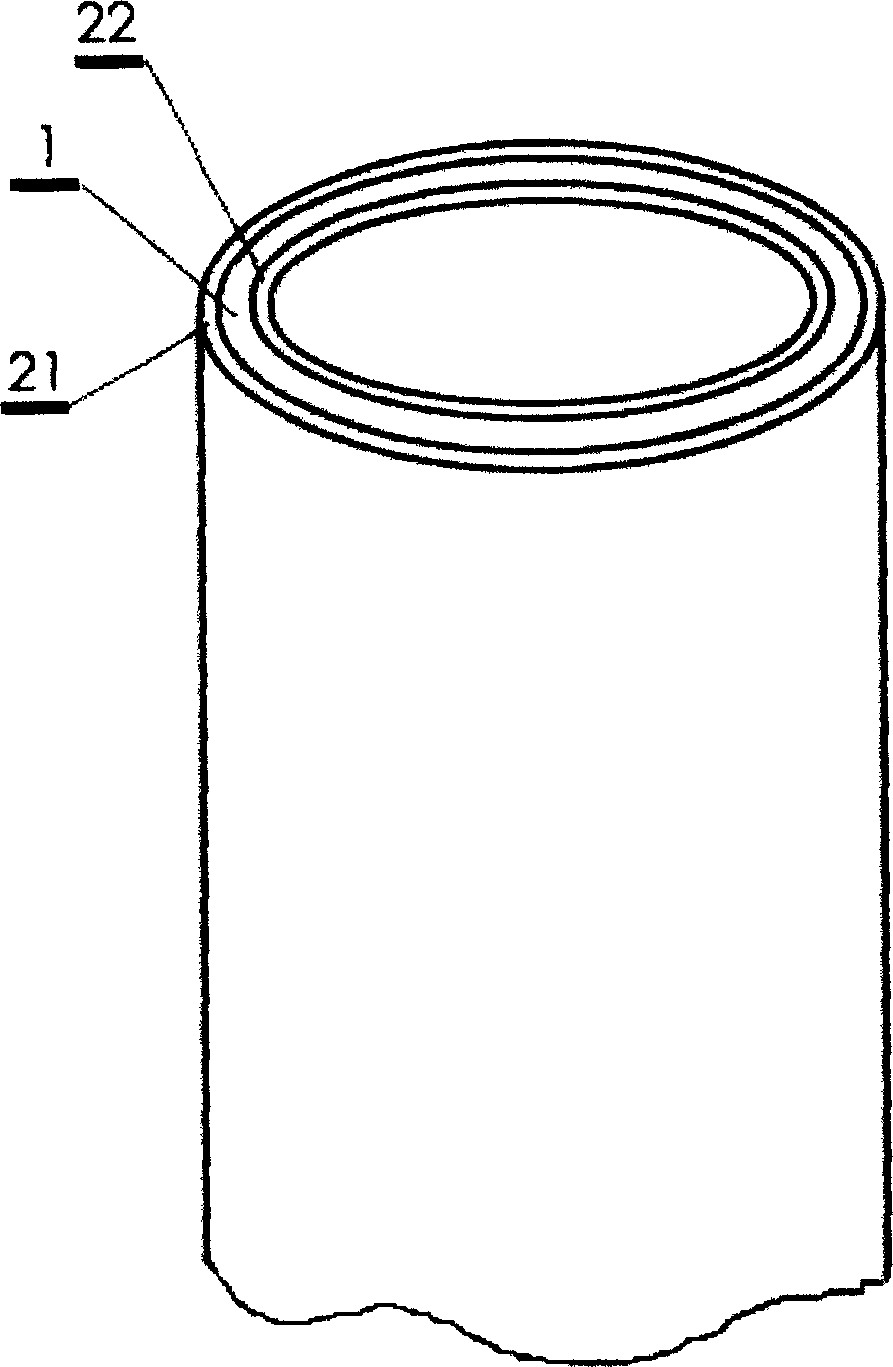

Multipurpose and multilayer coextruded plastic composite pipe

A multi-layer co-extrusion, composite pipe technology, applied in the direction of pipes, rigid pipes, layered products, etc., can solve the problem of poor tensile strength, impact strength, poor processing performance, aggravated cost rise and strength reduction, high antistatic cost problem, to achieve the effect of good combustion resistance, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pipe diameter: 160 mm, working pressure 0.8 MPa, pipe wall thickness 6.2 mm, core layer thickness 3.2 mm, outer skin layer and inner skin layer thickness 1.5 mm.

[0040] The composition of the cortex material is as follows:

[0041] 100 parts of PVC and ABS (1:1) blended, 0.1 part of oxidized polyethylene wax, 2 parts of compound stabilizer, 0.2 part of stearic acid, 0.5 part of calcium stearate, 1 part of decabromodiphenyl ether, chlorinated polystyrene 2 parts of ethylene, 3 parts of acrylate polymer, 16 parts of acetylene carbon black, 3 parts of calcium carbonate.

[0042] The composition of the core material is as follows:

[0043] 100 parts of polyvinyl chloride, 0.1 part of oxidized polyethylene wax, 2.5 parts of compound stabilizer, 0.3 part of stearic acid, 0.5 part of calcium stearate, 1 part of decabromodiphenyl ether, 3 parts of chlorinated polyethylene,

[0044] Acrylic polymer (ACR) 6 parts, talcum powder or calcium carbonate 15 parts.

[0045] Chlorinat...

Embodiment 2

[0047] The pipe diameter is 160 mm, the working pressure is 1.0 MPa, the pipe wall thickness is 7.7 mm, the core layer is 4.7 mm thick, and the inner and outer skin layers are 1.5 mm thick.

[0048] The composition of the cortex material is as follows:

[0049] 100 parts of polyvinyl chloride and ABS (1:0.5) resin blend, 0.5 parts of oxidized polyethylene wax, 4.5 parts of composite stabilizer, 1 part of stearic acid, 1.5 parts of calcium stearate, 3 parts of decabromodiphenyl ether, 5 parts of chlorinated polyethylene, 10 parts of acrylate polymer, 12 parts of conductive carbon black.

[0050] The composition of the core material is as follows:

[0051] 100 parts of polyvinyl chloride, 0.3 parts of oxidized polyethylene wax, 5 parts of compound stabilizer, 1 part of stearic acid, 1.2 parts of calcium stearate, 3 parts of decabromodiphenyl ether, 6 parts of chlorinated polyethylene, acrylates Polymer (ACR) 11 parts, talcum powder or calcium carbonate 30 parts.

Embodiment 3

[0053] The pipe diameter is 160 mm, the working pressure is 1.25 MPa, the pipe wall thickness is 9.5 mm, the core layer is 6.5 mm thick, and the inner and outer skin layers are 1.5 mm thick.

[0054] The composition of the cortex material is as follows:

[0055] 100 parts of polyvinyl chloride, 1 part of oxidized polyethylene wax, 7 parts of compound stabilizer, 2 parts of stearic acid, 2.5 parts of calcium stearate, 5 parts of decabromodiphenyl ether, 10 parts of chlorinated polyethylene, acrylate polymerization 15 parts, graphite powder 30 parts, talcum powder 10 parts.

[0056] The composition of the core material is as follows:

[0057] 100 parts of polyvinyl chloride, 0.5 parts of oxidized polyethylene wax, 7 parts of compound stabilizer, 2 parts of stearic acid, 2.5 parts of calcium stearate, 6 parts of decabromodiphenyl ether, 10 parts of chlorinated polyethylene, acrylates 15 parts of polymer, 40 parts of talcum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com