High-Al13 aluminium trichloride polymer crystal and its prepn

A technology of polyaluminum chloride and aluminum chloride, which is applied in the fields of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc. It can solve problems such as poor water solubility, uneven product quality formula and production process , to achieve excellent flocculation effect, wide application area, and reduce water treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

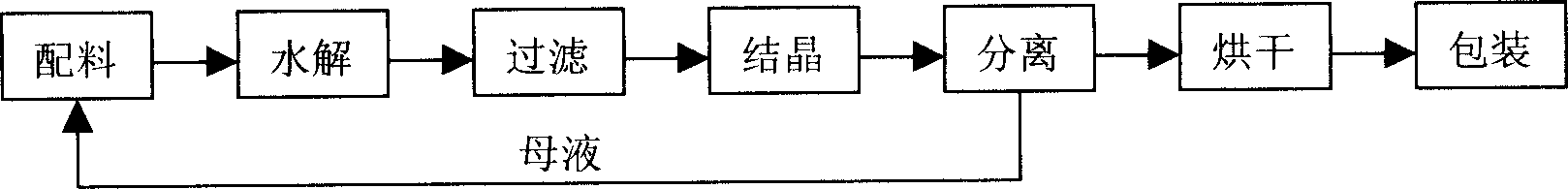

Method used

Image

Examples

Embodiment 1

[0041] Al 13 The starting solution concentration required for crystallization (AlCl 3 The concentration is 0.1mol / kg) and the degree of hydrolysis-polymerization reached (the ratio of aluminum hydroxy to 2.8) determines the proportioning of aluminum foil, crystalline aluminum chloride and water, and the production scale is based on the total weight of reactants of 500kg, and 11.63kg of crystalline chlorine is weighed Aluminum chloride (converted according to the actual purity when the crystalline aluminum chloride is impure), 18.13kg aluminum foil (converted according to the actual purity when the aluminum foil is impure), inject 470.3kg of water into the reaction kettle. Start stirring, add crystalline aluminum chloride into the reaction kettle to dissolve, start the interlayer heating of the reaction kettle, control the reaction temperature to 100°C, add aluminum foil in batches, keep stirring and react for 1 hour, send it to the filter device for heat preservation and filtr...

Embodiment 2

[0043] Al 13 The starting solution concentration required for crystallization (AlCl 3 The concentration is 2.3mol / kg) and the degree of hydrolysis-polymerization reached (ratio of hydroxyaluminum is 0.1) to determine the proportioning of aluminum chips, crystalline aluminum chloride and water, and the production scale is based on the total weight of reactants of 500kg, and 277.1kg of crystals are weighed Aluminum chloride, 1.06kg of aluminum chips (converted according to the actual purity when the aluminum chips are impure), inject 221.9 kg of water into the reactor. Start stirring, add crystalline aluminum chloride into the reaction kettle to dissolve it, start the interlayer heating of the reaction kettle, control the reaction temperature at 40°C, add aluminum scraps in batches, keep stirring and react for 72 hours, send it to the filter device for heat preservation and filtration, and the filtrate Send to the crystallization equipment and freeze and crystallize at 0°C, whe...

Embodiment 3

[0045] Al 13 The initial solution concentration required for crystallization (HCl concentration is 0.1mol / kg) and the degree of hydrolysis-polymerization achieved (ratio of hydroxyaluminum is 2.8) determine the proportioning of aluminum flakes, concentrated hydrochloric acid and water, and the production scale is based on the total weight of reactants 500kg Calculate, weigh 4.89kg concentrated hydrochloric acid (concentration is calculated by 12mol / L, density is calculated by 1.19g / cm 3 Calculate according to the actual concentration when the concentration changes), 6.63kg aluminum flakes (convert according to the actual purity when the aluminum flakes are impure), and inject 488.5kg of water into the reaction kettle. Start stirring, turn on reflux condensed water, add concentrated hydrochloric acid into the reaction kettle, start the interlayer heating of the reaction kettle, control the reaction temperature at 100°C, add aluminum flakes in batches, keep stirring for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com