Method for separating magnolol and honokiol from magnolia bark

A technology with honokiol and honokiol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult to obtain compound monomers, pollution, tailing, etc., and achieve a large amount of separation , solvent saving, no sample loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

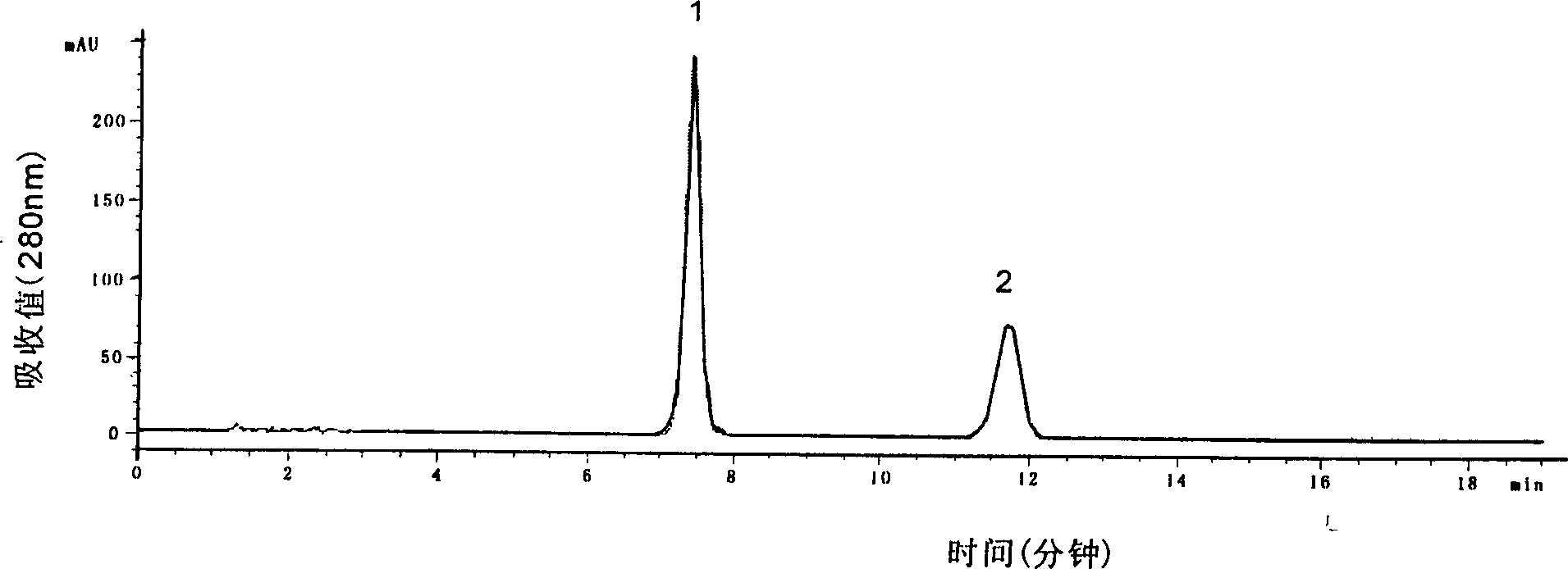

[0020] 1. Heat and reflux 5kg of dried magnolia bark powder with 10L of 65% ethanol for 3 times, each time for 2 hours, filter out the solvent, add 10L of 65% ethanol to the filter residue, repeat the above operation three times, and combine the extracts Concentrate under reduced pressure with a vacuum rotary evaporator to obtain an extract, the concentration temperature is 40 ° C, and after drying, 85 g of crude Magnolia officinalis is obtained. Its composition structure and content are as follows figure 1 As shown, the contents of honokiol and magnolol are 55.4% and 40.1%, respectively.

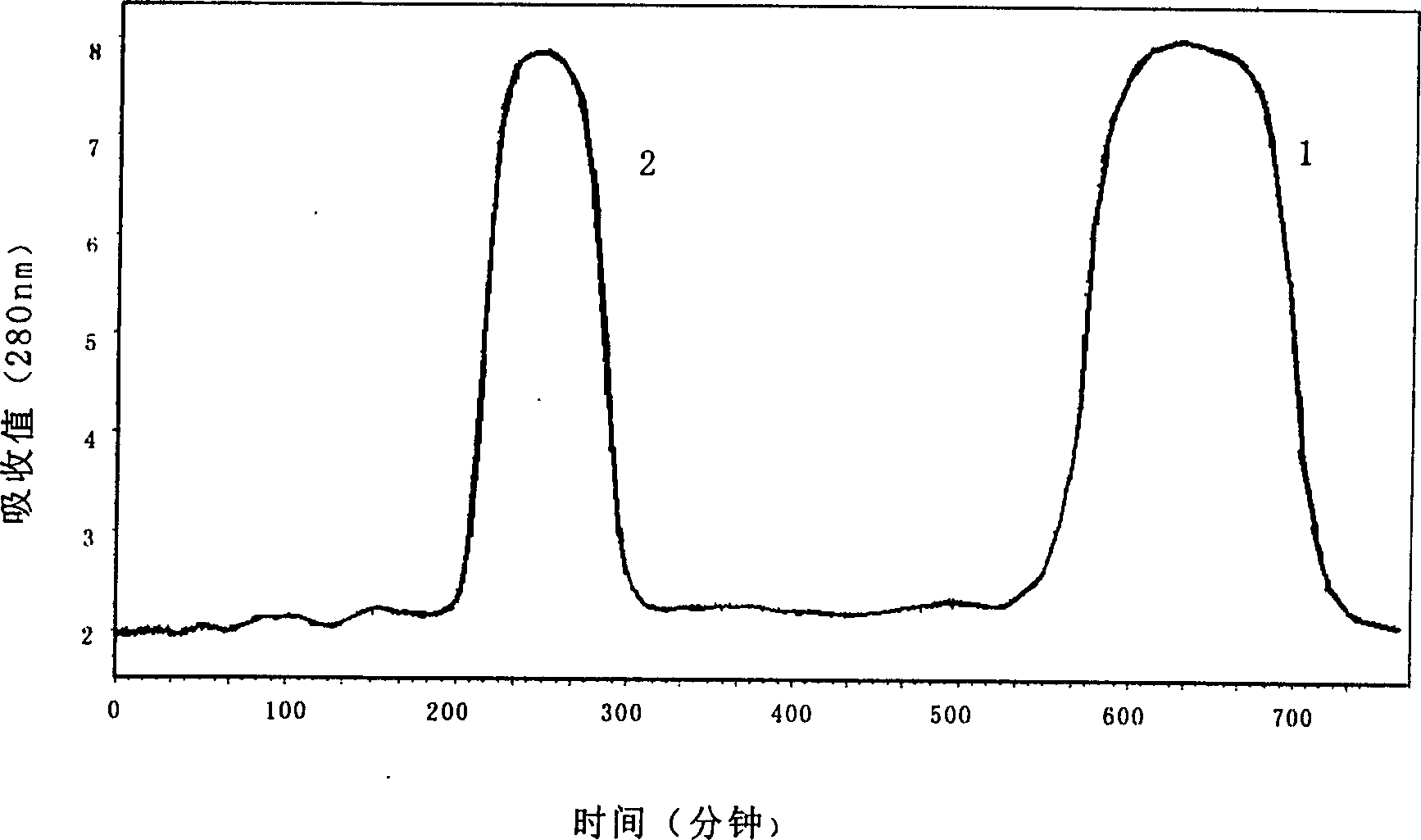

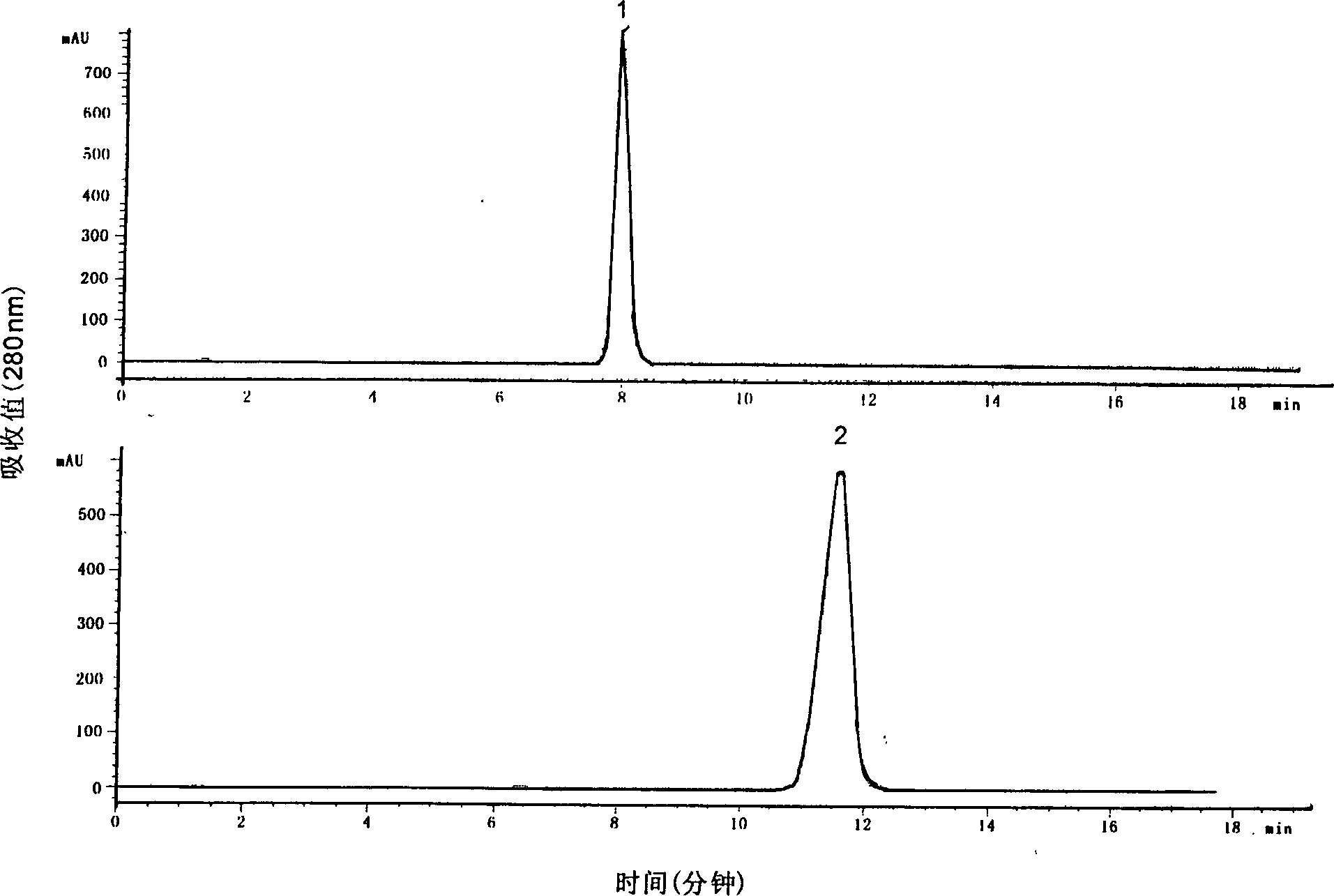

[0021] 2. Separate Magnolia officinalis extract with countercurrent chromatography. Use petroleum ether, ethyl acetate, carbon tetrachloride, methanol and water to prepare a two-phase solvent in a volume ratio of 1:1:8:6:1, and separate the upper and lower phases by standing in a liquid separation container. Dissolve 1500 mg of Magnolia officinalis in 7 ml of the upper phase and 7 ml of t...

Embodiment 2

[0023] The preparation method of the crude Magnolia officinalis is the same as in Example 1, and the Magnolia officinalis extract is separated by countercurrent chromatography. Prepare a two-phase solvent with ethyl acetate, carbon tetrachloride, methanol and water in a volume ratio of 1:6:4:1, and separate the upper and lower phases by standing in a liquid separation container. Dissolve 500 mg of magnolia bark in 5 ml of the upper phase and 5 ml of the lower phase to form a sample solution. The internal diameter of the countercurrent chromatographic column is 4mm, and the column volume is 1600ml. The above phase is used as the stationary phase, and the lower phase is the mobile phase. After the separation column of the countercurrent chromatograph is filled with the stationary phase, the sample solution is injected into the sampling loop of the countercurrent chromatograph, and the countercurrent chromatograph is turned on at a speed of 300 rpm. The flow velocity of 5ml / min ...

Embodiment 3

[0025] The preparation method of the crude Magnolia officinalis is the same as in Example 1, and the Magnolia officinalis extract is separated by countercurrent chromatography. Prepare a two-phase solvent with diethyl ether, ethyl acetate, carbon tetrachloride, methanol and water at a volume ratio of 0.5:0.5:5:4:1, and separate the upper and lower phases by standing in a liquid separation container. Dissolve 180 mg of crude Magnolia officinalis in 3 ml of the upper phase and 3 ml of the lower phase to form a sample solution. The internal diameter of the countercurrent chromatographic column is 2mm, and the column volume is 380ml. The above phase is used as the stationary phase, and the lower phase is the mobile phase. After the separation column of the countercurrent chromatograph is filled with the stationary phase, the sample solution is injected into the sampling loop of the countercurrent chromatograph, and the countercurrent chromatograph is turned on at a speed of 600 rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com