Large scale in situ preparation method of ternary NaV6O15 single crystal nanometer needle

A single crystal nanometer and in-situ preparation technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as powerlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

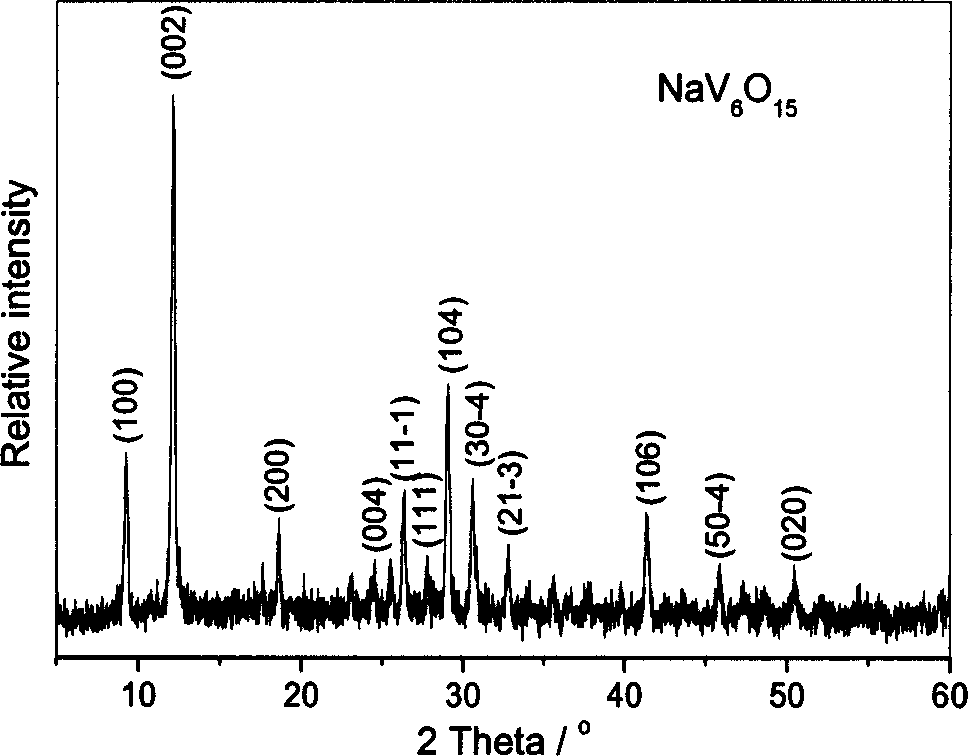

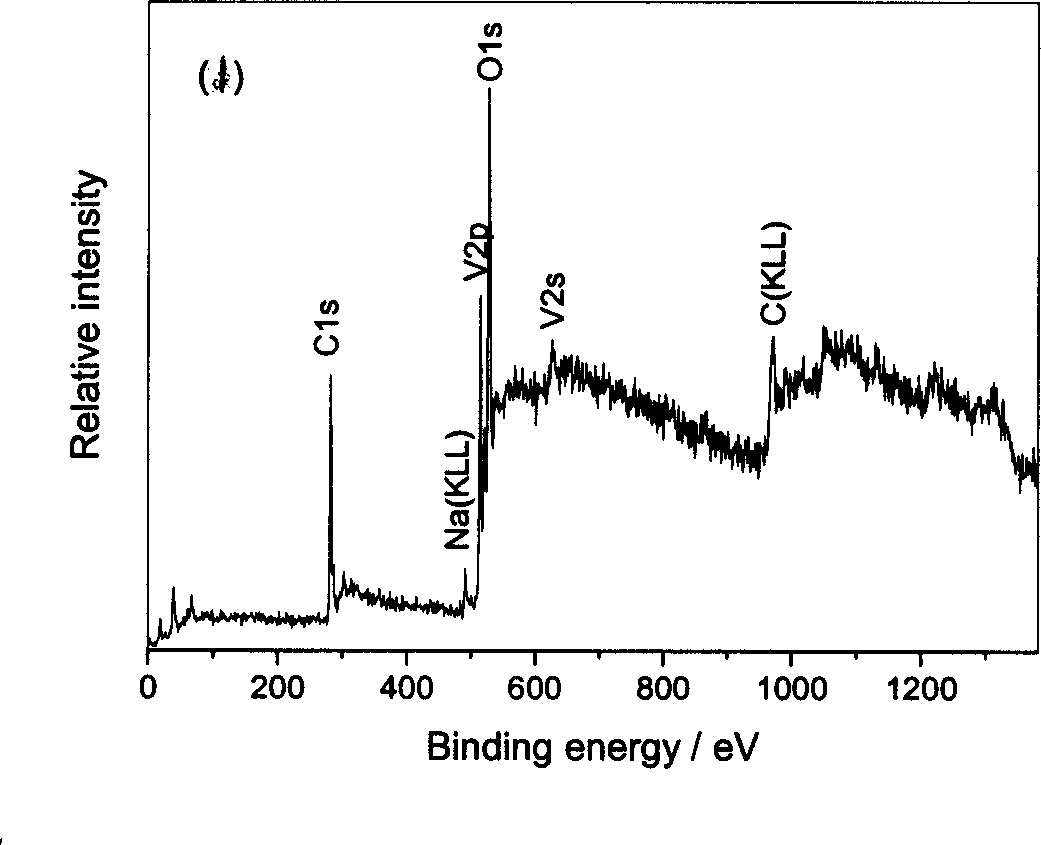

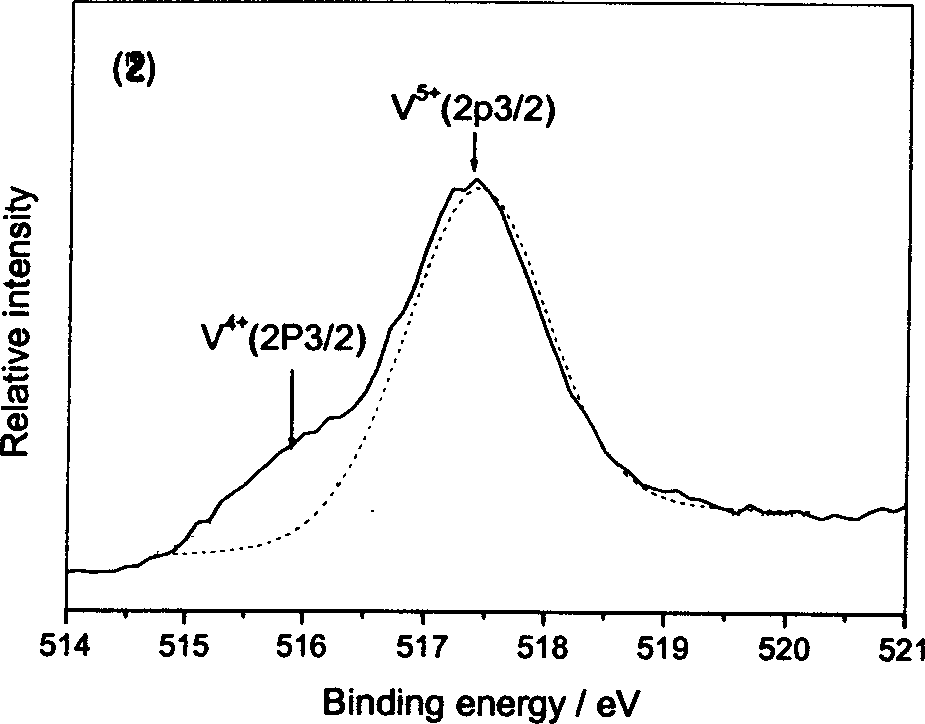

[0029] with V 2 o 5 Powder and PSMA-Na are raw materials, HF is catalyst, and 0.91g V 2 o 5 Add powder and 5mL 4M HF solution to 70mL 3.0gL -1 PSMA-Na aqueous solution, after stirring for 2 minutes. The resulting suspension was transferred to a 100 ml hydrothermal kettle. After sealing, hydrothermally treat at 180±5°C for 24 hours, then cool naturally to room temperature. After the reaction, the pH of the solution was about 3.5, and the yellow-green reaction product was collected and washed five times with distilled water and absolute ethanol, respectively. Finally, one-dimensional three-dimensional NaV was obtained after vacuum drying at 80±5°C for 6 hours. 6 o 15 Single crystal nanoneedle products. The XRD spectrum, X-ray photoelectron energy spectrogram, scanning electron micrograph and transmission electron micrograph of the obtained product are shown in figure 1 , figure 2 , image 3 and Figure 4 .

Embodiment 2

[0031] In order to examine the effect of precursor concentration on the quality of nanoneedles, except the precursor V 2 o 5 Except that the concentrations of the powder and PSMA-Na are different, other experimental conditions such as the temperature and time of the hydrothermal treatment, the concentration of HF, etc. are exactly the same as in Example 1. It was found that: when V 2 o 5 The concentration of powder and PSMA-Na is too high, greater than 25 and 15gL respectively -1 When the concentration is too high and the viscosity is too large, NaV is mainly formed in the solution 6 o 15 mixture of nanoneedles, nanowires and particles, and is difficult to disperse; on the contrary, if V 2 o 5 The molarity of powder and PSMA-Na is too low, below 1 and 0.1gL respectively -1 When, the NaV produced by the reaction 6 o 15 Metastable due to too little supersaturation to form NaV 6 o 15 nanoneedles. When NaV 6 o 15 When the concentration is between the two, NaV can be ...

Embodiment 3

[0033] In order to test V 2 o 5 Concentration ratio between powder and PSMA-Na versus NaV 6 o 15 Effect of nanoneedle quality and yield, except V 2 o 5 Except that the concentration ratio between the powder and PSMA-Na is different, other experimental conditions such as the concentration of HF, the temperature and time of hydrothermal reaction, the temperature and time of vacuum drying, etc. are exactly the same as in Example 1. It was found that: when V 2 o 5 When the concentration ratio between powder and PSMA-Na is less than 1, due to the high concentration of PSMA-Na in the precursor solution, the resulting product is mainly NaV 6 o 15 The gel of nanoneedles and PSMA-Na polymer cannot be well dispersed. Conversely, if V 2 o 5 When the concentration ratio between powder and PSMA-Na is greater than 10, because the PSMA-Na concentration in the precursor solution is too low, V 2 o 5 Powder does not fully convert to NaV 6 o 15 , the product is mainly composed of V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com