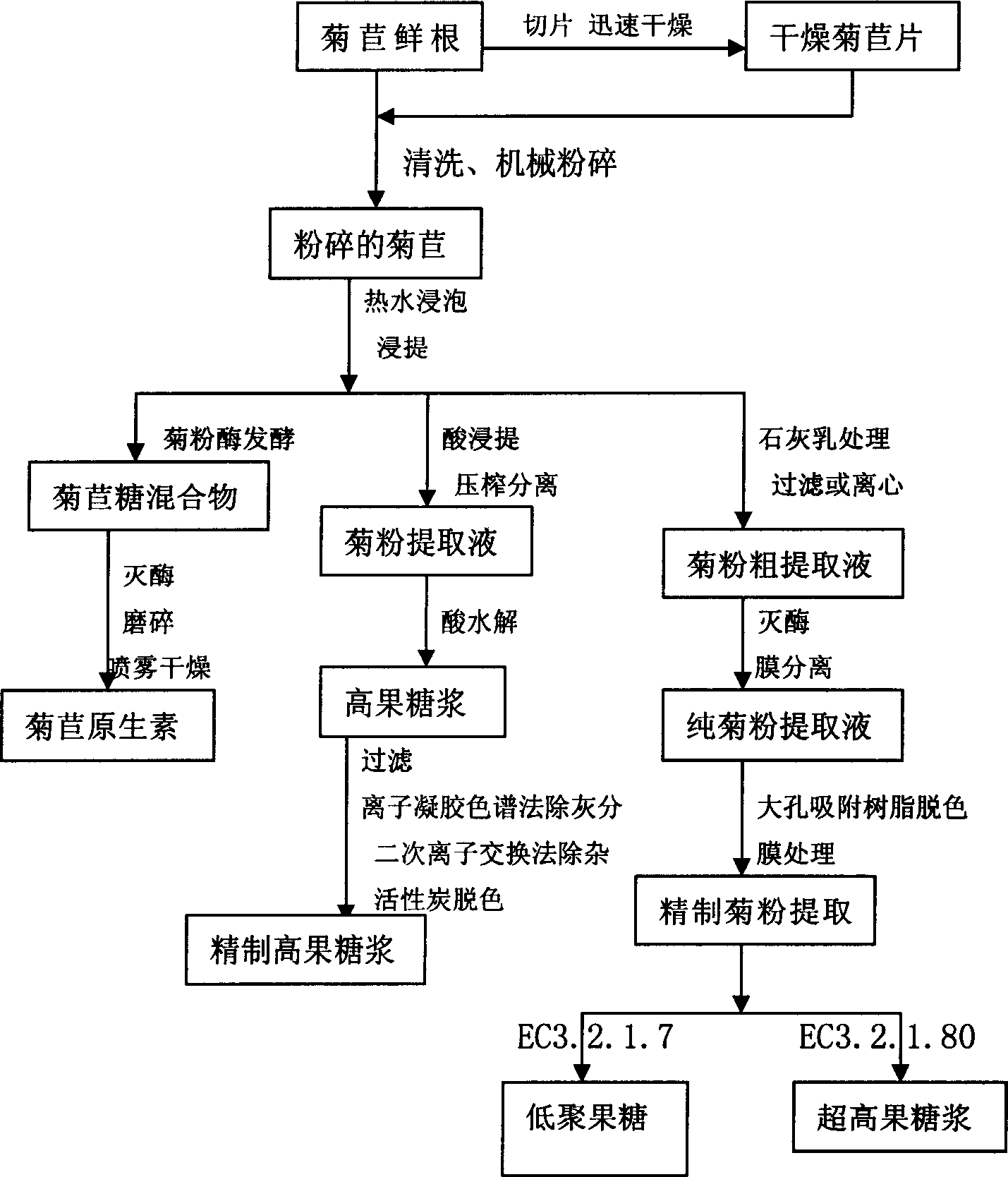

Technique for producing fruit sugar by using chicory to carry out hydrolysis

A chicory and fructose technology, which is applied in the production of sugar, sugar production, fructose, etc., can solve the problems of difficult to meet market demand and low fructose output, and achieve the effect of reducing production cost and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] 4. Preparation of high fructose syrup:

[0054] (1) Acid hydrolysis: the hydrolysis raw material obtained by the above 2 (2) is placed in a hydrolysis reactor, and the temperature is controlled at about 120-160° C. for 1-10 minutes to obtain a hydrolyzate. Filter to obtain crude fructose extract. In this reaction, the macromolecular fructose is completely hydrolyzed into monofructose at a pH value between 3-6 and without enzymes. The acid hydrolyzate contains 1-5% sugars, 8.7% impurities such as salts and pigments, and 4.7% protein, so further desalination and decolorization are required.

[0055] (2) Decolorization and desalination of high fructose syrup

[0056] ①The hydrolyzate is first filtered by ion exchange gel chromatography (DOWEX Monsophere) to remove ash, ②Then two ion exchange resin methods are used to remove protein: first use a strong acidic cation exchange resin (such as Dowex88) to elute at a temperature greater than 70°C , and then through a weakly a...

Embodiment 1

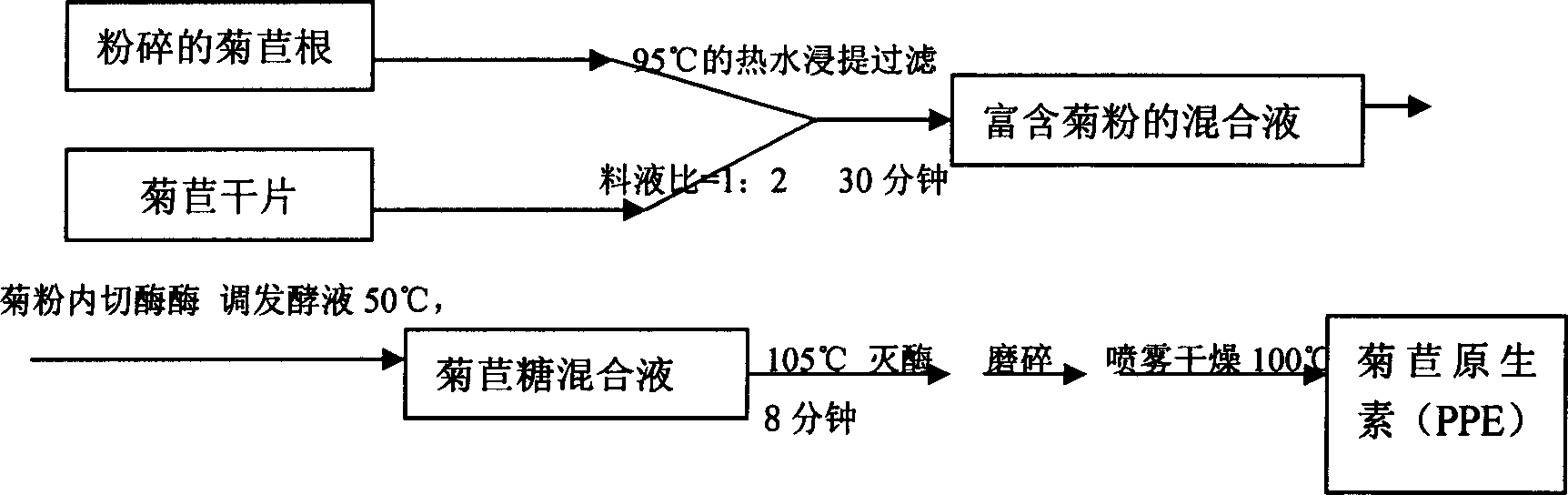

[0073] Embodiment 1: the production of raw element PPE

[0074] see figure 2 , carry out according to the preparation method of above-mentioned raw element, 10 kilograms of pulverized fresh chicory roots or 7 kilograms of chicory dry slices are leached and filtered in hot water with a temperature of 95 ° C, the ratio of solid to liquid = 1: 2 ~ 3, and the time is 30 minutes. That is to obtain a mixed solution rich in inulin; then adjust the fermented solution to pH 4.0 with endo-inulinase, temperature 50°C, sugar content 25%, time 12 hours; Spray-dried under the condition of ℃ to obtain 6.313 kg of brown-yellow extract chicory progenin (PPE).

example 2

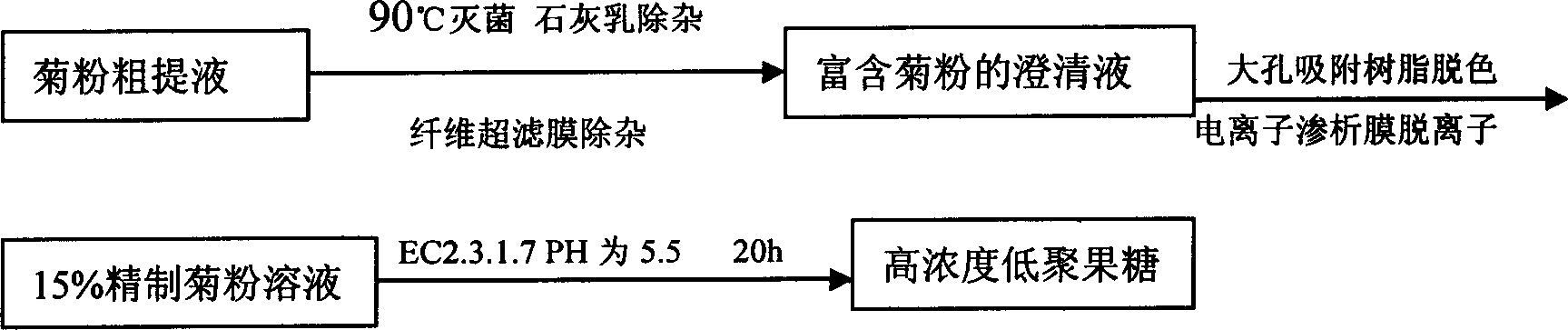

[0075] Example 2: Production of high concentration oligosaccharides

[0076] see image 3According to the preparation method of the above-mentioned oligosaccharides, 10 kg of chicory fresh roots or dried chicory slices are leached and filtered in hot water at a temperature of 95 ° C, and after three times of countercurrent leaching and one slag washing process, the crude inulin extract is obtained , Cool the obtained inulin crude extract to 45°C, sterilize at 90°C and add lime milk to remove impurities, adjust the pH to 13.5, pass in carbon dioxide to remove excess calcium ions, and filter under reduced pressure, plate and frame filter machine or centrifuge to separate the precipitated impurities from the filtrate to obtain refined inulin extract;

[0077] Select a hollow fiber inorganic ultrafiltration membrane with a pore size of 0.2um to completely remove bacteria, solidified and water-soluble proteins, colloids, pigments and other insoluble substances, and decolorize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com