Production of Redix with siloxane structural unit

A structural unit, epoxy resin technology, applied in the field of epoxy resin preparation, can solve the problems of low silicone content of epoxy resin, difficult to achieve modification and toughening, affecting heat resistance, etc., and achieve good elasticity and flexibility. , Excellent bonding performance, the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

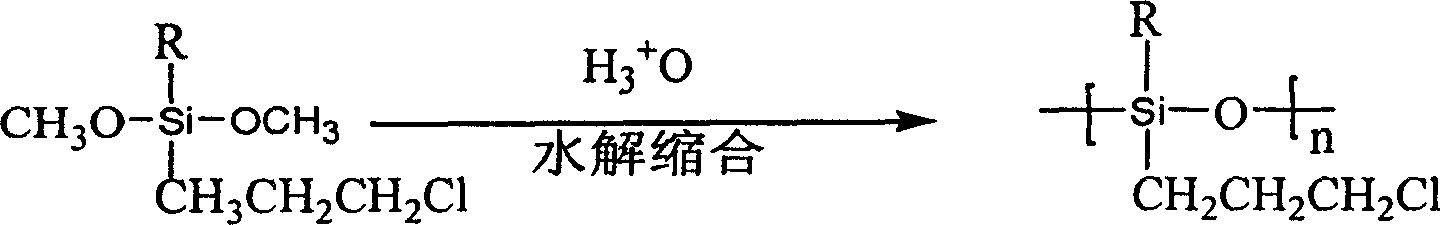

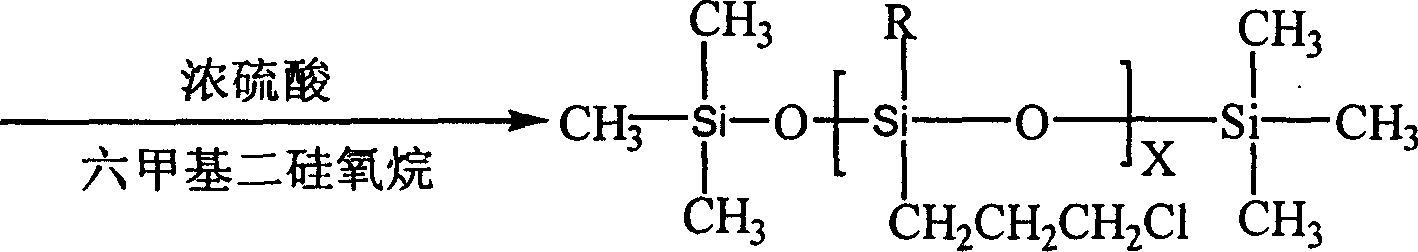

[0032] Example 1.1,1,1,3,5,7,7,7-octamethyl-3,5-di(γ-chloropropyl)-tetrasiloxane (I) and 1,1,1,3 , 5,7,9,9,9-nonamethyl-3,5,7-tris(γ-chloropropyl)-pentasiloxane (II) synthesis

[0033] Add 366g of γ-chloropropylmethyldimethoxysilane and 200ml of ether to a 1000ml four-necked bottle, stir to dissolve, add a few drops of concentrated hydrochloric acid to the four-necked bottle, add 200ml dropwise through a separatory funnel while stirring water, and stirred the reaction at room temperature for 2h, then raised the temperature to 40°C and continued the reaction for 2.5h. After standing still, the organic layer was separated, and the aqueous layer was extracted twice with 20 ml of ether, and combined with the organic layer. The organic layer was washed with distilled water until neutral, and then washed with 20 g of anhydrous Na 2 SO 4 Dry and leave overnight. After filtration, the filtrate was transferred to a 500ml round-bottomed flask, and the ether was distilled off by heat...

Embodiment 2

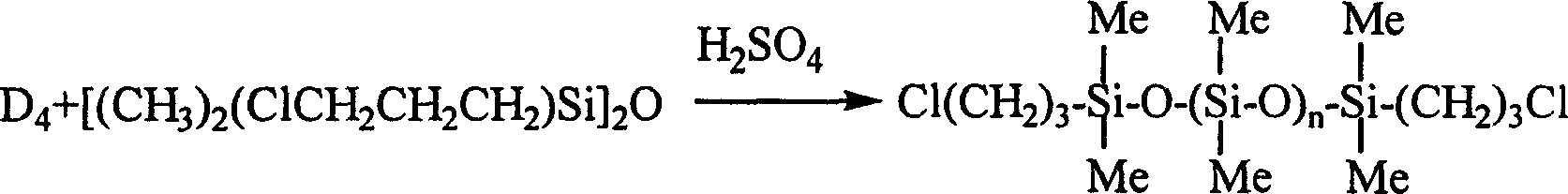

[0036] Example 2. Synthesis of α, ω-dichloropropyl-terminated polydimethylsiloxane oligomers

[0037] In a 250ml four-neck flask equipped with a stirrer, a thermometer and a reflux condenser, add 28.7g 1,3-bis(3-chloropropyl)-1,1,3,3-tetramethyldisiloxane[ For the preparation method, refer to the literature: Jiang Hongqin, Zhang Dunming, Jiang Xiqun, etc., Fine Chemical Industry, 2004, 21 (3): 232], 29.6g octamethylcyclotetrasiloxane (D 4 ) and 1.2g of concentrated sulfuric acid were stirred and reacted at 50°C for 9h. After the reaction, add 60ml 30~60℃ petroleum ether and 10ml distilled water, mix well, separate the water layer with a separatory funnel, wash the organic phase with water until neutral, and then wash it with anhydrous Na 2 SO 4 Let dry overnight. Filter out Na 2 SO 4 , evaporate petroleum ether at normal pressure, and then distill under reduced pressure to steam out unreacted D 4 and other low boiling substances. The residue was a pale yellow liquid wei...

Embodiment 3

[0039] Example 3. Synthesis of α, ω-dichloropropyl-terminated polydimethylsiloxane oligomers

[0040] 59.2 g of octamethylcyclotetrasiloxane was used to replace 29.6 g of octamethylcyclotetrasiloxane in Example 2, and other conditions remained unchanged, Example 2 was repeated to obtain 78.1 g of the product.

[0041] use 1 The molecular weight of the product was measured by HNMR, and the average molecular weight was 933.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com