Environmental protection method for extracting lead in waste storage battery

A technology for waste batteries and batteries, which is applied in the field of lead extraction, can solve the problems of large equipment investment, high smelting temperature, environmental pollution, etc., and achieve the effect of high value and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

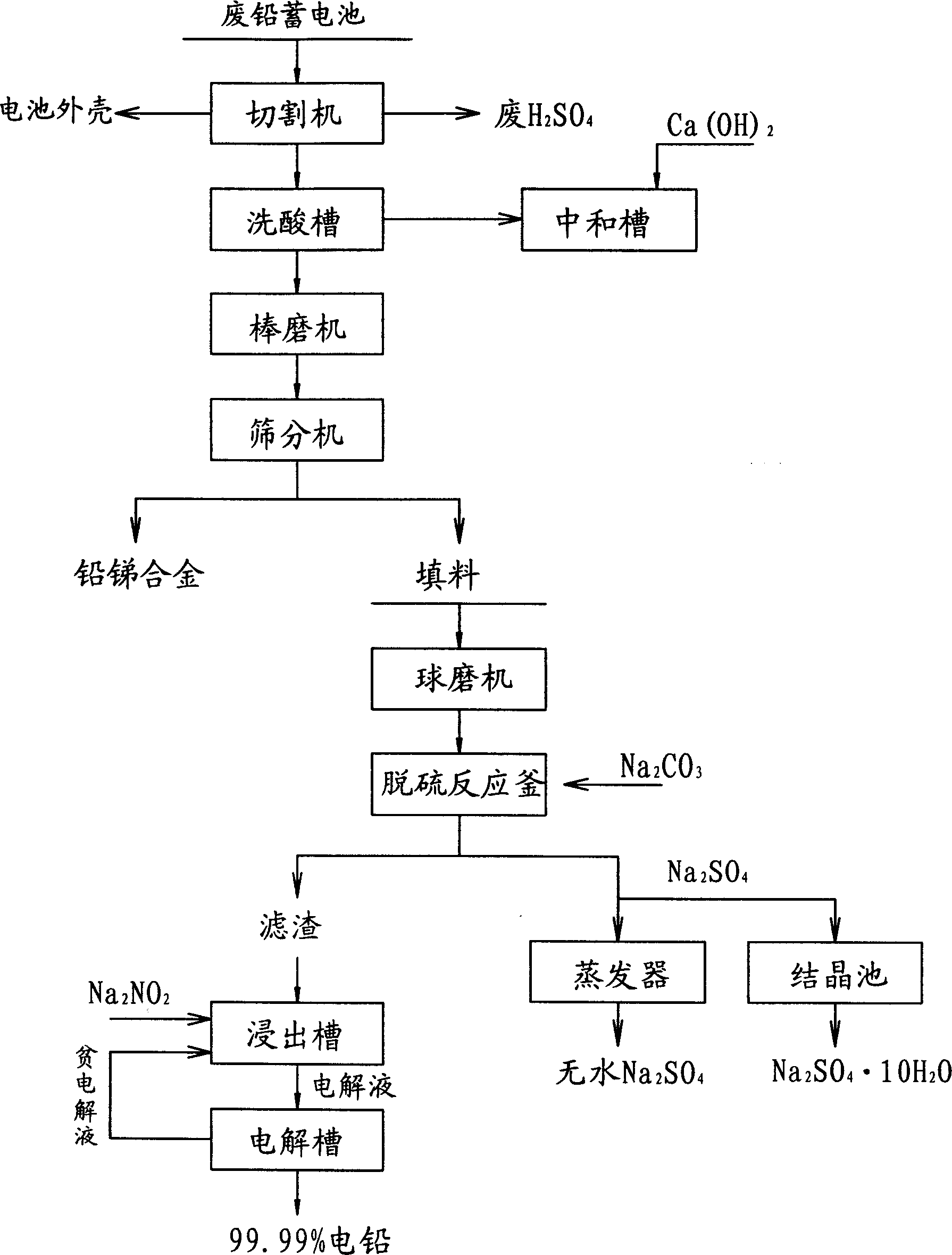

[0020] Embodiment one: see figure 1

[0021] Such as figure 1 As shown, this embodiment includes three parts: pretreatment desulfurization, electrolytic deposition and desulfurization agent recovery.

[0022] 1. Pretreatment desulfurization

[0023] 1.1 After the battery is poured acid, the cutting machine cuts off the upper cover and pours out the pole plate. The pole plate is sent to the rod mill after acid washing, and the grid plate and filler are obtained by screening after the rod mill;

[0024] 1.2 The grid plate is directly melted and cast into a finished alloy ingot. After the filler is finely ground into a ball mill to a size larger than 80 mesh, it enters a desulfurization reactor for desulfurization, and a desulfurizer and a reducing agent are added for desulfurization and reduction transformation. The desulfurizer is sodium carbonate and the reducing agent is sodium nitrite, the reaction formula is

[0025]

[0026]

[0027] 1.3 After the filler ...

Embodiment 2

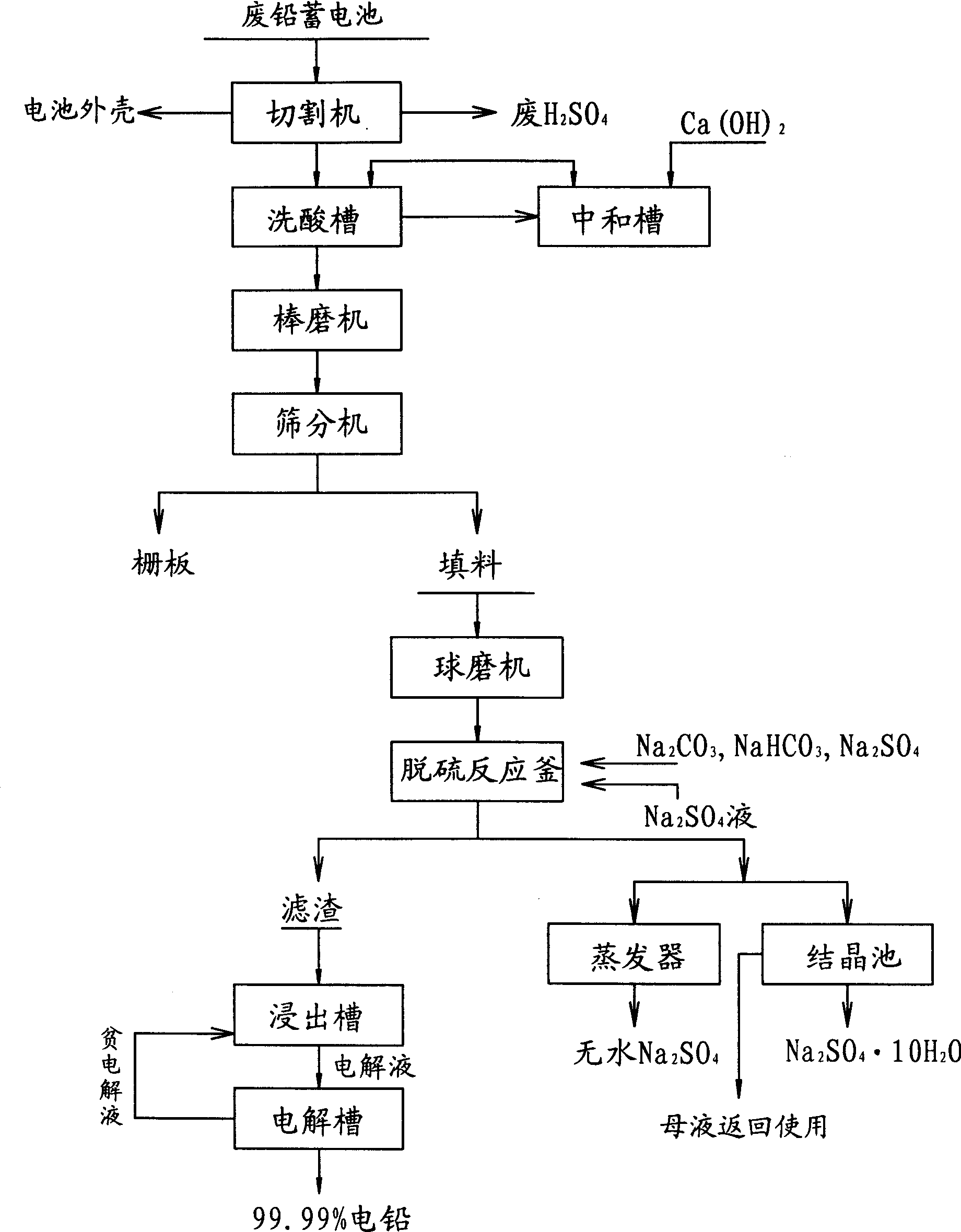

[0038] Embodiment two: see figure 2

[0039] The difference from Example 1 is that in the pretreatment desulfurization stage, sodium sulfite is used as the reducing agent, and the reaction formula is:

[0040]

[0041]

[0042] Others are the same as the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com