Electric arc length automatic controlling means in tungsten electrode argon-arc welding

A technology of argon tungsten arc welding and arc length, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting control accuracy, inconvenient operation, and poor anti-drying ability, and achieves simple control method, control High precision and sensitivity, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

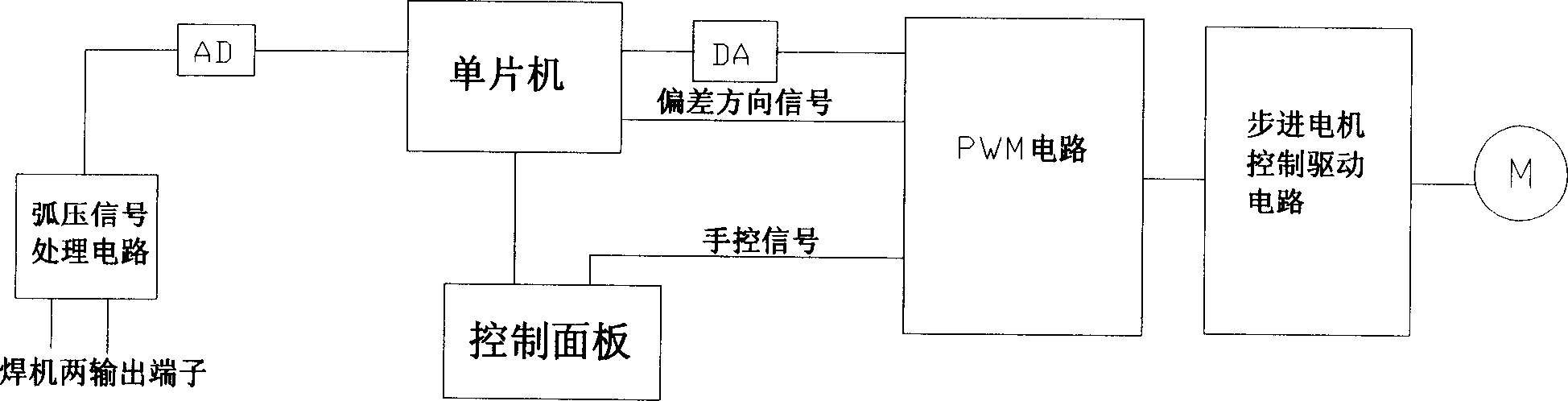

[0013] Embodiment 1, the basic structure of the present invention can be divided into four parts: arc voltage signal processing circuit, single-chip signal processing, PWM generation circuit, stepper motor drive circuit. The AD output of the arc voltage signal processing circuit connected to the two output terminals of the welding machine is connected to the single-chip microcomputer, and the DA signal output of the single-chip microcomputer is connected to the PWM generation circuit and connected to the stepping motor driving circuit and connected to the stepping motor. It adopts the method of combining hardware and software, by using the external characteristics of the welding machine, that is, the arc length and arc voltage are in a linear relationship, and judging the arc length change by judging the arc voltage deviation, thereby realizing automatic control of the arc length. The arc voltage change is detected by the hardware circuit, and the arc length is adjusted when th...

Embodiment 2

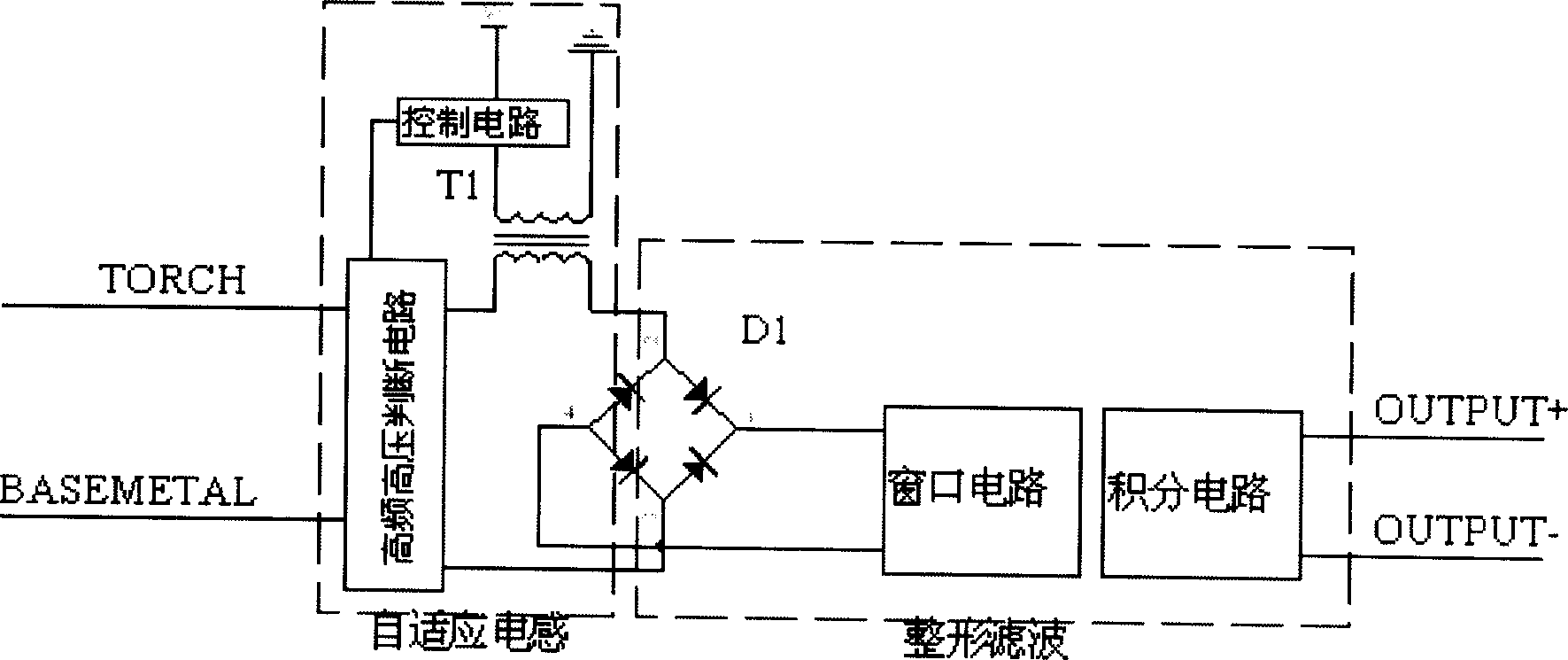

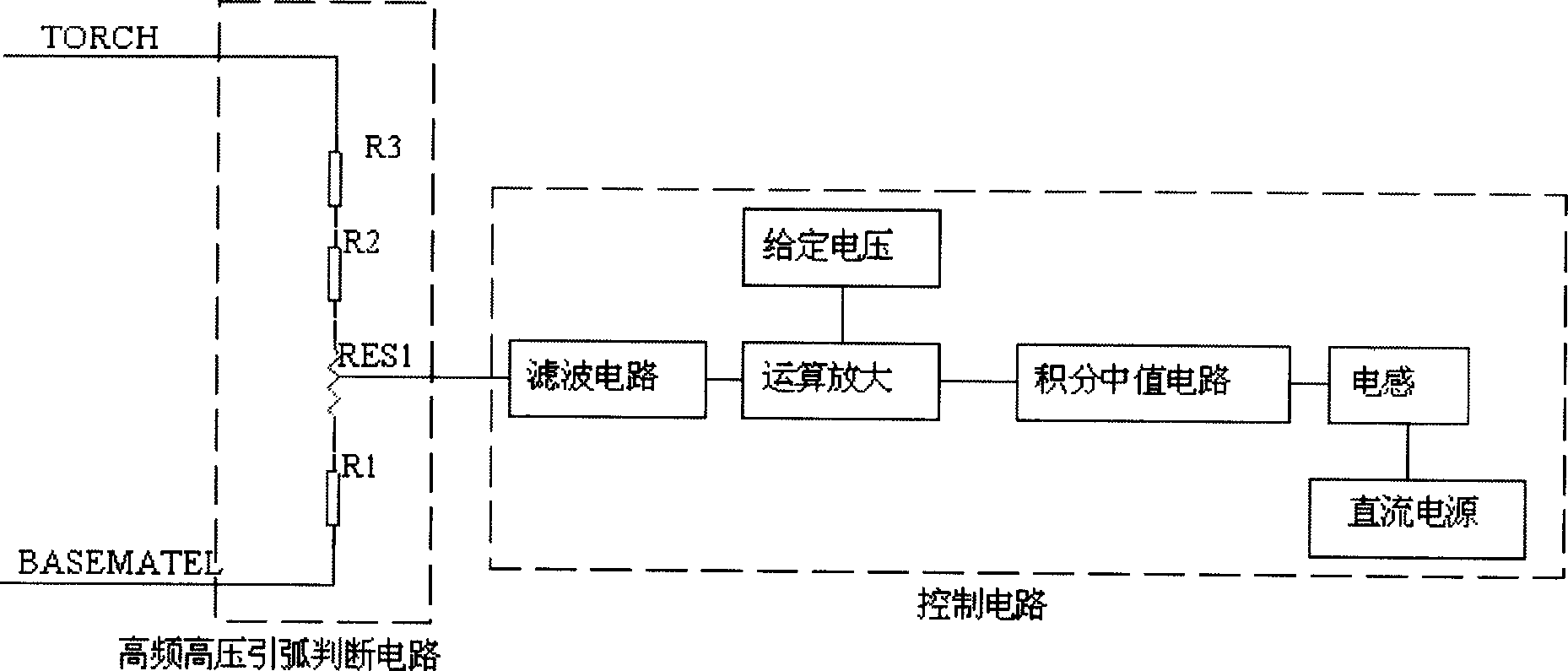

[0017] Embodiment 2, the arc voltage signal processing circuit of the butt welding machine is preprocessed by the adaptive inductance circuit to obtain the linear relationship between the arc length and the output voltage; It is judged whether the arc is in arc ignition, arc extinguishment or normal welding state, and then integrates and filters the signal of the previous stage through the integral circuit to increase the driving capability output of the subsequent circuit. The self-adaptive inductance circuit compares and amplifies the arc voltage signal of the two output terminals of the welding machine with a given voltage, and then connects with a differential median circuit to control the inductance. When the high-frequency arc is struck, the inductance is in a strong saturation state, which avoids the influence of high-frequency and high voltage on the subsequent circuit, and at the same time ensures the reliability of the arc. When there is no high frequency and high vo...

Embodiment 3

[0026] Embodiment 3, the control panel is connected between the single-chip microcomputer and the PWM circuit. Connect the control panel between the single-chip microcomputer and the PWM circuit. When the deviation exceeds the allowable range, it can be set within a certain range through the control panel. After the time set by the control panel, the single-chip microcomputer DA outputs the corresponding deviation signal. Port P gives the motor rotation direction signal; when the deviation is within the allowable range, the single-chip DA has no signal output, and the motor does not move. refer to figure 1 with figure 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com