Preparation method of low temperature phase barium metaborate nano powder

A technology of barium metaborate and nanopowder, which is applied in the direction of borate, boron oxide, etc., can solve the problems of optical inhomogeneity, large temperature gradient, and difficulty in growing large-sized crystals, and achieve easy control of process parameters, The preparation process is simple and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

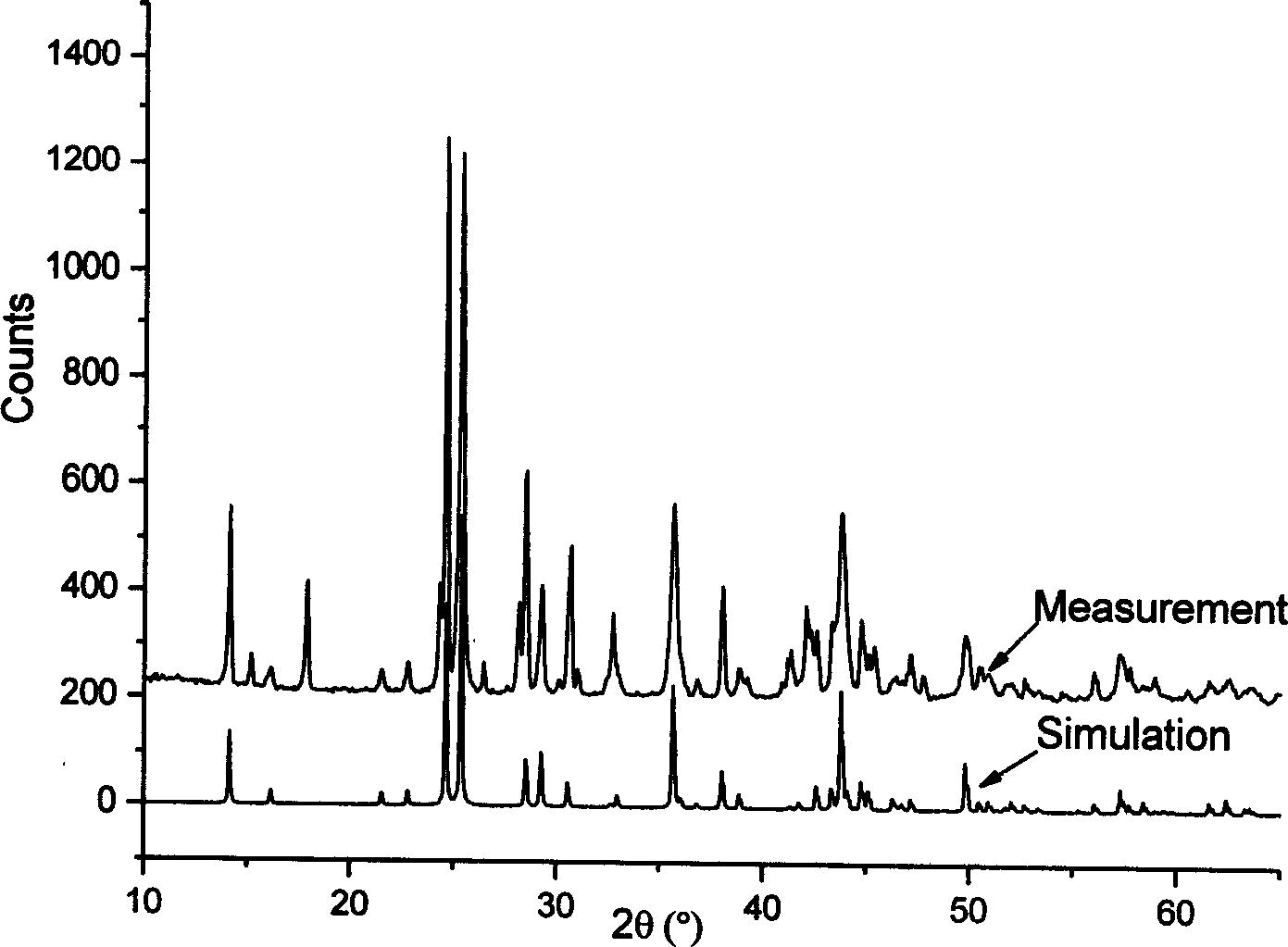

Embodiment 1

[0016] Ba(NO 3 ) 2 and H 3 BO 3 Dissolve in distilled water respectively, the concentrations of barium ions and boron ions are 0.2mol / L and 1.0mol / L respectively, mix these two solutions according to the ion molar ratio of 1:2, and add excess triethanolamine dropwise under full stirring solution (concentration is 3.0mol / L), a white colloidal precipitate is obtained after completion, and the pH value is about 10. Suction filtration, washed twice with distilled water, washed twice with absolute ethanol, dried at 110°C for 6 hours, ground, then placed in a high temperature furnace, calcined at 700°C for 8 hours to obtain BBO powder with an average particle size of 40 nm.

Embodiment 2

[0018] BaCl 2 and H 3 BO 3 Dissolve in distilled water respectively, the concentrations of barium ions and boron ions are 0.5mol / L and 2.0mol / L respectively, mix the two solutions according to the ion molar ratio of 1:2, and add excess triethanolamine dropwise under full stirring solution (concentration is 3.0mol / L), a white colloidal precipitate is obtained after completion, and the pH value is about 11. Suction filtration, washed twice with distilled water, washed twice with absolute ethanol, dried at 110°C for 6 hours, ground, then placed in a high temperature furnace, calcined at 750°C for 8 hours to obtain BBO powder with an average particle size of 80 nm.

Embodiment 3

[0020] Ba(NO 3 ) 2 and H 3 BO 3 Dissolve in distilled water respectively, the concentrations of barium ions and boron ions are 0.2mol / L and 1.0mol / L respectively, mix the two solutions according to the ion molar ratio of 1:2, and add excess triethylamine dropwise under full stirring. In the amine solution (concentration is 3.0mol / L), a white colloidal precipitate is obtained after completion, and the pH value is about 11. Suction filtration, washed twice with distilled water, washed twice with absolute ethanol, dried at 110°C for 6 hours, ground, then placed in a high temperature furnace, calcined at 700°C for 8 hours to obtain BBO powder with an average particle size of 40 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com