Glycosyl grain protein-selenium compound and production thereof

A protein and selenium technology, applied in food preparation, food science, climate change adaptation and other directions, can solve the problem of no uniform standard for selenium demand, and achieve the effect of improving use safety, high affinity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

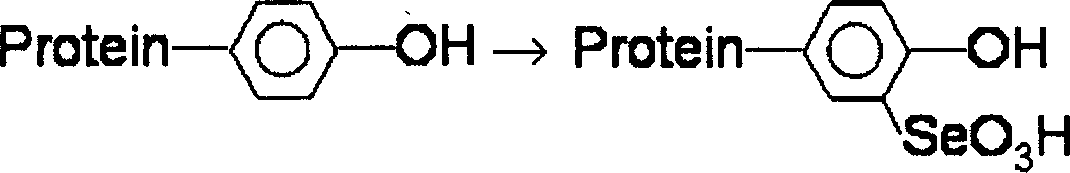

[0027]The preparation of glycosylated cereal protein-selenium complex is carried out in two steps. The first step is to add monosaccharide or disaccharide to the alkaline cereal protein suspension, and make the cereal protein and monosaccharide or disaccharide under high temperature and high pressure conditions. Sugar undergoes Maillard reaction, using side chain amino groups such as glutamine to react with aldehyde groups of monosaccharides or polysaccharides to attach monosaccharide or polysaccharide units to protein molecules, thereby increasing the hydroxyl density of protein molecules. The Maillard reaction between protein and reducing sugar can proceed spontaneously at low temperature, but the reaction time usually takes several days; the reaction can also be carried out at a higher temperature such as 120°C (Brands C.M.J., van BoekelM.A.J.S., Reactions of Monosaccharides during Heating of Sugar-Casein Systems: Building of a Reaction Network Model. J. Agric. Food Chem., 2...

Embodiment 1

[0048] The preparation method of preparing glycosylated cereal protein-selenium element compound with gluten, glucose and selenic acid as raw materials comprises the following steps:

[0049] 1) Take by weighing 20g gluten powder and place it in a beaker, make a 3% suspension with deionized water, add saturated NaOH solution while electromagnetic stirring, adjust the pH value of the suspension to 7, continue stirring at 50°C for 30min, After cooling, add 4g of glucose and stir until the glucose dissolves;

[0050] 2) Put the suspension in a pressure cooker, carry out the glycosylation reaction at 120°C and 0.11MPa for 10 minutes, after cooling, adjust the pH to 5 with saturated acetic acid solution, place it in a dialysis bag and dialyze it with deionized water for 10 hours to remove inorganic Salt;

[0051] 3) Make a 3% suspension of the dialyzed glycosylated cereal protein with deionized water, add 0.6g of selenic acid, stir until the selenic acid is dissolved, react at 5°C...

Embodiment 2

[0053] A preparation method for preparing a glycosylated cereal protein-selenium complex using gluten, mannose, and selenous acid as raw materials comprises the following steps:

[0054] 1) Take by weighing 10g gluten powder and place it in a beaker, make a 15% suspension with deionized water, add saturated NaHCO while electromagnetic stirring 3 Solution, adjust the pH value of the suspension to 12, continue stirring at 90°C for 10 minutes, add 0.5g mannose after cooling, and stir until the mannose dissolves;

[0055] 2) Put the suspension in a pressure cooker, carry out glycosylation reaction at 126°C and 0.15MPa for 2 minutes, after cooling, adjust the pH to 7 with saturated hydrochloric acid solution, put it in a dialysis bag and dialyze it with deionized water for 20 hours to remove inorganic Salt;

[0056] 3) Make a 15% suspension of the dialyzed glycosylated cereal protein with deionized water, add 0.08g of selenous acid, stir until the selenous acid is dissolved, react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com