Perovskite complex oxide and catalyst

A composite oxide and perovskite-type technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the cost of exhaust flow path components Increase and restrict the design freedom of motor vehicles, etc., to achieve the effects of high practical value, reduced temperature reduction, and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Mix lanthanum nitrate, strontium nitrate and iron nitrate so that the molar ratio of lanthanum element, strontium element and iron element is 08:0.2:1. This mixture was added to water to obtain a raw material solution such that the total molar concentration of the lanthanum element, strontium element, and iron element in the liquid was 0.2 mol / L. The temperature of the solution was adjusted to 25°C while stirring the solution, and when the temperature reached 25°C, the pH was adjusted to 8 while adding an ammonium carbonate solution as a precipitating agent. Then, by continuing to stir for 12 hours while maintaining the reaction temperature at 25° C., formation of a precipitate proceeded sufficiently. After filtering and recovering the obtained precipitate, it was washed with water and dried at 110° C., and the obtained powder was called a precursor powder.

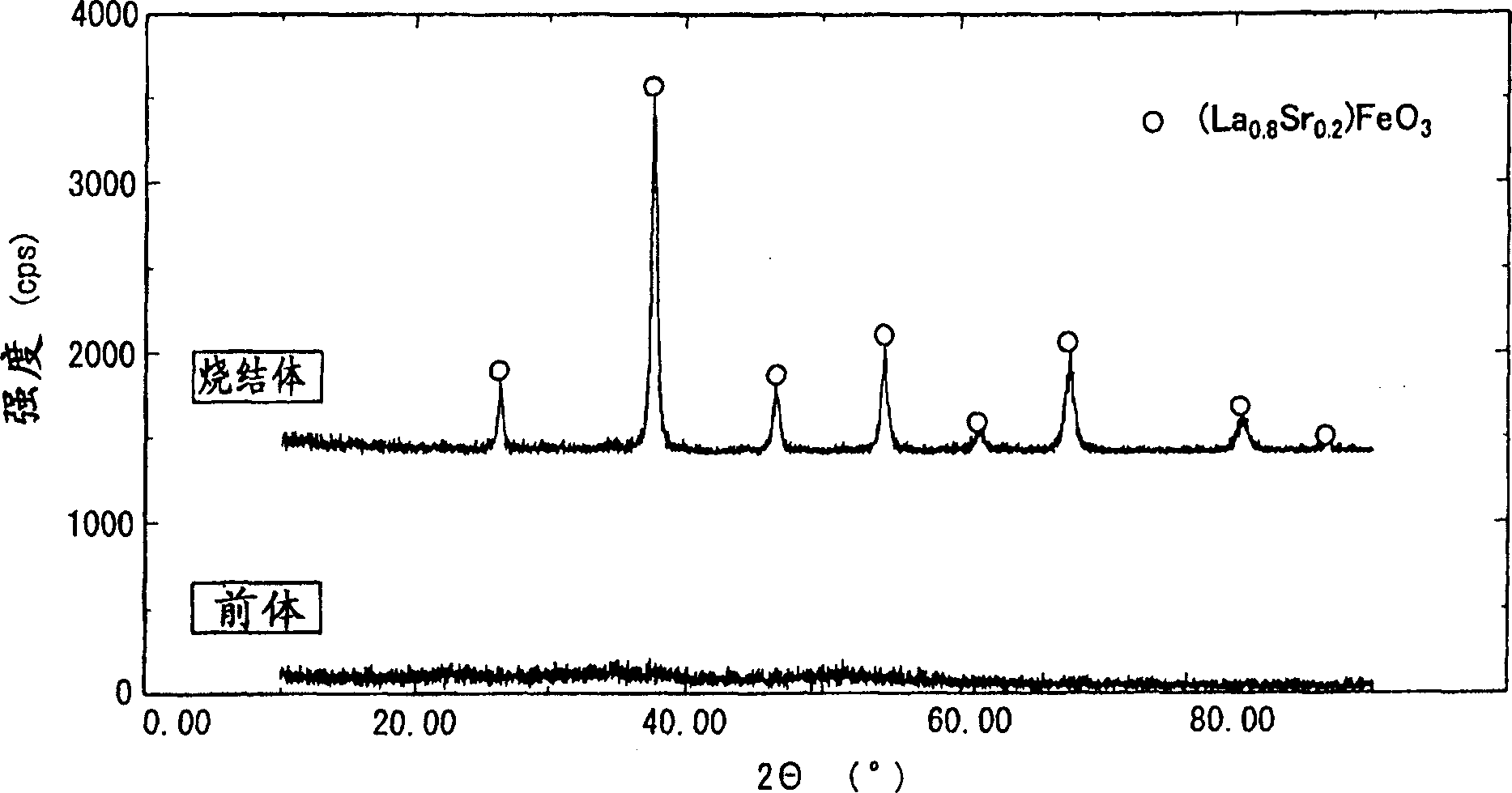

[0044] Perform X-ray powder diffraction of this precursor powder, as figure 1 As shown in , a broad diffractio...

Embodiment 2

[0050] The operation of Example 1 was repeated except that lanthanum nitrate and iron nitrate were mixed so that the molar ratio of lanthanum element and iron element became 1:1.

[0051] X-ray powder diffraction of the obtained sintered body was confirmed to be LaFeO 3 A single-phase perovskite-type composite oxide.

[0052] In addition, thermogravimetric measurement of this perovskite-type composite oxide was performed, and as a result, the weight loss ratio was 32.5%.

Embodiment 3

[0054] The operation of Example 1 was repeated except mixing lanthanum nitrate, strontium nitrate and manganese nitrate so that the molar ratio of lanthanum, strontium and manganese was 0.8:0.2:1.

[0055] X-ray powder diffraction of the obtained sintered body was carried out, and it was confirmed that (La 0.8 Sr 0.2 )MnO 3 A single-phase perovskite-type composite oxide.

[0056] In addition, thermogravimetry of this perovskite-type composite oxide was performed, and as a result, the weight reduction ratio was 33.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com