Method for preparing metal oxide hollow microcapsule

A technology of oxide and hollow micro, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of cumbersome steps, safety and economy, and complicated operation process. The method is simple and easy to control, and the shell component Adjustable, high-efficiency preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

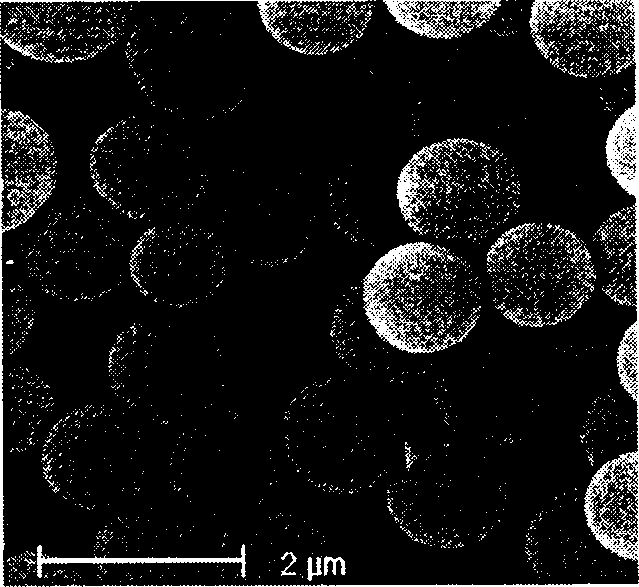

[0033] Mix 1g of hexadecylamine, 100ml of isopropanol, 90ml of distilled water and 1.4ml of ammonia water, stir well at room temperature, then inject 5.8ml of tetraethoxy silicon into the above solution, stop stirring after 30 seconds, and let it stand at room temperature for 1 day , filter the product, wash it with distilled water, dry it and bake it in an air atmosphere at 600°C for 6 hours to remove hexadecylamine, and obtain mesoporous silica microsphere A 1 .

example 2

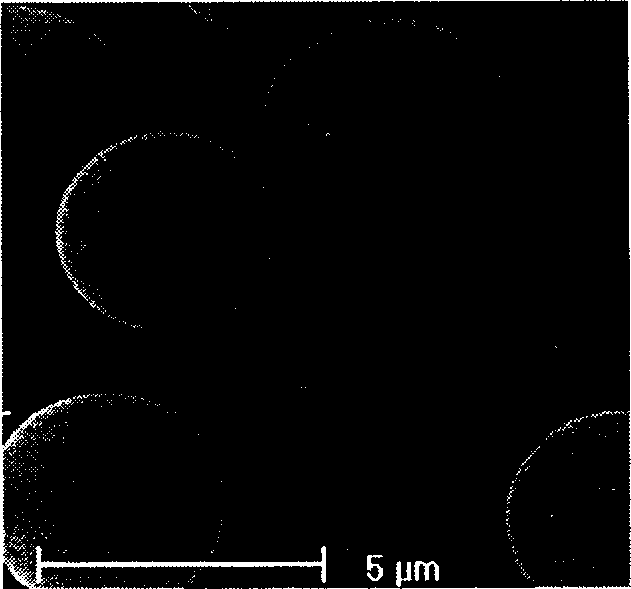

[0035] 1.96g CTAB, 2.32gNa 2 SiO 3 9H 2 O mixed with 17g of distilled water, stirred evenly at room temperature, then injected 1.75ml of ethyl acetate into the above solution, stopped stirring after 30 seconds, and heated the mixed solution after standing at room temperature for 5 hours in an oil bath at 90°C for 50 hours, The product was filtered and washed with distilled water, dried and calcined at 600°C in an air atmosphere for 6 hours to remove CTAB to obtain mesoporous silica microspheres B 1 .

example 3

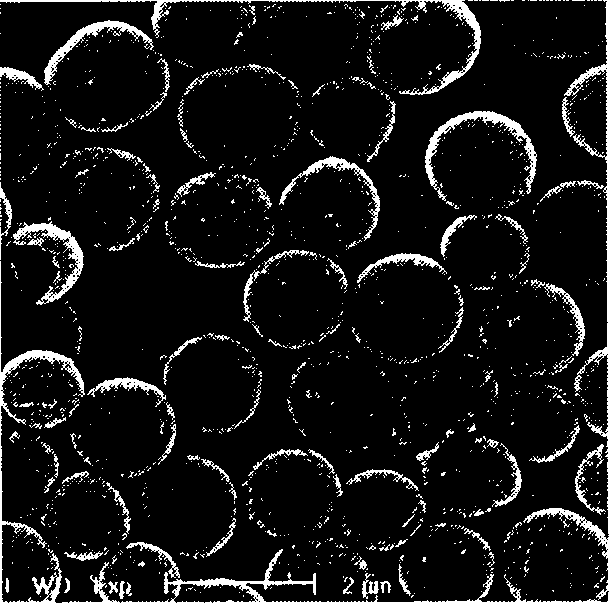

[0037] 0.5g A 1 Immerse in 30ml of 2w.t.% amino silicon ester ethanol solution and stir for 6 hours, wash with ethanol for 1 to 6 times, filter to obtain silica microspheres modified with amino groups in the pores, denoted as A 2 . 0.5g A 1 Immerse in 30ml of 2w.t.% mercaptosilyl ester toluene solution and stir for 6 hours, wash with toluene for 1-6 times, filter to obtain silica microspheres modified with mercapto groups in the pores, denoted as C 1 . Immerse 0.5g of A1 in 30ml of 2w.t.% cyclohexane solution of trimethylchlorosilane and stir for 6 hours, wash with cyclohexane for 1 to 6 times, filter to obtain methyl-modified silicon oxide microspheres in the pores, denoted as D 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com