Ultrasonic method for synthesizing mesoporous monox nanometer ball carrier material

A technology of mesoporous silicon oxide and carrier materials, applied in the fields of silicon oxide, silicon dioxide, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: 0.5 g of surfactant cetyltrimethylammonium bromide (CTAB) was dissolved in a mixed system of 120 ml of water and 20 ml of ethanol at room temperature, and cooled to room temperature. 4.0ml of ammonia water was added thereto, and then 1.05g of tetraethyl orthosilicate was quickly added to the above solution and stirred for 2 minutes. The reaction system was placed under an ultrasonic system with a frequency of 20 KHZ and a power of 40 watts for 2 h at room temperature.

[0023] Filter the reacted white mixed solution to obtain a white powder, wash it repeatedly with water and ethanol for 6-9 times, and then dry it in the air at room temperature or in an oven at 50°C-60°C.

[0024] The dried samples were calcined at 500° C. to 550° C. for 5 hours to remove the surfactant and obtain mesoporous silica spheres.

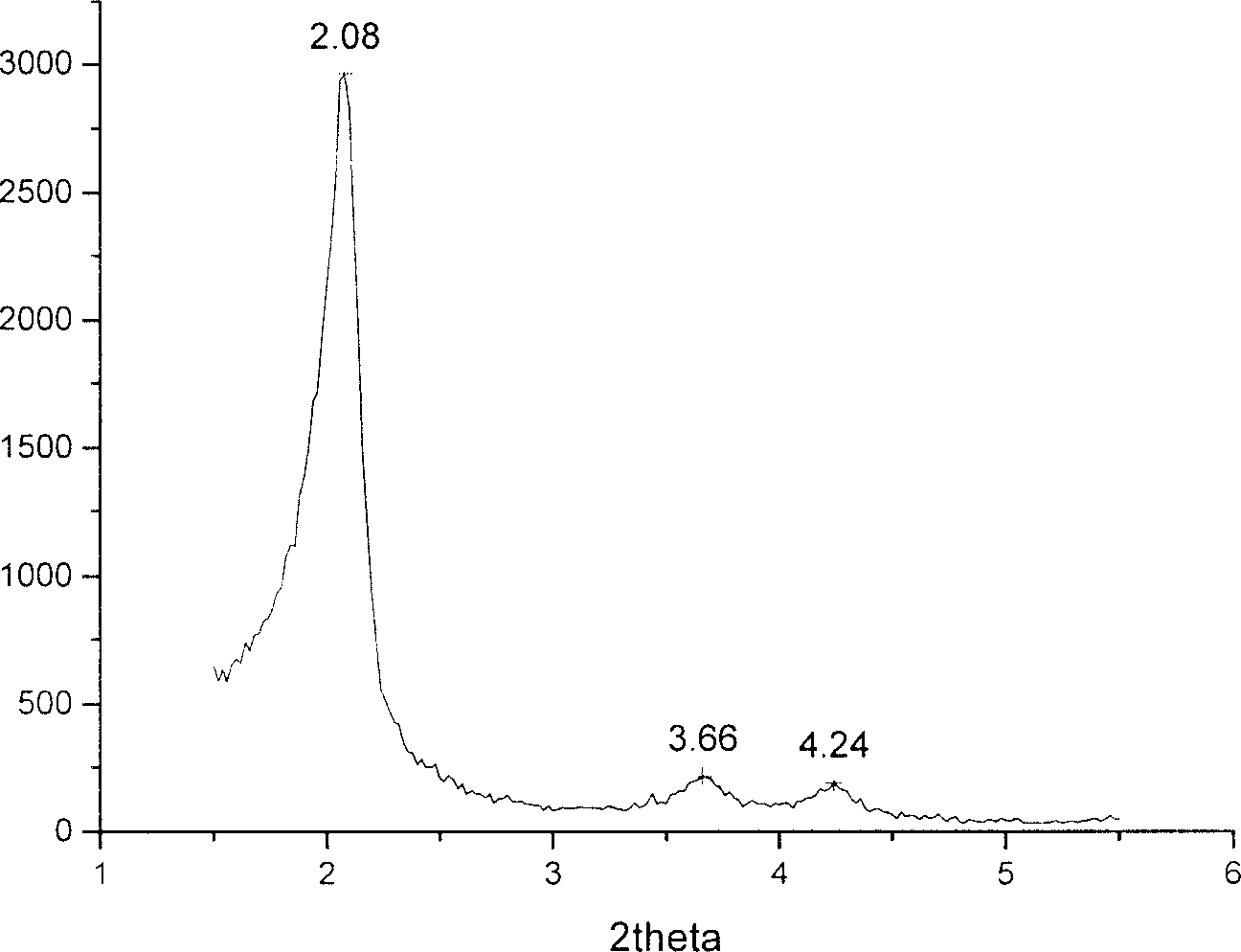

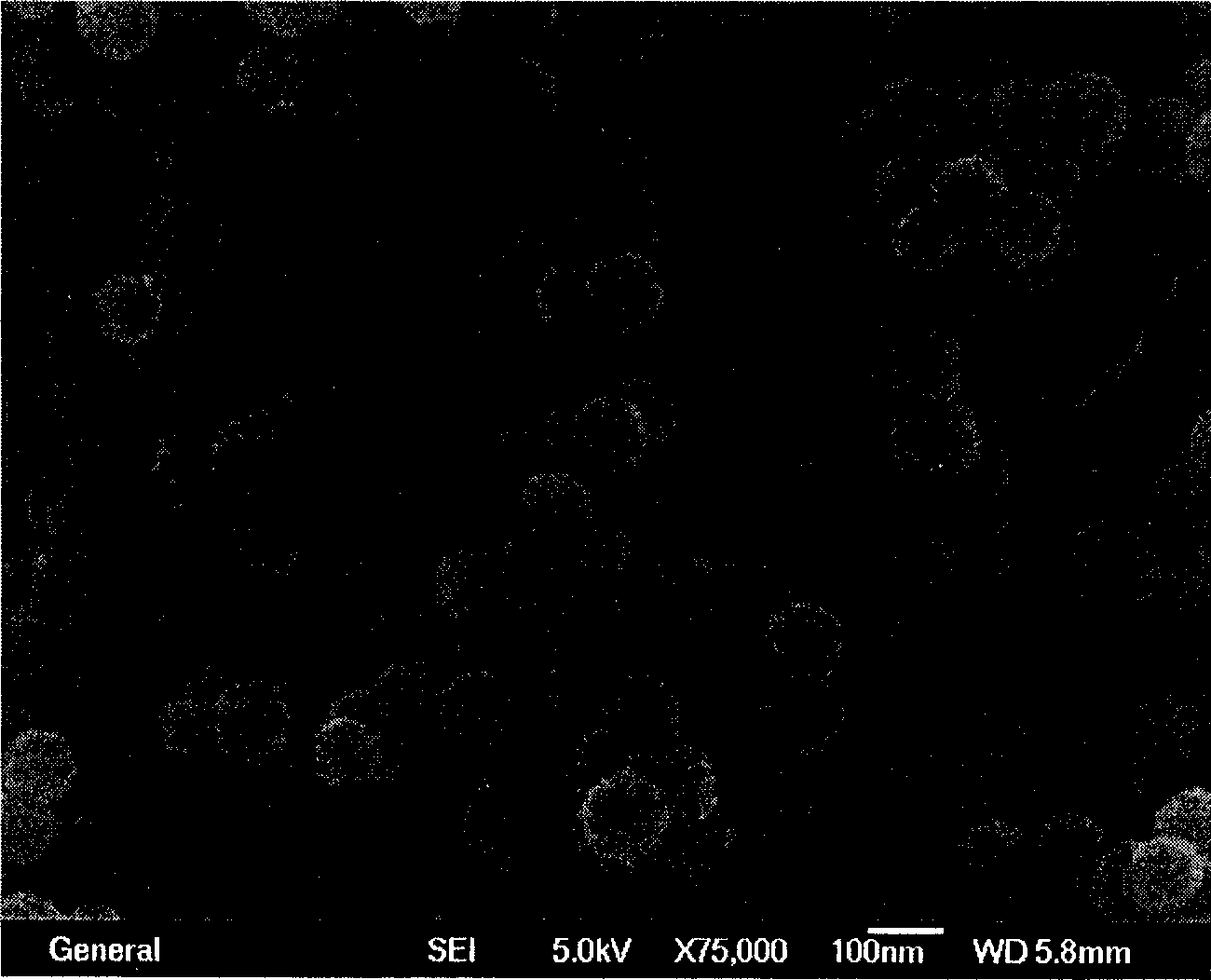

[0025] From the scanning electron microscope (SEM) photos, it can be known that the obtained mesoporous silica spheres have a diameter of about 500 nm. ...

Embodiment 2

[0030] Embodiment 2: Each process is as shown in Embodiment 1, but the ultrasonic time is changed to 6h. The results show that the size of the obtained mesoporous silica spheres is about 300nm, and the pore diameter and structure are similar to those of Example 1.

Embodiment 3

[0031] Embodiment 3: Each process is as shown in Embodiment 1, but the ultrasonic time is changed to 8h. The results show that the size of the obtained mesoporous silica spheres is about 150 nm, and the pore diameter and structure are similar to the results of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com