Nano-beam resonator with field effect pipe manufactured using sacrifice layer corrosion technology

A field effect tube and resonator technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effects of cost reduction, good promotion and application range, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

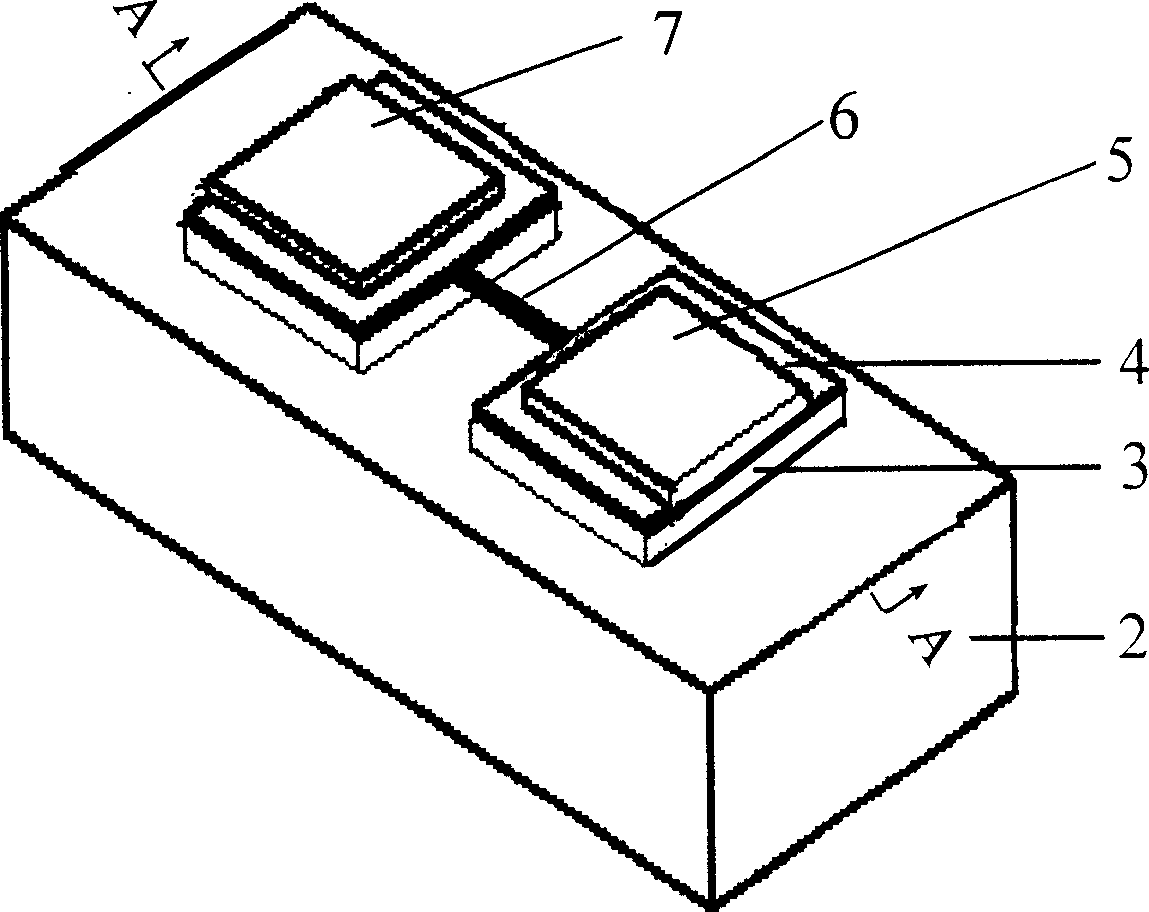

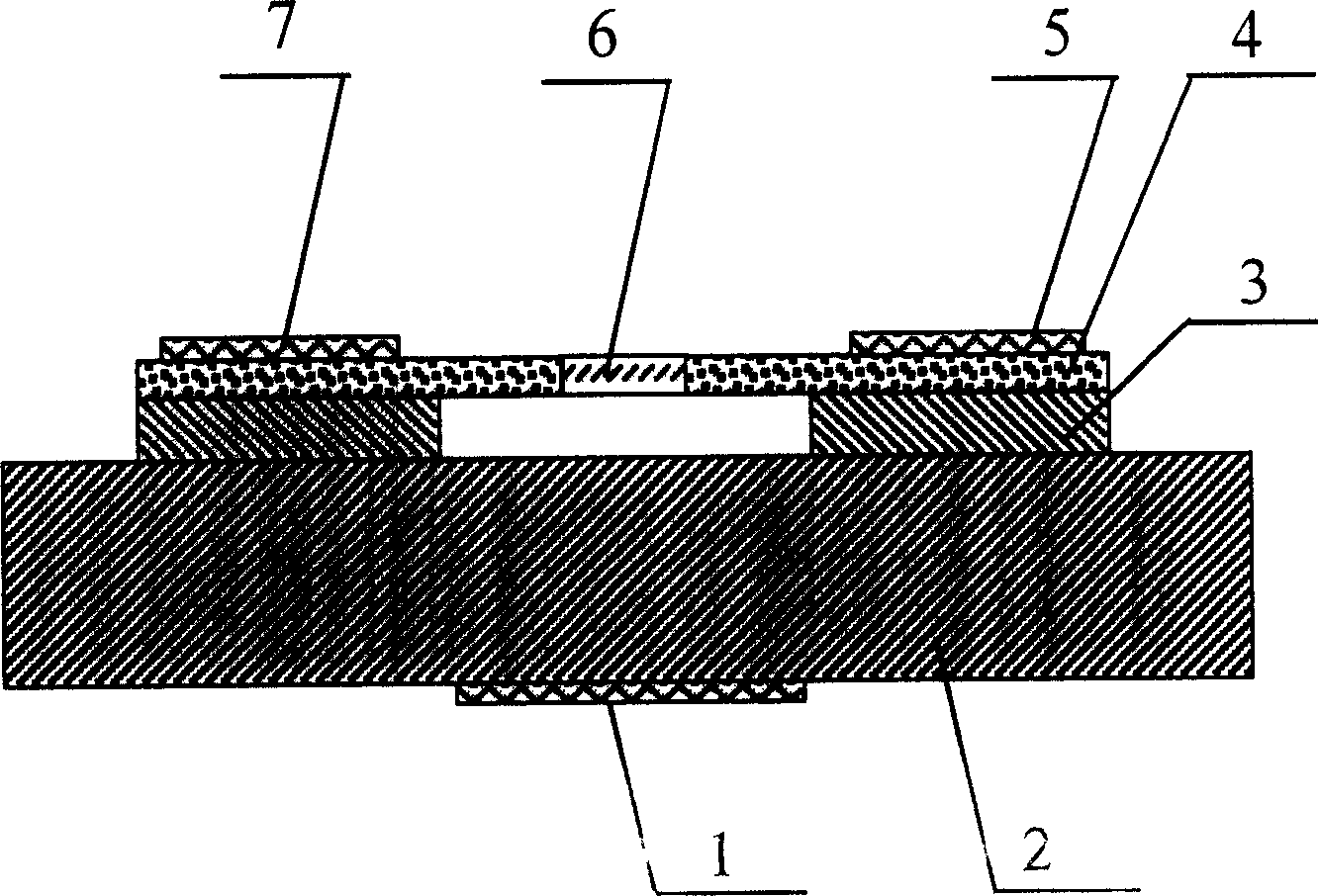

[0009] refer to figure 1 , figure 2 , the present invention uses SOI silicon epitaxial wafers as raw material and is manufactured by micro-nano machining process. Cantilever nano-beam 6 is manufactured using photoresist as a mask, using Reactive Ion Etching (Reactive Ion Etching) process to etch silicon dioxide insulating layer 3 between silicon layer 4 and SOI, and then using sacrificial layer etching technology to etch the nano-beam The silicon dioxide insulating layer 3 beneath the beam 6 is hollowed out. The side walls of the cantilever nano-beam 6 fabricated by this process are vertical. The manufacture of P-i-P or N-i-N channel structure is to use photoresist as a mask to photoetch out the region to be doped, and then perform boron or phosphorus implantation to form P + or N + area.

[0010] The specific production process is described as follows:

[0011] 1. Using SOI silicon epitaxial wafers as raw materials, they are cut and cleaned to make standard silicon epi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com