1 NiO 4 Powder;

[0074] (4) Granulation: to 2g La 1.9 (Ba,Ca) 0....

Embodiment 2

[0079] (1) Preparation of mixed powder: Take 8.797g of lanthanum oxide, 0.592g of barium carbonate, 0.3g of calcium carbonate, and 2.241g of nickel oxide in a ball mill jar, add 10ml (0.45wt% PVB+0.45wt% oleic acid) and 5ml Dehydrated ethanol is placed in a planetary ball mill for ball milling for 24 hours, and after drying, it is passed through a 150-mesh sieve to obtain a mixed powder;

[0080] (2) Preparation of pre-fired La 1.8 (Ba,Ca) 0.2 NiO 4 powder: put the mixed powder in step (1) in an alumina crucible, then place the aluminum crucible in a high-temperature tube furnace and pre-fire it at 1100°C for 3 hours to obtain pre-fired La 1.8 (Ba,Ca) 0.2 NiO4 Powder;

[0081] (3) Secondary ball milling: put the pre-burned powder in a ball milling tank, add 15ml of absolute ethanol, put it in a planetary ball mill for 18 hours, and pass through a 150-mesh sieve after drying to obtain La 1.8 (Ba,Ca) 0.2 NiO 4 Powder;

[0082] (4) Granulation: to 2gLa 1.8 (Ba,Ca) 0.2 N...

Embodiment 3

[0087] (1) Preparation of mixed powder: Take 8.308g of lanthanum oxide, 0.888g of barium carbonate, 0.45g of calcium carbonate, and 2.241g of nickel oxide in a ball mill jar, add 10ml (0.45wt%PVB+0.45wt% oleic acid) and 5ml Dehydrated ethanol is placed in a planetary ball mill for ball milling for 24 hours, and after drying, it is passed through a 150-mesh sieve to obtain a mixed powder;

[0088] (2) Preparation of pre-fired La 1.7 (Ba,Ca) 0.3 NiO 4 powder: put the mixed powder in step (1) in an alumina crucible, then place the aluminum crucible in a high-temperature tube furnace and pre-fire it at 1100°C for 3 hours to obtain pre-fired La 1.7 (Ba,Ca) 0.3 NiO 4 Powder;

[0089] (3) Secondary ball milling: put the pre-burned powder in a ball milling tank, add 15ml of absolute ethanol, put it in a planetary ball mill for 18 hours, and pass through a 150-mesh sieve after drying to obtain La 1.7 (Ba,Ca) 0.3 NiO 4 Powder;

[0090] (4) Granulation: to 2g La 1.7 (Ba,Ca) 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com