Hollow microcapsules of polymer in multi-layers, and preparation method

A technology for hollow microcapsules and polymers, which is applied in the field of multilayer polymer hollow microcapsules and their preparation, can solve the problems of thermal stability and chemical stability to be improved, practical application limitations, etc., and achieves broad application prospects and use value. , Simple operation, excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

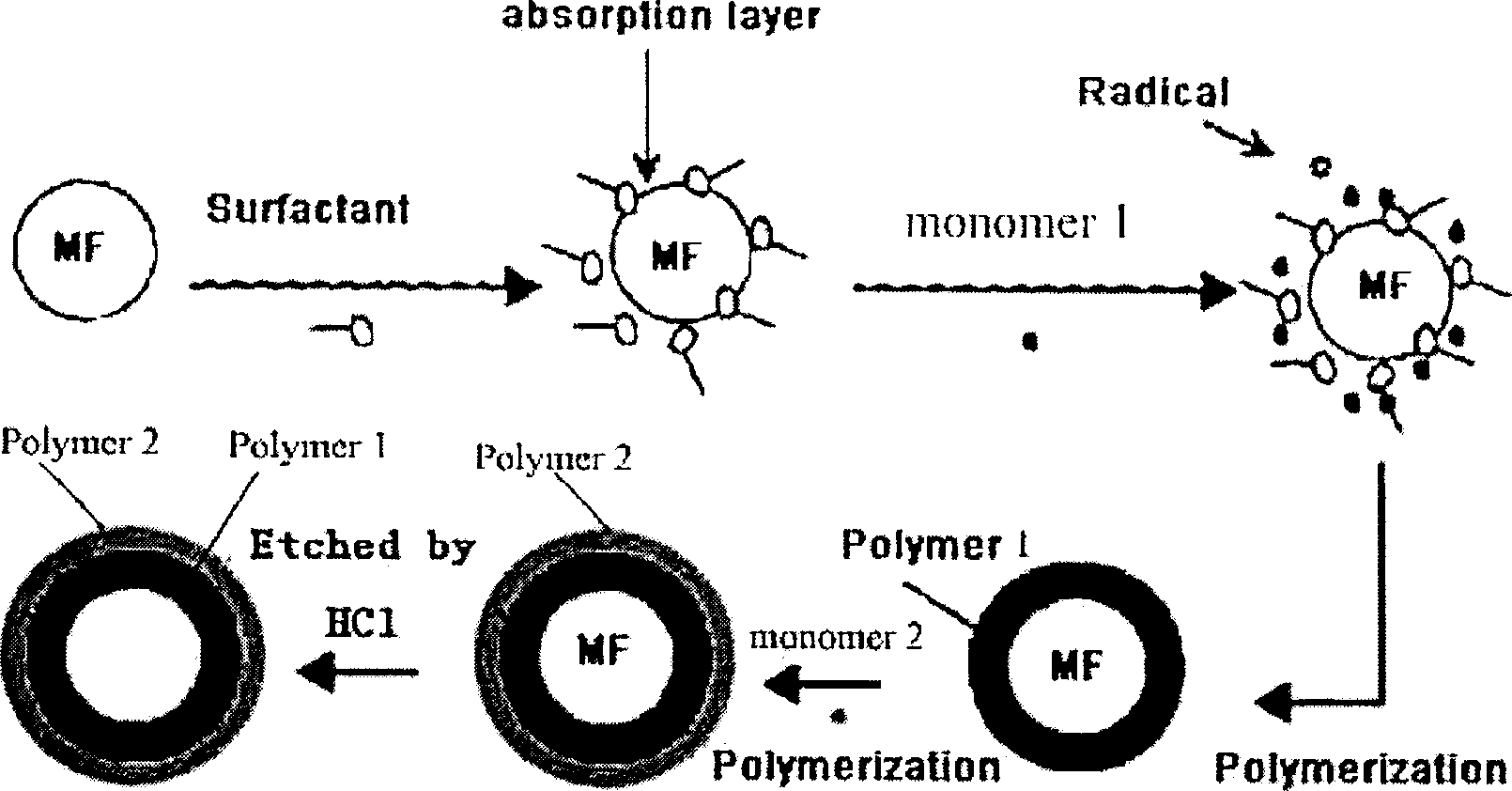

Method used

Image

Examples

Embodiment 1

[0032] Add 14g of melamine and 11g of formaldehyde solution (the molar ratio of the two is 1:3.3) into a three-necked flask equipped with reflux condenser and stirrer, stir and react with a magnetic stirrer in a 60℃ water bath for 20 minutes to obtain prepolymer hydroxyl Methyl melamine. Then add 110 g of deionized water and 0.6 g of polyvinyl alcohol into a 250 mL three-necked flask. After adjusting the pH of the reaction solution to 4.6 with an acetic acid solution in advance, add the prepolymerization solution slowly at 60°C in a water bath, and stir to react 15 The reaction was stopped after 5 minutes, and quickly cooled in ice water. The obtained product dispersion system was centrifuged and settled under the condition of 3500 rpm, the supernatant was removed and then deionized water was added to redisperse. This process was repeated 4 times, and the sample was stored at low temperature to obtain MF nanoparticles.

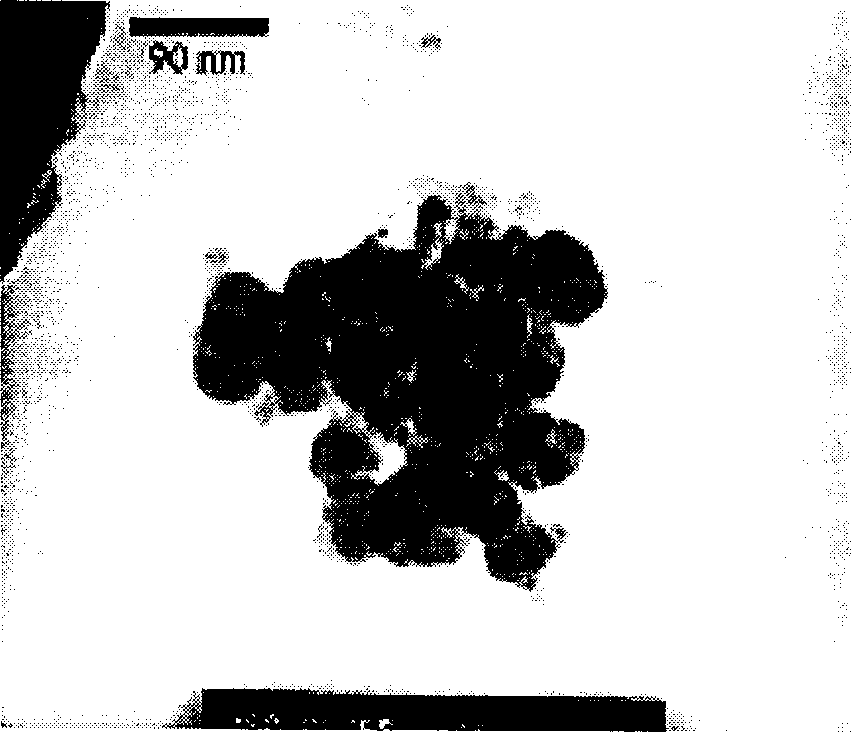

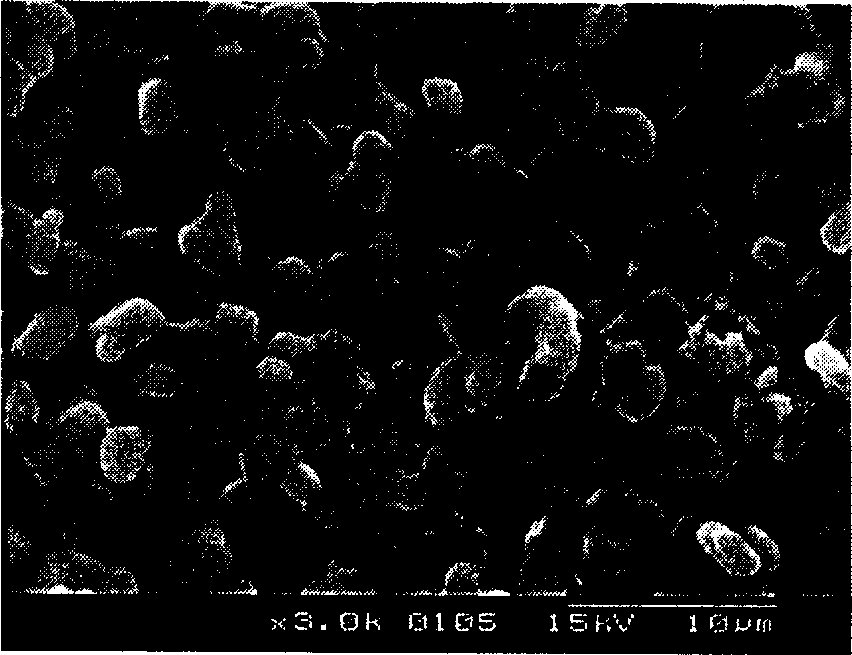

[0033] Weigh 3.5 g of the alcohol solution of MF nanoparticl...

Embodiment 2

[0037] Same as Example 1, but the concentration of KH-570 was changed to 0.05 g / mL, and the amounts of vinyl imidazole and aniline monomers were changed to 15 mL and 10 mL.

Embodiment 3

[0039] The same as Example 1, but the concentration of KH-570 was changed to 0.1 g / mL, and the amounts of vinyl imidazole and aniline monomers were changed to 30 mL and 20 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com