Process for preparing streptoverticillum transglutaminase

A technology for bacterial glutamine and glutamine is applied in the field of manufacturing technology of Streptomyces cinnamonis glutaminyltransferase, and can solve the problems of many separation steps, low yield, high price and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

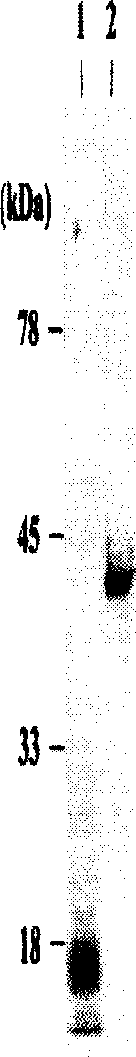

[0020] Identification of a transglutaminase from Streptomyces cinnamomi. S. cinnamomi was purchased from the Institute of Microbiology, Chinese Academy of Sciences. Ultrafiltrate 20ml to 1ml supernatant of S. cinnamona fermentation broth and centrifuge, take 50ul of it, add 10μl 6XSDS sample buffer, boil at 100°C for 10min, and load the sample on 12% SDS-PAGE. After the electrophoresis is completed, take the PVDF membrane, wet it with methanol, place the electrophoresed SDS-PAGE gel on the PVDF membrane, and put it into the electrotransfer tank. The PVDF membrane is on the anode side, and the SDS-PAGE gel is on the cathode side. , 100 volts, electrotransfer is completed in one hour. Remove the PVDF membrane and place it in phosphate buffer at 4°C overnight to let the enzyme renature. The next day, add CBZ-Gln-Gly and hydroxylamine to the above buffer as substrates, CBZ-Gln-Gly decomposes into CBZ and Gln-Gly-hydroxylamine, CBZ is colored, and it can be seen that the colored ...

Embodiment 2

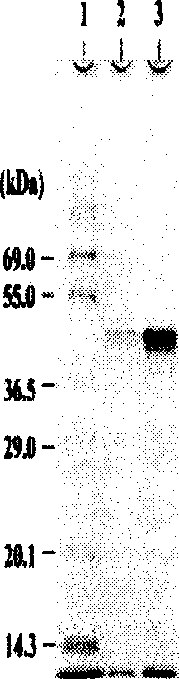

[0022] Isolation and purification of transglutaminase from Streptomyces cinnamomi. S. cinnamomum was cultured in the semi-solid medium of Gowell's slant. When the colonies were formed, they were inoculated in the Erlenmeyer flask containing 1000ml of fermentation medium. The components of the medium were: glycerol 20g / L, yeast extract 2g / L, peptone 50g / L, MgSO 4 .7H 2 O 2g / L, K 2 HPO 4 .3H 2 O 2g / L, pH7.0 (sterilized at 121°C for 20min), 30°C, 210r / Min, cultured for 5 days. Collect the fermented liquid and centrifuge at 4°C for 15 minutes (6000rpm), take the supernatant, ultrafilter with an ultrafilter at 4°C, and ultrafilter to 200ml, add 200ml of 10mM, pH7.0 phosphate buffer, and continue to ultrafilter to 200ml. Then add 200ml of 10mM, pH7.0 phosphate buffer, and continue ultrafiltration to 100ml. On the 100ml ultrafiltrate, the hydroxyapatite separation medium column that has been balanced with 10mM, pH7.0 phosphate buffer solution was first washed with 10mM, pH7.0 p...

Embodiment 3

[0024] Preparation of Polyclonal Antibody to Streptothrix cinnamomi Transglutaminase.

[0025] Choose 4-6 high-quality big-eared white rabbits, feed them adaptively, and observe disease-free for one week. Rabbits were routinely immunized with BCG. A certain amount of antigen (Streptrichum cinnamomi transglutaminase) SDS-PAGE, stained with Coomassie brilliant blue (or 250MmKCl staining), cut off the target band, ground the glue in a mortar with liquid nitrogen, and The glue was mixed with adjuvant (1:1), and then ground into a paste to immunize rabbits. One week after the time-based immunization, 1-2mg antigen / bird. The prepared gel was 1 mg antigen / 1 g gel.

[0026] 1. Booster immunization after two weeks (or three weeks): 1-2 mg of antigen per mouse.

[0027] 2. Booster immunization one week later: 1-2 mg of antigen per mouse. Double expansion method can be used to detect the presence or absence of antibody production.

[0028] 3. The third booster immunization is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com